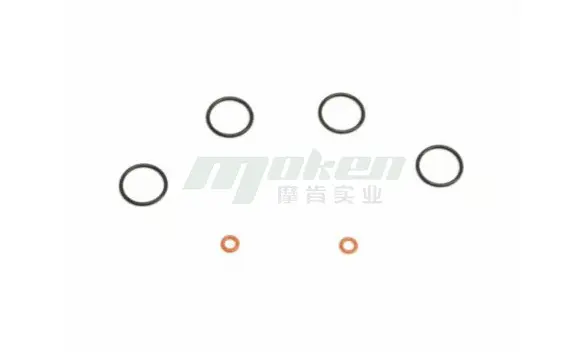

The Smallest Size Silicone Rubber O-ring

-

01- Ultra-small Size: Breaking through the conventional limits, it has achieved extremely small wire diameter and inner diameter, which can meet the application scenarios with extremely stringent requirements for space.- High Precision: Advanced mold design and manufacturing processes are adopted to ensure that the dimensional tolerances are controlled within an extremely small range. This enables precise dimensional control and ensures that the specifications of each O-ring meet strict standards.- Excellent Resilience: The silicone rubber material itself has good elasticity. Even after undergoing multiple compressions and stretches, it can quickly return to its original shape, ensuring the long-term stability of the sealing performance.

01- Ultra-small Size: Breaking through the conventional limits, it has achieved extremely small wire diameter and inner diameter, which can meet the application scenarios with extremely stringent requirements for space.- High Precision: Advanced mold design and manufacturing processes are adopted to ensure that the dimensional tolerances are controlled within an extremely small range. This enables precise dimensional control and ensures that the specifications of each O-ring meet strict standards.- Excellent Resilience: The silicone rubber material itself has good elasticity. Even after undergoing multiple compressions and stretches, it can quickly return to its original shape, ensuring the long-term stability of the sealing performance. -

02- Superior Chemical Stability: It has strong tolerance to common chemical substances such as acids, alkalis, and solvents. It can maintain stable performance in different chemical environments and will not easily age, deform, or corrode.- Good Temperature Resistance: Silicone rubber can maintain stable performance within a wide temperature range. Generally, it can withstand temperature changes from -50°C to 250°C and can adapt to different environments, including both high and low temperatures.

02- Superior Chemical Stability: It has strong tolerance to common chemical substances such as acids, alkalis, and solvents. It can maintain stable performance in different chemical environments and will not easily age, deform, or corrode.- Good Temperature Resistance: Silicone rubber can maintain stable performance within a wide temperature range. Generally, it can withstand temperature changes from -50°C to 250°C and can adapt to different environments, including both high and low temperatures.

-

Functions

01- Efficient Sealing: It closely adheres to the sealing surface, effectively preventing the leakage and intrusion of liquids, gases, and dust. For example, in electronic devices, it can prevent water vapor from entering and avoid short circuits in the internal circuits.- Adaptability to Narrow Spaces: With its ultra-small size, it can be installed between the components with narrow internal spaces in precision instruments, electronic devices, etc., achieving precise sealing. For instance, it plays a crucial role in the key parts inside mobile phones and tablets.- Ensuring Stable Operation of Equipment: In various instruments and equipment, it maintains the stability of the internal environment, prevents interference from external factors, and ensures the high-precision operation of the equipment. For example, in optical instruments and micro sensors, it ensures the accuracy of measurements. -

Advantages

02- Exquisite Craftsmanship: Professional mold designers, material engineers, and product engineers work together. Combining the needs of customers at the usage end, they conduct full-process control from the design of rubber formulas, the design of product dimensional tolerances and structures to mold development, and independently complete the PPAP (Production Part Approval Process). The manufacturing process is impeccable.- Reliable Quality: During the production process, microscopes are used for quality inspection. Every product detail is strictly controlled to ensure that the product quality reaches high-end standards, with strong resilience and excellent sealing performance.- Wide Application Range: The products are widely used in various industries such as food, drinking water, bathroom, sanitary ware, automotive, gas, electronics and electrical appliances, chemical industry, aerospace, hardware machinery, pneumatic and hydraulic systems, etc., meeting the diversified needs of different industries.

-

Application Scenarios

01- Electronic Devices: For consumer electronic products such as mobile phones and tablets, it is used to protect the internal circuits from water vapor and dust, ensuring the normal operation of the devices. In the folding motors of automotive rearview mirrors and rearview devices, it prevents the external environment from damaging the motors and circuits.- Precision Instruments: In devices such as optical instruments and micro sensors, it safeguards the high-precision environment inside the instruments, avoiding the interference of external impurities with the measurement accuracy, and ensuring that the instruments operate stably with high precision.- Medical Devices: It is used for the sealing of components of various small medical devices, ensuring the safe and reliable operation of medical equipment, preventing the intrusion of pollutants such as bacteria and liquids, and safeguarding the safety of patients. -

Application Environment

02- Temperature Environment: It can work stably in the temperature range from -50°C to 250°C. Whether in a cold low-temperature environment or a high-temperature working scenario, it can maintain good sealing performance and physical properties.- Chemical Environment: It is suitable for most conventional chemical environments and has good resistance to the erosion of common chemical substances. It can function normally in the equipment sealing of the chemical industry and in the environments where various chemical substances are present in electronic devices.- Space Environment: It is especially suitable for environments with narrow spaces and extremely high requirements for the size of sealing parts, and can achieve efficient sealing in the compact structures inside precision instruments.