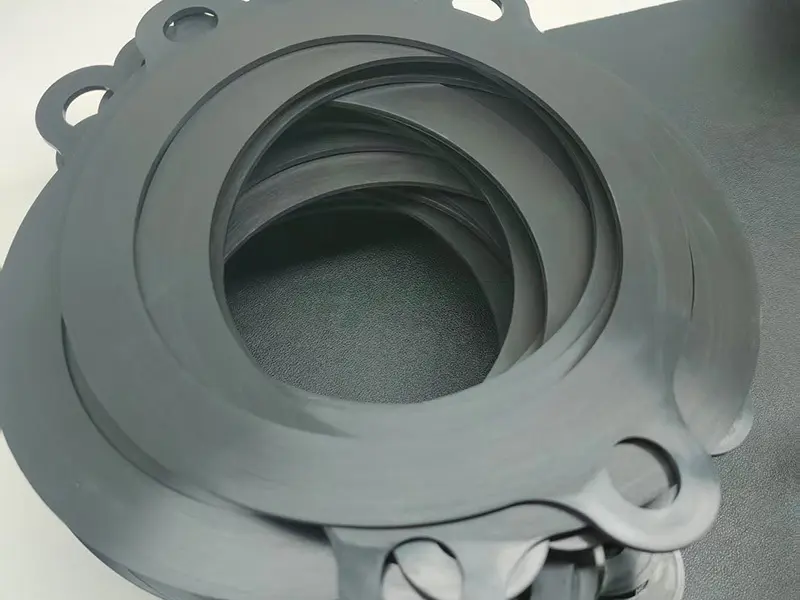

Rubber Seals for Construction Machinery and Equipment

-

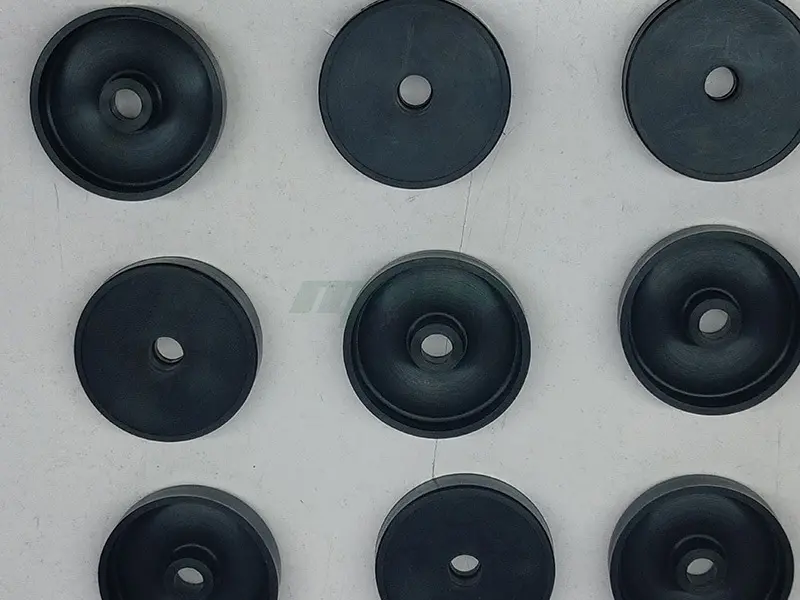

011. Type seals: the most widely used rotary / reciprocating seals for hydraulic cylinders, gearboxes and other scenarios.2. Oil seals (rotary shaft lip seals): used for sealing between rotary shafts and housings, e.g. engine crankshafts, gearbox input shafts.

011. Type seals: the most widely used rotary / reciprocating seals for hydraulic cylinders, gearboxes and other scenarios.2. Oil seals (rotary shaft lip seals): used for sealing between rotary shafts and housings, e.g. engine crankshafts, gearbox input shafts. -

023. Combination seals: made of rubber and metal/plastic combination, such as Stepseal, Glacier Gasket, suitable for high-pressure, high-speed conditions. Rubber Cloth Seal Structure: Nitrile rubber and high-strength fibre cloth composite, compressive strength increased by 40% (up to 35MPa), the coefficient of friction is reduced to 0.12 (reciprocating motion) used in hydraulic cylinder piston rod sealing, rotary joint liner.

023. Combination seals: made of rubber and metal/plastic combination, such as Stepseal, Glacier Gasket, suitable for high-pressure, high-speed conditions. Rubber Cloth Seal Structure: Nitrile rubber and high-strength fibre cloth composite, compressive strength increased by 40% (up to 35MPa), the coefficient of friction is reduced to 0.12 (reciprocating motion) used in hydraulic cylinder piston rod sealing, rotary joint liner. -

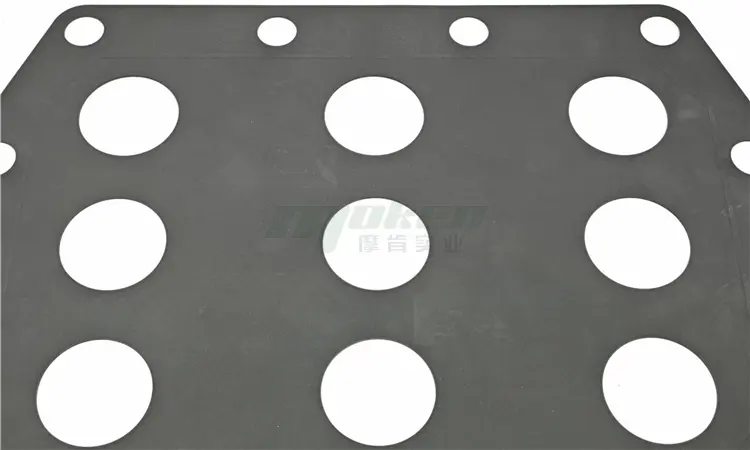

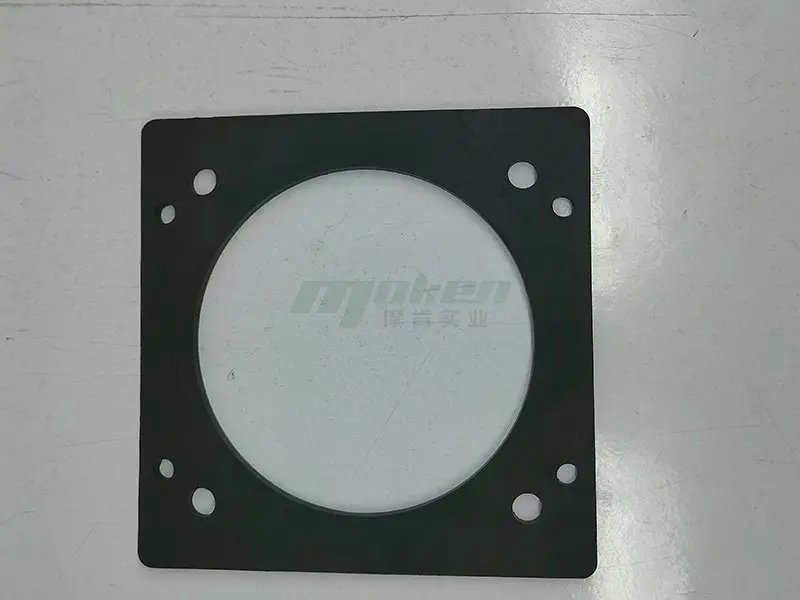

034. Gaskets and sealing gaskets: used for flange, joint surface static sealing, such as cylinder head gasket, hydraulic valve block sealing.5. Shaped parts type: star ring, rectangular ring, diaphragm piece

034. Gaskets and sealing gaskets: used for flange, joint surface static sealing, such as cylinder head gasket, hydraulic valve block sealing.5. Shaped parts type: star ring, rectangular ring, diaphragm piece

-

01

011.Hydraulic system

Application: excavator hydraulic cylinder, crane hydraulic pump, shield machine propulsion system.Environmental characteristics:Pressure range: 10-40 MPa (up to 70 MPa for high pressure system)Temperature range: -40 ℃ ~ +120 ℃ (special conditions up to - 80 ℃ ~ +300 ℃)Medium: mineral oil, synthetic hydraulic oil, water glycol, phosphate esterSpecial requirements: high-pressure pulse, anti-cavitation, anti-shear deformation -

2.Transmission system

02Application: transmission, transfer case, gear box.Environmental characteristics:Speed: 0~5000 rpm (high speed bearing seal)Temperature: -30℃~+150℃ (significant friction heat generation)Medium: gear oil, grease, coolantSpecial requirements: wear resistance, resistance to oil mist penetration, resistance to centrifugal force deformation -

3.Engine system

03Application: crankshaft oil seal, valve stem seal, turbocharger seal.Environmental characteristics:Temperature: -40℃~+250℃ (turbocharger area)Medium: oil, fuel, coolant, exhaust gasSpecial requirements: high temperature oxidation resistance, chemical corrosion resistance, resistance to alternating loads -

4.Extreme working condition equipment

04Applications: deep sea drilling rigs, polar engineering machinery, mining machinery.Environmental characteristics:Temperature: -60 ℃ ~ +180 ℃ (low-temperature tundra or high-temperature mine)Pressure: deep sea 100 MPa or more hydrostatic pressureMedium: mud, acid gas, high sulphur crude oilSpecial requirements: radiation resistance, hydrolysis resistance, resistance to biodegradation

-

1. Nitrile rubber (NBR)

01Characteristics:Excellent oil resistance (mineral oil, hydraulic oil)Good abrasion resistance and compression deformation resistanceWorking temperature: -40 ℃ ~ +100 ℃ (short-term up to + 120 ℃)Typical applications: hydraulic cylinders, gearbox oil seals. -

2. Fluorine rubber (FKM)

02Characteristics:High temperature resistance (long-term + 200 ℃, short-term + 250 ℃)Resistant to chemical media (acid, alkali, solvent)Excellent anti-aging propertiesTypical applications: turbocharger seals, aviation hydraulic systems -

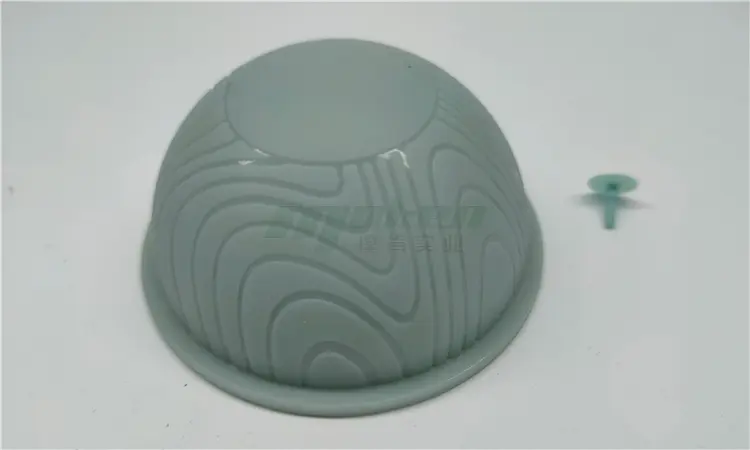

3. Silicone rubber (VMQ)

03Characteristics:Ultra-wide temperature range (-60℃~+230℃)High elasticity and low compression permanent deformationGood electrical insulationTypical applications: low-temperature environment sealing, electronic components protection -

4. Hydrogenated Nitrile Rubber (HNBR)

04Characteristics:Better temperature resistance (+150℃) and weather resistance than NBR.Strong ozone and UV resistanceTypical applications: automotive engine timing oil seals, oil drilling equipment -

5. Polyurethane rubber (PU)

05Characteristics:Extremely high abrasion resistance (3-5 times that of NBR)High tensile strength and tear resistanceWorking Temperature: -30℃~+80Typical applications: hydraulic cylinder piston rod seals for construction machinery. -

6. Cloth sandwich composites

06Very high abrasion resistanceHigh tensile strength and tear resistanceMaterial selection: polyester fibre (temperature resistance + 130℃) and aramid fibre (temperature resistance + 250℃, tear strength increased by 50%)

-

1. Seal structure design

01Compression rate control: static seal compression rate of 15-30%, dynamic seal compression rate of 5-15%.Optimisation of lip angle: the lip angle of lip seal is usually 15°~30° to balance the contact stress and friction.Matching of groove dimensions: following international standards such as IS 3601 (type ring) and IS 6194 (oil seal). -

2.Material Modification Technology

02Nanocomposite reinforcement: adding graphene and carbon nanotubes to enhance wear resistance.Surface coating treatment: PTFE coating reduces the coefficient of friction (from 0.5 to 0.1).Crosslink density control: optimisation of elastic modulus by sulphur/peroxide vulcanisation system. -

3. Dynamic simulation analysis

03Finite element analysis (FEA): simulation of the deformation behaviour of seals under pressure, temperature and strain.Multi-physical field coupling: Considering the effect of thermal - force - chemical coupling on material ageing.Life prediction model: accelerated aging test based on Arrhenius equation (Arrhenius)

-

1. Common Failure Causes

01Material ageing (oxidation, hydrolysis, thermal degradation)Permanent deformation caused by excessive compressionAbrasive wear caused by particle contaminationExtrusion damage caused by pressure impact -

2. Preventive maintenance measures

02Periodic fluid testing (contamination NAS level control)Temperature monitoring (to avoid prolonged over-temperature operation)Seal life cycle management (based on MTBF data) -

3. Solutions for special working conditions

03High-pressure systems: metal bellows-assisted sealingMedia containing solid particles: design of dust lip structureHigh-frequency vibration environment: the use of high damping rubber materials

-

1.Mining dump truck hydraulic cylinder

01Product: Cloth U-ringWorking condition: 35MPa pressure, -30℃ low temperature environmentLife expectancy: 8000 hours without leakage (50% higher than traditional products) -

2.Harbour crane transmission system

02Product: NBR double lip oil sealTechnology: Centrifugal force balanced design, adapting to 4000rpm high speed rotation.Certification: CE certified (EN 13355:2014). -

3.New energy electric loader

03Product: Silicone battery compartment sealCharacteristics: IP69K protection level, electrolyte corrosion resistance.Test: UL 94 V-0 flame retardant certification.

-

01Customisation capability: rapid prototyping (15-day delivery)Supply chain guarantee:Own raw material rubber mixing plantProduction capacity: 40 million standard parts + 20 million customised parts per month.

01Customisation capability: rapid prototyping (15-day delivery)Supply chain guarantee:Own raw material rubber mixing plantProduction capacity: 40 million standard parts + 20 million customised parts per month.

-

011.Intelligent sealing system: integrated pressure/temperature sensors for real-time status monitoring.2. Environmentally friendly material development: bio-based rubber, recyclable seals3. Extreme working conditions breakthrough: ultra-high pressure (>200 MPa), ultra-deep low temperature (-196 ℃ liquid nitrogen environment) sealing technology

011.Intelligent sealing system: integrated pressure/temperature sensors for real-time status monitoring.2. Environmentally friendly material development: bio-based rubber, recyclable seals3. Extreme working conditions breakthrough: ultra-high pressure (>200 MPa), ultra-deep low temperature (-196 ℃ liquid nitrogen environment) sealing technology