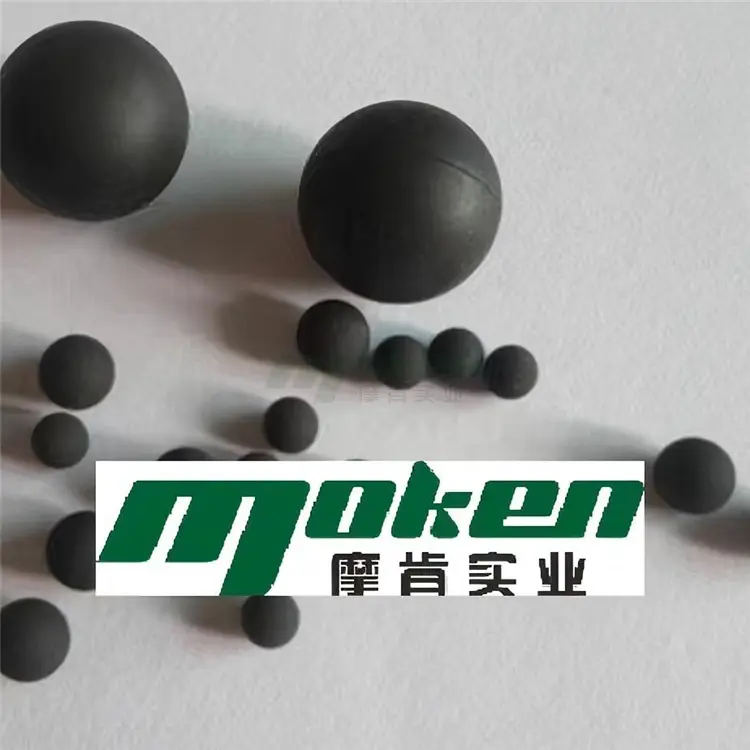

Multi-Purpose Elastic Rubber Sealing Balls

-

01NBR Rubber Balls: They have excellent oil resistance, abrasion resistance, and aging resistance. They are suitable for oil - resistant products such as oil sheets, gaskets, oil - resistant hoses, conveyor belts, and printing rollers.EPM/EPDM Rubber Balls: They feature good aging resistance, ozone resistance, resistance to polar liquids, and excellent electrical properties. They are used in wire coatings, automotive seals, window rubber, conveyor belts, etc.PU Rubber Balls: They have high mechanical strength and are suitable for items that bear strong forces, such as industrial rolls, solid tires, high - pressure packings, and mold pads.

01NBR Rubber Balls: They have excellent oil resistance, abrasion resistance, and aging resistance. They are suitable for oil - resistant products such as oil sheets, gaskets, oil - resistant hoses, conveyor belts, and printing rollers.EPM/EPDM Rubber Balls: They feature good aging resistance, ozone resistance, resistance to polar liquids, and excellent electrical properties. They are used in wire coatings, automotive seals, window rubber, conveyor belts, etc.PU Rubber Balls: They have high mechanical strength and are suitable for items that bear strong forces, such as industrial rolls, solid tires, high - pressure packings, and mold pads. -

02Silicone Rubber Balls (Si): They have outstanding heat and cold resistance as well as good oil resistance. They are used in heat - and cold - resistant scenarios (such as packings, gaskets, oil seals, anti - vibration rubber), and in electrical insulation and the medical field.FPM Rubber Balls: They have excellent heat resistance and chemical resistance. They are suitable for scenarios that require oil and chemical resistance, such as rocket packings, corrosion - resistant packings in chemical plants, hoses, and pump parts.CR Rubber Balls: They have good weather resistance, ozone resistance, and heat resistance, with relatively balanced chemical resistance. They are used in wire coatings, conveyor belts, anti - vibration rubber, adhesives, paints, etc.

02Silicone Rubber Balls (Si): They have outstanding heat and cold resistance as well as good oil resistance. They are used in heat - and cold - resistant scenarios (such as packings, gaskets, oil seals, anti - vibration rubber), and in electrical insulation and the medical field.FPM Rubber Balls: They have excellent heat resistance and chemical resistance. They are suitable for scenarios that require oil and chemical resistance, such as rocket packings, corrosion - resistant packings in chemical plants, hoses, and pump parts.CR Rubber Balls: They have good weather resistance, ozone resistance, and heat resistance, with relatively balanced chemical resistance. They are used in wire coatings, conveyor belts, anti - vibration rubber, adhesives, paints, etc.

-

01

01Production Process

There is usually a mold line (parting line) in the middle of a rubber ball, which may produce flash, affecting the sealing and appearance. Some enterprises (such as Hebei Dingfeng Rubber and Plastic Pipe Industry Co., Ltd.) adopt grinding and polishing processes to make the rubber ball surface smooth, flash - free, with precise roundness tolerance and good sealing effect. -

Quality Inspection

02It includes items such as appearance, dimensions, material properties, and surface roughness to ensure that the product meets the usage requirements.

-

Industrial Field:

01• In vibration screening equipment (such as linear vibrating screens and rotary vibrating screens), rubber balls are key spare parts for anti - blocking screen meshes. They can improve the screen penetration rate by reciprocatingly hitting the screen mesh and also dampen vibration to extend the equipment's service life.• They are widely used in industries such as food, medicine, mining, machinery, metal metallurgy, and grain cleaning machines, meeting the requirements of sealing, abrasion resistance, and chemical corrosion resistance in different scenarios. -

Special Fields:

02• Dock Protection: For example, the super - large floating rubber fenders independently developed by Dalian Dianfeng Group (with an outer diameter of 5700 mm and a length of 6500 mm) use their good reaction force and energy absorption properties to protect ships and docks, suitable for the docking of large - scale ships.• Medical Field: Medical rubber balls (mostly made of natural rubber or silicone rubber) are used to suck up liquids such as liquid medicine, blood, and pus. They are required to have good elasticity, strong airtightness, and be not easy to break, and their surfaces are specially treated to prevent cross - infection.