Oiled Silicone Rubber

Also known as self-lubricating silicone. Oil out of self-lubricating silicone oil performance, lubrication performance is superior, long duration and other characteristics.

Self-lubricating silicone, containing a silicone rubber and silicone rubber incompatible silicone oil, silicone rubber can slowly seep out after curing, with the characteristics of the self-analysis of oil, while having excellent resistance to high and low temperatures, in a wide range of temperatures to maintain constant mechanical properties, can be stored for a long time!

Oil silicone rubber to improve the existing silicone rubber dynamic sealing effect is poor, short service life, the silicone rubber is suitable for moulding, extrusion, injection and other products forming process, vulcanized silicone rubber products out of the oil quickly, the amount of oil is moderate, and make the oil has a certain slow release effect, both to ensure the lubrication effect, but also to improve the service life. The main characteristics of the oil out of self-lubricating silicone rubber is smooth feel, surface finish is relatively high, the face is relatively flat, will not produce sticky dust, wear-resistant performance enhancement, strong adhesion. Secondly, the dustproof silicone products, anti-sticky adhesive properties can take a good role, but also has a low coefficient of viscosity temperature, high compression resistance.

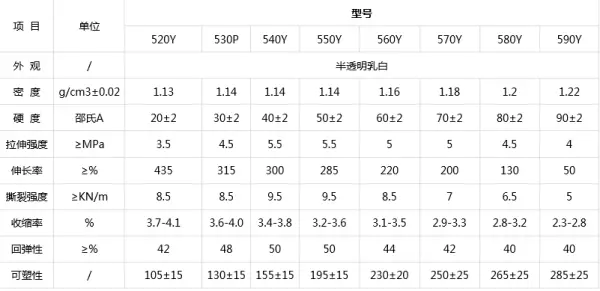

Part of the parameters of the oil silicone:

Surface spraying

Silicone products to maintain the appearance of the common process, it is mainly to enhance the appearance of the product feel, reduce the product adhesion to prevent the product surface appears sticky dust phenomenon, at present, in addition to silicone products, PU, as well as other soft rubber materials can also be used in the way of spraying ink, ink belongs to the anti-static oil is also known as feel the oil, spraying a layer of watery ink on the surface of silicone rubber products in the high temperature adherence in the surface of the product to achieve the Slip soft comfortable effect, this process has long been mature, in a variety of silicone products can be used, electronic products naturally not a problem.

(Enhance the appearance of the product feel, reduce product adhesion to prevent the product surface sticky dust, wear-resistant, prolong the life of the product to reduce static electricity)

Surface Coating

Rubber products have the following characteristics after ptfe tetrafluoro coating:

1. Non-adhesion: almost all substances do not bond with ptfe coated film. Very thin film also shows very good non-adhesive properties.

2. Heat resistance: ptfe coating has excellent heat and low temperature resistance properties. Low temperature (-240 ℃) does not embrittle. High temperature (288 ℃) does not melt. Can work in ~ 200 ℃ ~ 300 ℃ range of normal continuous use, with significant thermal stability, it can work at freezing temperatures without embrittlement, not melting at high temperatures.

3. Sliding: ptfe coating film has a low coefficient of friction. The coefficient of friction changes when the load slides, but the value is only between 0.05-0.15.

4. Moisture resistance: Teflon coated film surface is not stained with water and oil, the production operation is not easy to stain the solution, such as a small amount of dirt, a simple wipe can be removed. Short downtime saves working hours and improves working efficiency.

5. Wear resistance: low coefficient of friction, ptfe coefficient of friction is very low (only 0.02 ~ 0.04) is 140 rubber, with self-slip, under high load, has excellent wear resistance. Under a certain load, with wear resistance and non-stick double advantages.

6. Corrosion resistance: ptfe coating with strong acid, strong alkali, strong oxidants and organic solvents and other properties, almost free from pharmaceutical erosion, can protect parts from any kind of chemical corrosion.

0-ring elastomer ptfe Teflon coating application

o-ring (o ring/o-ring) teflon/ptfe spraying

o-ring ptfe teflon spraying solution for all difficulties

The use of ptfe coating coated on o-ring seals has the following advantages:

First, without the use of lubricants, reduce the coefficient of friction, thus making o-ring seals easy to install, and help prevent o-ring seals from sticking to each other.

Second, the use of lubricants such as oil, talcum powder or silicone oil can be avoided.

Third, it improves the chemical resistance and weather resistance of o-type seals, so that they are protected from corrosion by solvents, salt water and so on.

Fourth, make o-type seals have a colour code for differentiation. ptfe coatings are available in a range of colours, from traditional black to orange.

Fifth, so that o-type seals can be used low-cost rubber substrate, this is mainly due to o-type seals (oring) with the help of coating layer can achieve the desired performance, so that there is no need to use the expensive

This is mainly due to the fact that o-ring(oring) can achieve the desired properties with the help of a coating layer, thus eliminating the need for expensive rubber substrates.

Uniformity of our coating coverage

Teflon spray coating has excellent resistance to high and low temperatures, abrasion resistance, resistance to strong acids and alkalis, insulation, dry lubrication, anti-adhesion and other characteristics, so it is generally applicable to various industrial fields, so that major enterprises to greatly reduce costs, improve production efficiency, Teflon spraying, improve product quality.

Teflon spraying process application characteristics are mainly focused on which aspects? First of all, the selection of this process method can protect the product, after the process, will not cause any damage to the material or the product itself, and at the same time can enhance the grade and quality of the product, so that the performance of the product has a greater progress, so compared with other process methods, the use of Teflon process can better meet the needs of the application of the modern processing places.

Through the Teflon spraying process to carry out production and processing can also avoid adhesion, because this process has the characteristics of non-adhesive, after the completion of the process, the material will not be chemical reaction with other substances, the air duct Teflon spray processing, but also can be firmly adhered to the surface of the material, in the event of changes in temperature and other changes can be maintained in a stable state, so in the process is not subject to the limitations of environmental temperature. These are the benefits of Teflon process.

First of all, in the food processing industry, you can often see the application of Teflon spraying process, the use of this process in the food industry can make the processing process more simple, because in many food processing to avoid the occurrence of adhesion between the ingredients and processing equipment, the rubber surface Teflon spraying, so the choice of process methods to achieve better stability. Teflon spraying process can be avoided and material adhesion, stability is very high, not all sit raw demoulding and other phenomena, so in the production of food processing tools and related materials will be used in the production of this process.