How to Choose the Right Type of Seal for a Specific Application?

The precise matching of seal types for specific industrial and equipment applications is crucial and requires careful consideration of a wide range of real-world conditions. Below are a few dimensions to focus on when carefully selecting seals based on different application scenarios and their specific guiding principles:

1. Adaptability to stressful environments

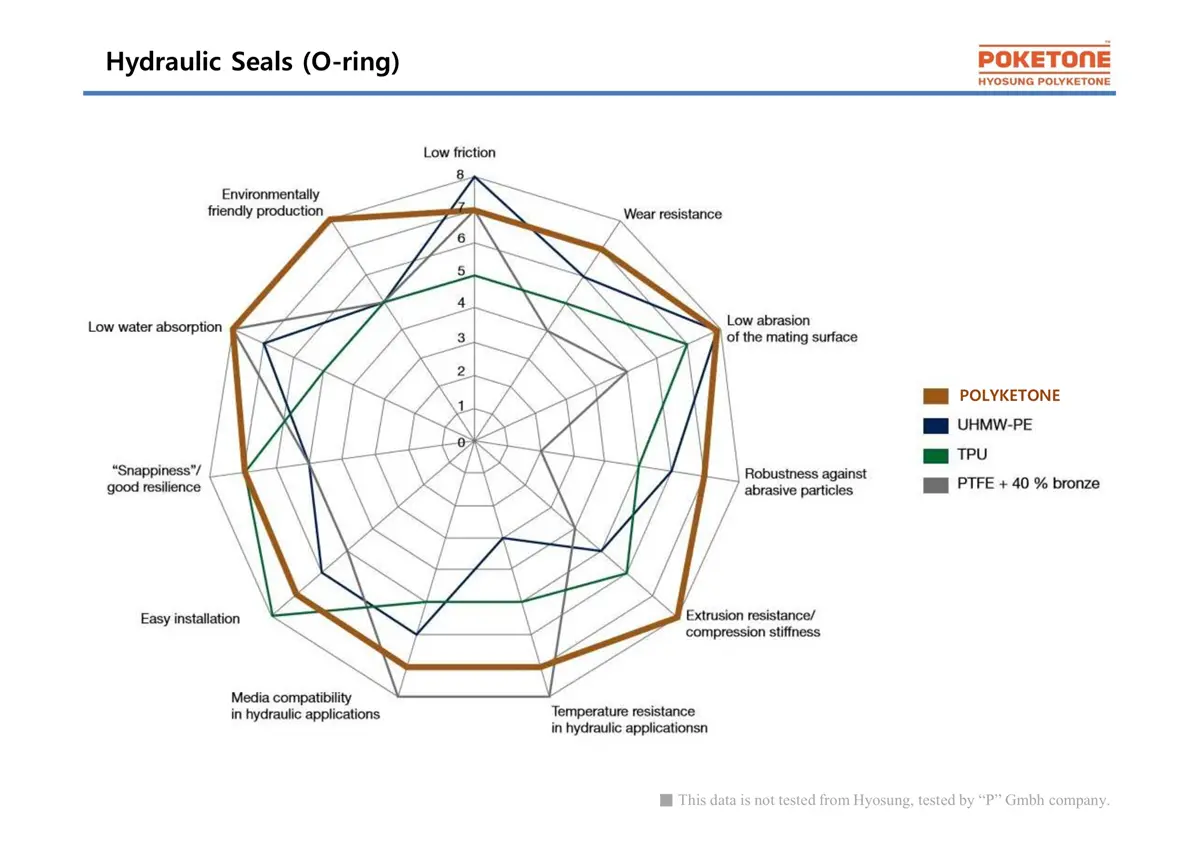

▪ High-pressure challenges: In high-pressure environments such as heavy machinery hydraulics, V-seals and their composite structures are preferred for their excellent pressure resistance, ensuring structural stability and sealing effectiveness.

▪ Low and medium pressure zones: in relatively mild pressure scenarios, such as some light machinery, O-Rings stand out for their simple structure, good sealing performance and cost-effectiveness; Y-Rings are flexible enough to adapt to a wider range of low-pressure applications.

2. Motion Mode Matching

▪ Reciprocating cycles: For components requiring frequent reciprocating movements, such as piston rods, Y- and U-shaped seals reduce friction and wear with their good dynamic adaptation and extend service life.

▪ Rotary seals: for components such as rotating shafts, lip seals can effectively close rotating interfaces and prevent leakage thanks to their unique lip design.

3. Operating Temperature Range

▪ High temperature resistance: In extreme high temperature conditions, such as automotive engines or industrial furnaces, seals made of high temperature resistant materials such as Viton become a necessary choice to guarantee the stable operation of the sealing system.

Low temperature environment: Silicone rubber seals with its excellent cold resistance, in frozen equipment or polar conditions to show excellent performance.

4. Media compatibility

▪ Corrosion resistance: in the face of strong acid, alkali and other corrosive media, PTFE seals with its excellent chemical stability, to ensure sealing safety.

▪ Oil resistance: For lubricating oil, hydraulic oil and other oily media, NBR seals are widely used because of their good oil resistance.

5.Installation space limitation

▪ Compact design: In space-constrained applications, such as inside precision instruments or small equipment, rectangular or miniature seals are ideal because of their compact size.

6. Accuracy and Reliability Requirements

▪ High precision requirements: Aerospace, nuclear and other high-precision fields require seals with extremely high sealing precision and reliability, which may require customised combination sealing solutions.

7. Economic considerations

▪ Cost-effectiveness: Under the premise of meeting all performance requirements, a comprehensive assessment of the cost, select the most cost-effective seal type, help to reduce overall maintenance costs and improve the competitiveness of the equipment.

By accurately analysing multi-dimensional factors such as pressure, movement, temperature, media characteristics, installation space and precision requirements, and combining them with cost-effective considerations, we can tailor the most suitable sealing solutions for different application scenarios, thus ensuring the long-term stable operation and excellent sealing performance of the equipment.

For example, in automotive manufacturing, according to the specific needs of the oil pipeline system, the selection of high temperature resistant and adapt to the limited space of the O-ring; while in the hydraulic system of heavy machinery, prefer to use high-pressure and wear-resistant V-ring.