News

Mokeng (Xiamen) Industrial Co., Ltd. has obtained the WRAS certification.

On June 5, 2025, Mokeng (Xiamen) Industrial Co., Ltd. obtained the WRAS certification. The material used is EPDM70.

New Products at the June Shanghai Expo! Come and Pick Up This Expo Guide

4-6 June 2025 Shanghai HVAC Comfort Systems Exhibition, Conference Proceedings Collection Issue 1_Phoenix Network

How to Choose the Right Type of Seal for a Specific Application?

The precise matching of seal types for specific industrial and equipment applications is crucial and requires careful consideration of a wide range of real-world conditions. Below are a few dimensions to focus on when carefully selecting seals based on different application scenarios and their specific guiding principles

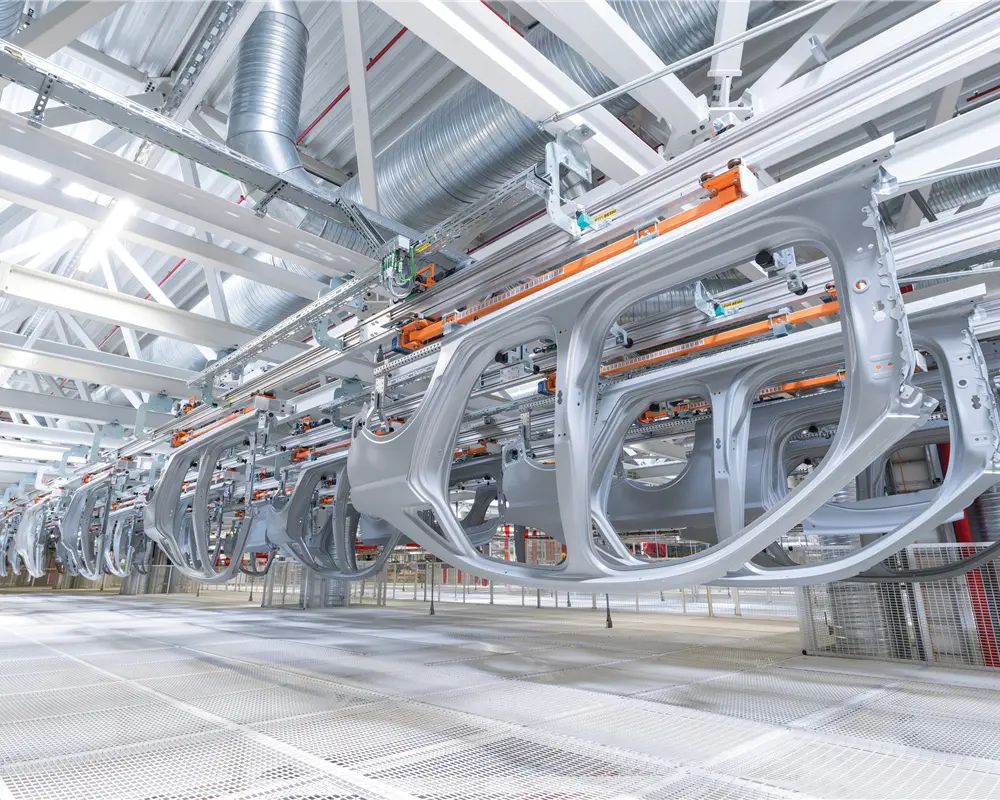

Rubber Automatic Feeder: A Versatile Expert in Rubber and Plastics Production

In the field of rubber and plastics production, efficiency and precision are the keys to the development of enterprises. The rubber automatic feeder introduced by our company is becoming an important force driving production transformation with its outstanding performance.

Rubber Liquid Nitrogen Freezing Trimming Machine: The Precision "Beautician" in the Rubber and Plastics Industry

In the field of rubber and plastic products manufacturing, the rubber liquid nitrogen freezing trimming machine is an indispensable piece of equipment that significantly enhances production efficiency and product quality.

Moken Automatic Inspection Machines: Precise Guardians of Rubber O-Ring Quality

In the field of Rubber O-Ring production, quality inspection is a crucial link to ensure product quality. Morken, with its advanced technology and excellent equipment, has set a new benchmark for the industry. Currently, Moken has six automatic inspection machines for Rubber O-Rings.

Oiled Silicone Rubber

Also known as self-lubricating silicone. Oil out of self-lubricating silicone oil performance, lubrication performance is superior, long duration and other characteristics.

Secondary Vulcanisation

When silicone rubber is vulcanised with peroxide, the decomposition of peroxide triggers the reaction of polymer, which generates low molecular compounds (e.g. benzene and benzoic acid, etc.) present in the rubber that will affect the mechanical properties of the rubber.