The Applications of Rubber in the Drinking Water and Water Purification Industries

In the drinking water and water purification industries, rubber plays a crucial role in various forms, safeguarding water quality safety and the stable operation of equipment.

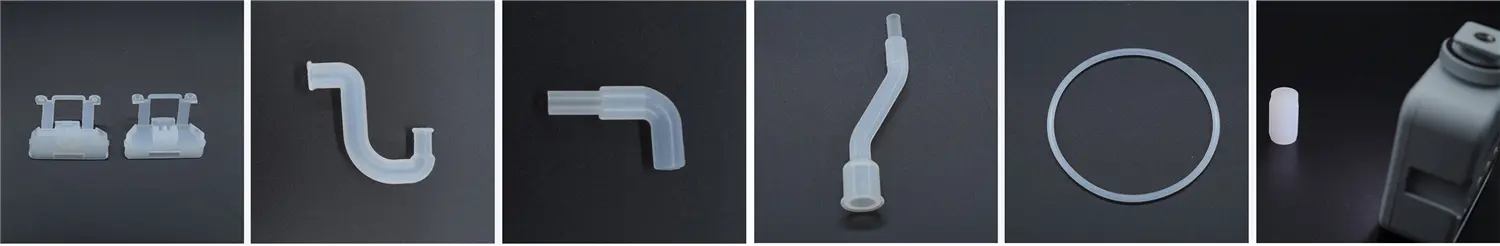

Rubber seals are one of the most widely used rubber products in these industries. At the connections of filter elements, pipe joints, and valve parts of water purification equipment, rubber sealing rings and gaskets can provide reliable sealing performance, preventing water leakage and ensuring the tightness of the entire water purification system. This not only maintains the normal operation of the system but also prevents the intrusion of external impurities, guaranteeing the purity of the treated water.

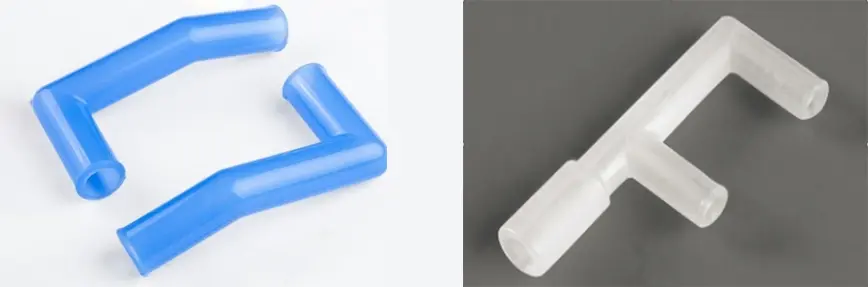

Rubber hoses are also commonly used components. They are used to connect various components of water purification equipment, enabling the smooth flow of water. High-quality rubber hoses have good flexibility and water resistance. They can adapt to different installation environments and water flow pressures, and do not release harmful substances into the water. Meeting the drinking water hygiene standards, they ensure the safe transportation of drinking water.

In addition, rubber diaphragms are indispensable in the pressure control and water flow regulation devices of some water purification equipment. They can precisely control the water flow according to the pressure changes inside the equipment, ensuring the stability and efficiency of the water purification process. For example, in some reverse osmosis water purifiers, rubber diaphragms assist in regulating the pressure, ensuring that water molecules can smoothly pass through the reverse osmosis membrane to effectively remove impurities and salts from the water.

In conclusion, with its excellent properties such as sealing and water resistance, rubber plays an indispensable role in the drinking water and water purification industries, providing people with safe and clean drinking water.