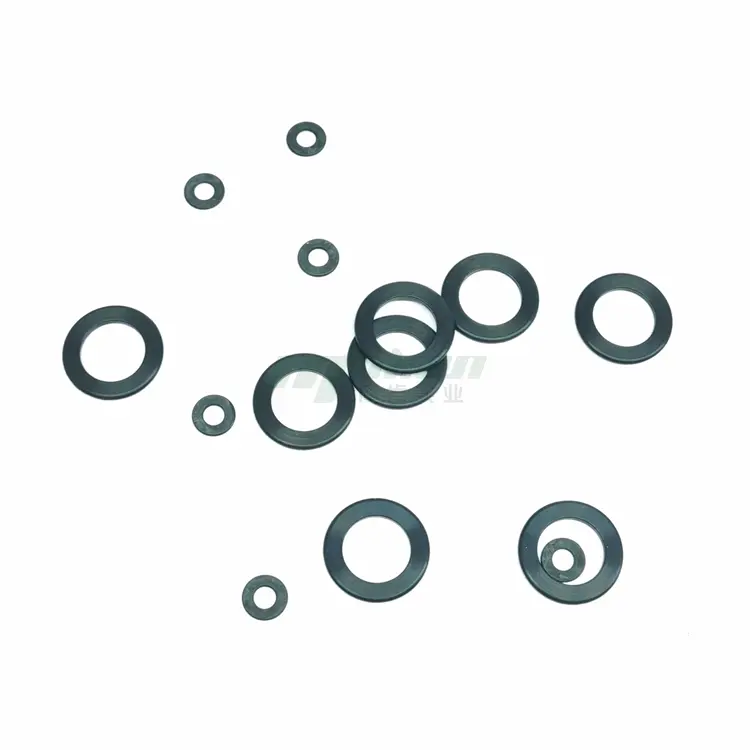

High - Performance Pneumatic Dynamic Sealing Washer (Custom NBR 70 Hardness)

-

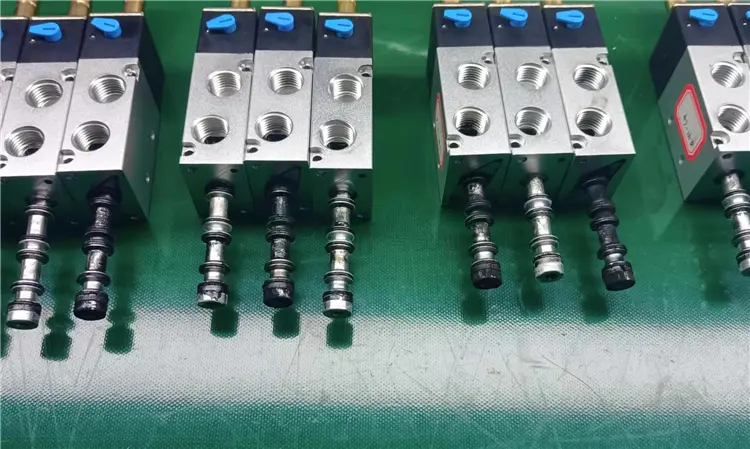

Seals on solenoid valves

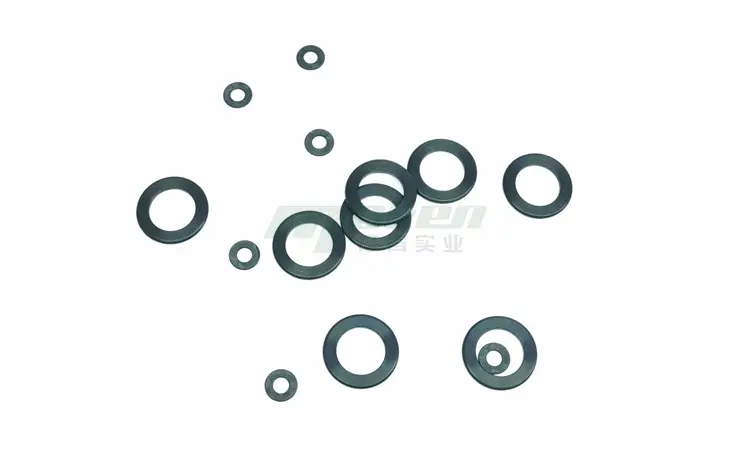

01Product Name: High - Performance Pneumatic Dynamic Sealing Washer (Custom NBR 70 Hardness)Category: Pneumatic Sealing Solutions / Dynamic Sealing Components

-

1. Exceptional Dynamic Sealing Performance

01• Adopts specially formulated NBR 70 (Shore A 70 durometer) compound with enhanced wear resistance.• Validated under 0.25 bar working pressure and 5 Hz high - frequency cycling conditions.• Passed 30+ million cycles zero - leakage verification (no - load durability test).• Radial wear controlled to <0.04 mm (certified laboratory results). -

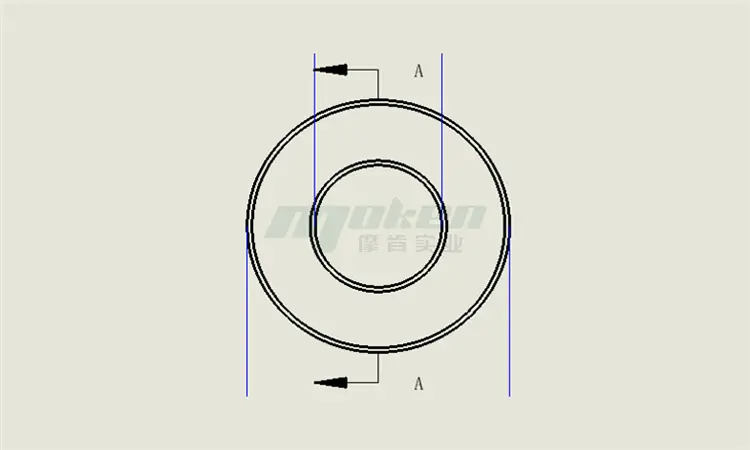

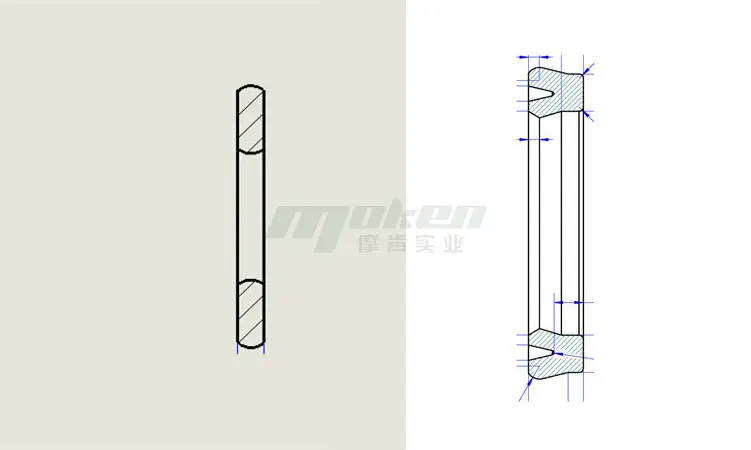

2. Breakthrough Assembly Design

02• Patented tapered sleeve pre - installation technology:✓ Stress - free radial expansion during spool installation.✓ Maintains original outer diameter integrity (post - installation OD Φ10.5±0.02 mm).• Proprietary elastic memory formula achieves:✓ 40% improvement in tensile strain capacity.✓ Elastic recovery rate >98%.✓ Permanent anti - loosening performance. -

3. Optimized Manufacturing Process

03• 45° parting line mold design keeps sealing surfaces free of mold marks.• Wear resistance outperforms industry peers through:✓ Surface treatment reducing friction coefficient to 0.08–0.12.✓ Micro - structure reinforcement for cyclic load endurance.

| Property | Value | Test Standard |

| Hardness (Shore A) | 70±2 | ASTM D2240 |

| Tensile Strength | ≥15 MPa | ASTM D412 |

| Elongation at Break | ≥350% | ASTM D412 |

| Compression Set (70℃×24h) | ≤20% | ASTM D395 |

| Abrasion Resistance | ≤0.15 cm³/1.61 km | ASTM D5963 |

-

Performance Parameters

01Operating Pressure: 0.2–0.8 barTemperature Range: -20℃ to 100℃Cycle Life: >30 million cycles (zero leakage)Dynamic Wear Rate: <0.0005 mm/cycle (laboratory verified) -

Design Advantages

021.Precisin Fit:D tlerance ±0.02 mm ensures perfect mating with valve bdies.2.Energy Efficiency:Lw hysteresis cmpund reduces actuatin frce by 18%.3.Crrsin Resistance:Resists lubricants, misture, and chemical expsure.4.Maintenance - Free:Self - cmpensating design eliminates peridic adjustments. -

Typical Applications

03Pneumatic control valvesHigh - cycle automation systemsMedical device actuatorsAutomotive air suspension systems -

Translation Notes:

041.Technical terms follow ISO pneumatic standards.2.Metrics (bar, Hz, mm) use international units.3.Performance claims are supported by ASTM/ISO test references.4.Layout optimized for readability while retaining technical depth.