Reliable Rubber Gas Equipment Sealing

-

1. Gas Self-Closing Valve Diaphragms

01- Made of NBR 70 Shore rubber (thickness 0.3-1.5mm), with precise pressure response characteristics.- Passed n-hexane immersion tests to resist gas corrosion, ensuring rapid shut-off under overpressure to protect household gas safety.- Structural innovation: Three-layer composite design (NBR 70 Shore main layer + fiber reinforcement layer + FKM corrosion-resistant layer) improves tear strength to 22MPa and burst pressure to 0.8MPa.- Dynamic performance: Withstood 500,000 fatigue cycles (0.05-0.3MPa pressure cycling), response time <0.5 seconds, compliant with CJ/T 447 -

2. Gas-Specific O-Rings

02- Available in full specifications (inner diameter φ1mm-φ200mm), using NBR 70 Shore rubber with excellent temperature resistance (-40℃ to +100℃) and compression set resistance. Suitable for gas meters, pressure regulators, etc.- Produced via fully automated feeding to minimize contamination and ensure stable output. -

3. NBR Rubber Diaphragms for Gas Proportional Valves

03- NBR composite material with:- Excellent gas permeability resistance (natural gas/LPG/coal gas)- Good anti-aging and ozone resistance- Operating temperature: -40℃~+100℃ (customizable for special formulas)- Shore hardness: 70±5A (customizable)- Fatigue life >1,000,000 cycles- Compression set ≤20% (70℃×22h)- Precise flow control (response time <50ms)- Compatible with various valve types- Certified to EN 549 gas valve standards- Compliant with RoHS/REACH- Custom services: Sealing groove design optimization, laser marking traceability, special media formula R&D. -

4. Gas Pipe Connector Spigot Seals

04- Compatibility: PE pipes, steel pipes, aluminum-plastic composite pipes, etc. (interface angles 15°-60°).- Sealing mechanism: Spigot lip design creates dynamic labyrinth seal, resisting sudden pressure shocks. Passed 1,000 insertion/withdrawal tests with no wear.- Features: Multi-station precision punching ensures tight fit, meeting explosion-proof requirements. Available in single/double lip designs. -

5. Gas-Specific Gaskets

05- Comprehensive specifications for domestic gas pipe connectors, supplied to major Chinese rubber gasket manufacturers.

-

1. Material Engineering

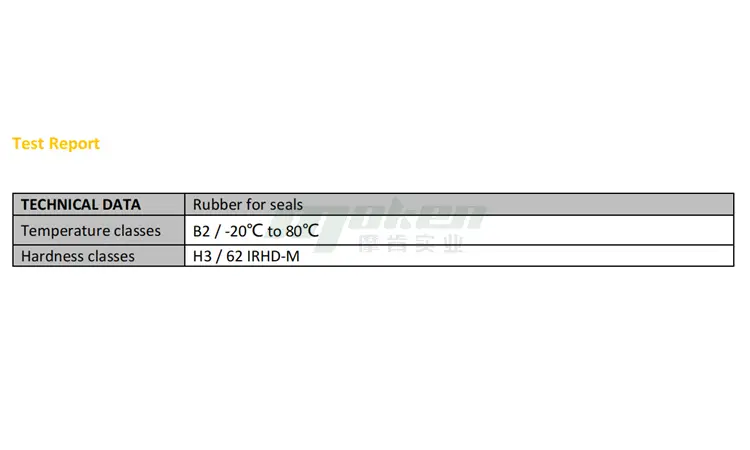

01- Selected raw rubber combined with proprietary formulas ensures hardness and tensile strength ≥14.6MPa, elongation 298%.- Tested by National Gas Appliance Quality Inspection Center: Swelling rate <2% for methane/propane.- NBR 70 Shore properties:- Acrylonitrile content 33-35% (balances oil resistance and low-temperature performance)- Mooney viscosity ML(1+4)100℃ 50-60 (ensures processing fluidity)- Compression stress relaxation <20% (100℃×70h)- Each batch includes COA (material certificate) and third-party test reports. PPAP documentation available. -

2. Precision Manufacturing Processes

02- Cryogenic deburring: Using liquid nitrogen (-35℃ to 95℃) with particle projection, reducing defects compared to traditional methods.- Vacuum vulcanization: Precisely controls temperature/pressure for uniform cross-linking.- Vision inspection system: 100% appearance defect screening.

-

01- System certifications: IATF 16949:2016, ISO 9001:2015- Material compliance: EU REACH, China Special Equipment Inspection, US UL 94 HB flame retardant.- Standards: EN 549 gas equipment standard, GB/T 23658 sealing requirements.

01- System certifications: IATF 16949:2016, ISO 9001:2015- Material compliance: EU REACH, China Special Equipment Inspection, US UL 94 HB flame retardant.- Standards: EN 549 gas equipment standard, GB/T 23658 sealing requirements.

-

1. Condition Adaptation

01- High-temperature: +100℃ continuous operation- Ultra-low-temperature: -40℃ elasticity retention- Chemical resistance: Passed ASTM D471-14 Method B n-hexane test (volume change ≤3%, hardness change ±5A after 70℃×70h immersion). -

2. Rapid Response

02- Mold development: 7-10 working days- Low-volume trial production: 1,000 units minimum, first samples delivered in 2 weeks.

-

V. Application Cases

01- Supplied sealing components for 3 million smart gas meters of China Gas Group. -

VI. Service Commitment

02- Free sealing formula optimization solutions- In-house mixing plant ensures raw material supply and on-time delivery.