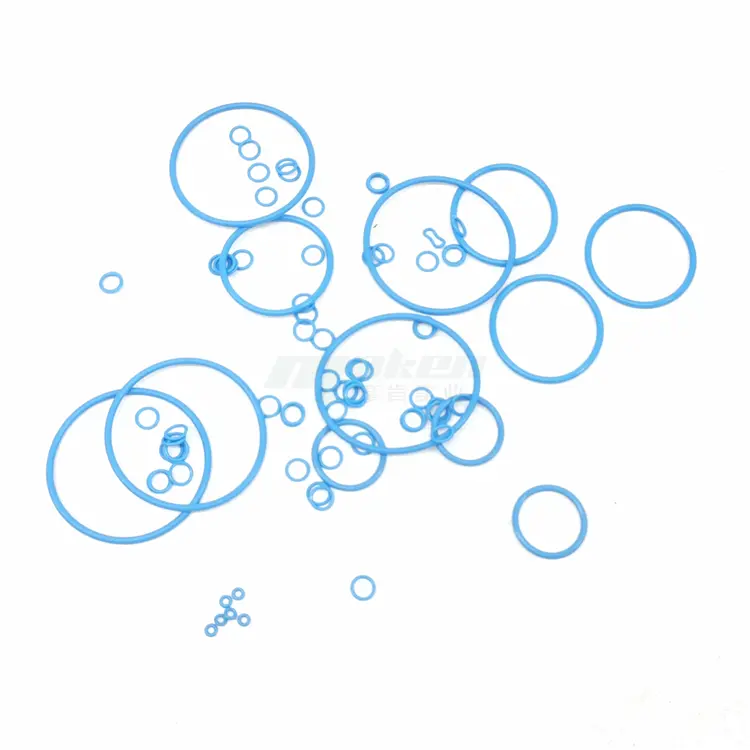

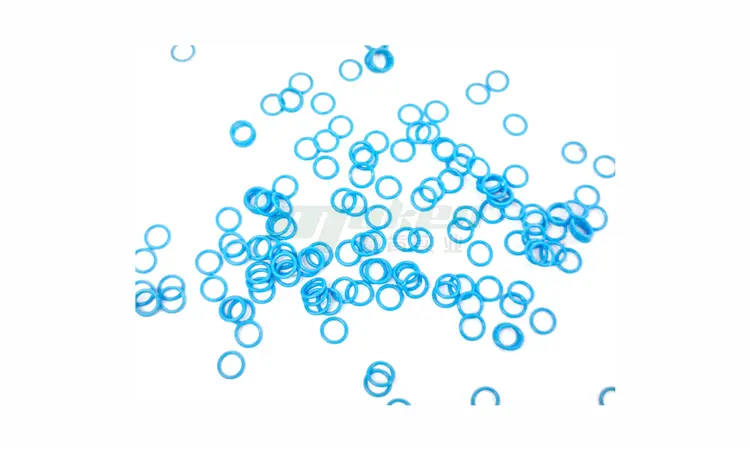

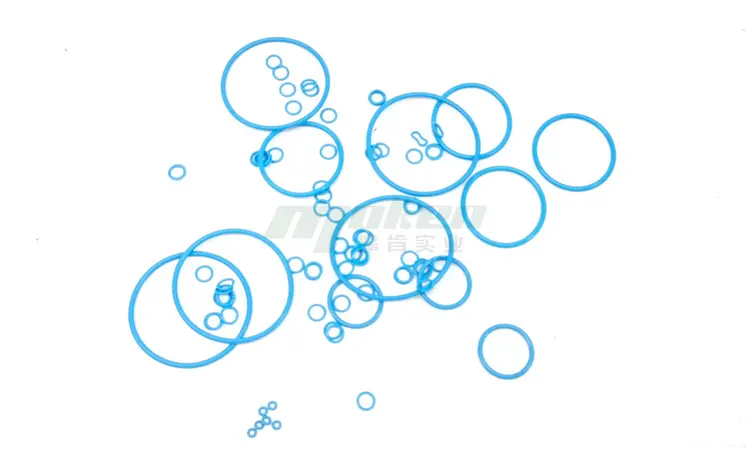

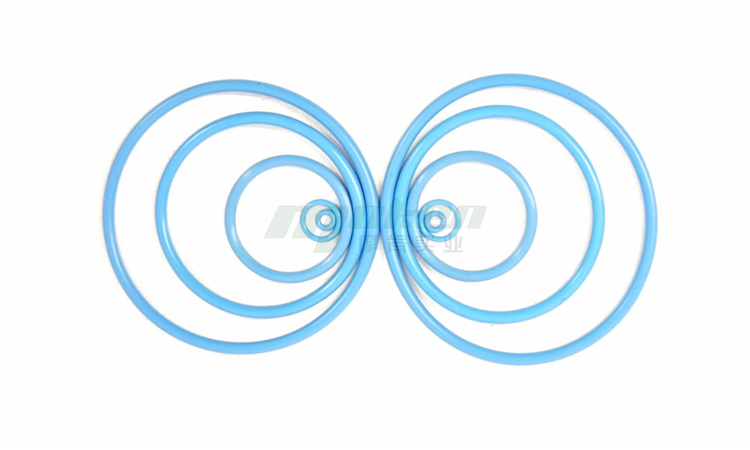

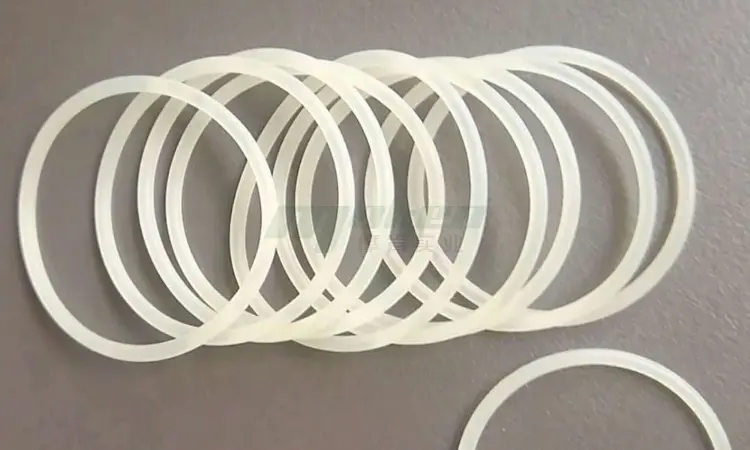

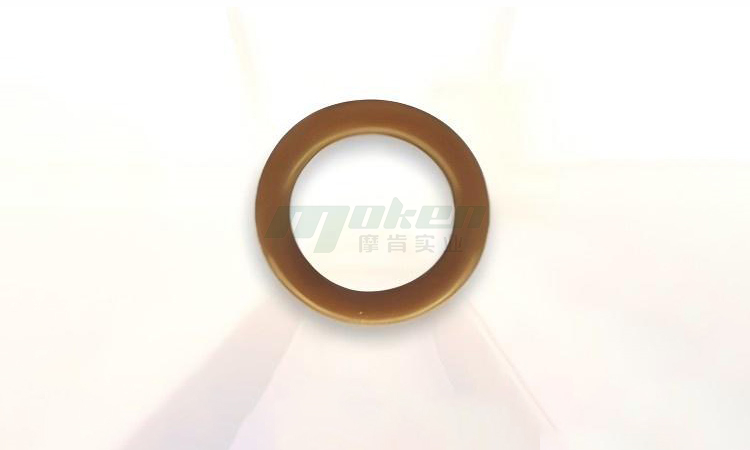

Fluorosilicone and Perfluoroether (FFKM) O-Rings

Applications of Fluorosilicone and Perfluoroether (FFKM) O-rings in the Semiconductor Industry

I. Supplementary Material Properties (More Comprehensive and Authoritative)

-

Excellent Chemical Resistance

01It can resist the erosion of highly corrosive chemical reagents such as hydrofluoric acid and nitric acid, ensuring that the sealing parts will not fail due to corrosion during semiconductor etching, cleaning and other processes. -

Good High-temperature Resistance

02It can be used continuously in the temperature range from -60°C to 200°C. Some models can withstand transient high temperatures, making it suitable for high-temperature processes such as etching and coating. -

High Vacuum Performance

03With a low outgassing rate, it meets the requirements of the high vacuum environment in the semiconductor industry, prevents gas leakage, and maintains the process vacuum degree. -

Superb Aging Resistance

04It can maintain elasticity and sealing performance during long-term use, reducing the problem of frequent replacement of equipment due to the aging of sealing parts. -

Good Electrical Insulation

05It provides reliable electrical insulation at electrical connection parts, prevents short circuits, and ensures the electrical safety of equipment. -

Low Outgassing Rate and Low Particle Generation

06It avoids the contamination of wafer carrying and transmission processes, meeting the requirements of high cleanliness production.

-

Ultra-high Temperature Resistance

01It has a wider temperature resistance range (from -20°C to 320°C or even higher), and can be stably used in extreme high-temperature processes of semiconductor equipment, such as high-temperature oxidation and sintering. -

Super Strong Chemical Resistance

02It is almost completely resistant to all highly corrosive chemical media in the semiconductor industry, including aqua regia, concentrated sulfuric acid, specialty gases, etc., and is suitable for harsh corrosion environments that fluorosilicone cannot handle. -

Extremely Low Gas Permeability

03In an ultra-high vacuum environment, its outgassing rate is much lower than that of fluorosilicone, and the sealing performance is better, meeting the ultimate requirements for vacuum degree of high-end semiconductor equipment. -

04

04Extra-long Service Life

Its aging resistance performance is more excellent. In semiconductor equipment with high-frequency and long-cycle operation, its service life is significantly longer than that of fluorosilicone, reducing the maintenance cost.

II. Supplementary Application Scenarios (Incorporating FFKM)

-

Fluorosilicone

01It is used for the sealing of doors and observation windows of chambers in processes such as etching and coating, and can withstand conventional high temperatures and corrosive gases. -

Perfluoroether (FFKM)

02For chambers involving extreme corrosion or high-temperature environments such as aqua regia cleaning and high-temperature sintering, such as high-end etching equipment and special material coating equipment, it ensures the sealing stability.

-

Fluorosilicone

01It seals pipelines and valves for transporting common corrosive gases and chemical reagents, preventing leakage and cross-contamination. -

Perfluoroether (FFKM)

02It is used for pipelines and valves transporting concentrated sulfuric acid and specialty corrosive gases (such as chlorine trifluoride), dealing with strong corrosive media that fluorosilicone cannot withstand, and ensuring the safety of the transmission system.

-

Fluorosilicone

01It is used for the sealing of conventional wafer carriers and transfer tracks, isolating dust and particle contamination. -

Perfluoroether (FFKM)

02In advanced manufacturing processes with extremely high requirements for cleanliness and chemical resistance (such as wafer production below 5nm), it seals key transmission components to avoid any minor contamination affecting the wafer quality.

-

Fluorosilicone

01It meets the sealing requirements of common vacuum pumps under high temperature and pressure changes, ensuring the pumping efficiency. -

Perfluoroether (FFKM)

02It is suitable for high-end vacuum pumps. In an ultra-high vacuum environment and when in contact with highly corrosive pumping media, it maintains the sealing performance and improves the stability of the equipment.

-

Fluorosilicone

01It provides insulation and sealing protection for conventional electrical connectors and sockets. -

Perfluoroether (FFKM)

02It is used for electrical connection parts in semiconductor equipment with extremely high requirements for high-temperature and chemical corrosion resistance, such as special power supply interfaces, ensuring electrical safety in extreme environments.

-

Perfluoroether (FFKM)

01In special process equipment in the semiconductor industry, such as advanced packaging and ion implantation, it deals with complex environments of high temperature and high corrosion, seals core components such as reaction chambers and gas distribution systems, and ensures the process accuracy.