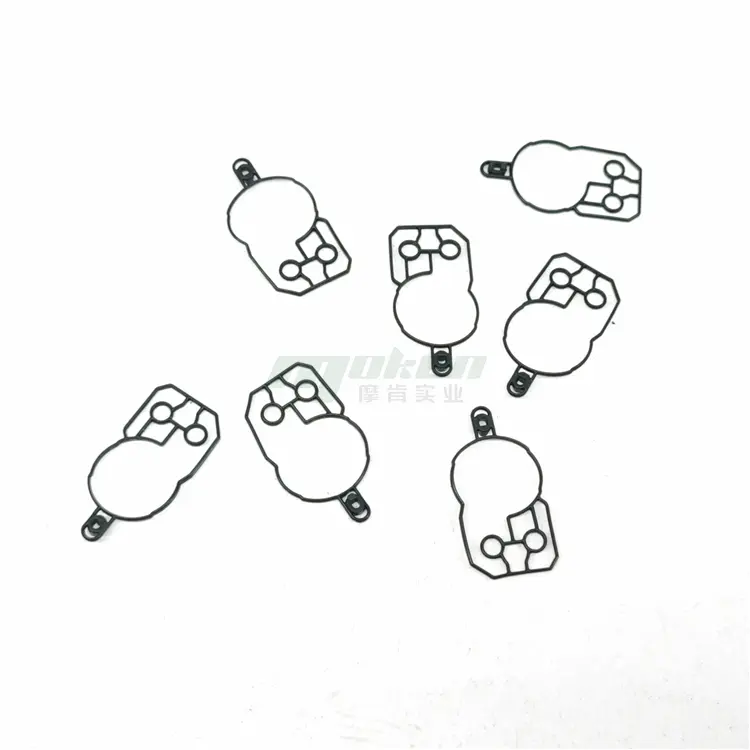

Chemical Resistant FKM Sealing Rings High - Temperature Resistant

-

011. Physical and Mechanical Properties: FKM sealing rings exhibit relatively high tensile strength and hardness, which enables them to maintain structural integrity and resist deformation when subjected to a certain external force. However, relatively speaking, their elastic performance is somewhat inferior. In some application scenarios with extremely high requirements for elasticity, it may be necessary to combine other materials or designs to meet the requirements.2. High Temperature Resistance: Among various rubber materials, the high temperature resistance of FKM fluororubber is truly remarkable. It can operate stably for a long time in a high-temperature environment of 250°C. Even when exposed to an extremely high temperature of 320°C for a short period, it can still maintain its basic properties without significant performance degradation. This characteristic makes it an ideal choice for sensor seals in the high-temperature areas of automotive engines.

011. Physical and Mechanical Properties: FKM sealing rings exhibit relatively high tensile strength and hardness, which enables them to maintain structural integrity and resist deformation when subjected to a certain external force. However, relatively speaking, their elastic performance is somewhat inferior. In some application scenarios with extremely high requirements for elasticity, it may be necessary to combine other materials or designs to meet the requirements.2. High Temperature Resistance: Among various rubber materials, the high temperature resistance of FKM fluororubber is truly remarkable. It can operate stably for a long time in a high-temperature environment of 250°C. Even when exposed to an extremely high temperature of 320°C for a short period, it can still maintain its basic properties without significant performance degradation. This characteristic makes it an ideal choice for sensor seals in the high-temperature areas of automotive engines. -

023. Oil Resistance: FKM has an extremely strong tolerance to various oils. Whether it is the lubricating oil, fuel oil in the automotive engine, or other industrial oils, it is difficult to cause corrosion or swelling to it. It can effectively prevent oil leakage and ensure the normal operating environment of the sensor.4. Resistance to Chemicals and Corrosive Media: The resistance of FKM to chemicals and corrosive media is also outstanding and can be regarded as one of the best among rubber materials. It can even withstand the strong corrosiveness of aqua regia (a mixture composed of concentrated hydrochloric acid (HCl) and concentrated nitric acid (HNO₃) in a volume ratio of 3:1). In complex chemical environments, it provides reliable protection for automotive sensors.

023. Oil Resistance: FKM has an extremely strong tolerance to various oils. Whether it is the lubricating oil, fuel oil in the automotive engine, or other industrial oils, it is difficult to cause corrosion or swelling to it. It can effectively prevent oil leakage and ensure the normal operating environment of the sensor.4. Resistance to Chemicals and Corrosive Media: The resistance of FKM to chemicals and corrosive media is also outstanding and can be regarded as one of the best among rubber materials. It can even withstand the strong corrosiveness of aqua regia (a mixture composed of concentrated hydrochloric acid (HCl) and concentrated nitric acid (HNO₃) in a volume ratio of 3:1). In complex chemical environments, it provides reliable protection for automotive sensors. -

035. Flame Retardancy: FKM has good flame retardancy and belongs to self-extinguishing rubber when removed from the fire source. In the possible fire risk scenarios of automobiles, it can effectively prevent the spread of fire and provide additional safety protection for sensors and surrounding equipment.6. Weather Resistance and Ozone Resistance: FKM has excellent tolerance to harsh weather conditions and high-concentration ozone environments. After being exposed outdoors or in an ozone environment for a long time, its performance will not decline significantly, and it can maintain good sealing performance.

035. Flame Retardancy: FKM has good flame retardancy and belongs to self-extinguishing rubber when removed from the fire source. In the possible fire risk scenarios of automobiles, it can effectively prevent the spread of fire and provide additional safety protection for sensors and surrounding equipment.6. Weather Resistance and Ozone Resistance: FKM has excellent tolerance to harsh weather conditions and high-concentration ozone environments. After being exposed outdoors or in an ozone environment for a long time, its performance will not decline significantly, and it can maintain good sealing performance. -

047. Limitations: FKM also has some disadvantages. Its low-temperature resistance is poor, and it is likely to become hard and brittle in a low-temperature environment, resulting in a decrease in sealing performance. Its elasticity is insufficient, and its performance is not ideal in some applications that require frequent expansion and contraction. Its tolerance to polar substances such as water is poor, and it may be affected in a humid environment. It has a high processing difficulty and a relatively high production cost, resulting in a relatively expensive price.

047. Limitations: FKM also has some disadvantages. Its low-temperature resistance is poor, and it is likely to become hard and brittle in a low-temperature environment, resulting in a decrease in sealing performance. Its elasticity is insufficient, and its performance is not ideal in some applications that require frequent expansion and contraction. Its tolerance to polar substances such as water is poor, and it may be affected in a humid environment. It has a high processing difficulty and a relatively high production cost, resulting in a relatively expensive price.

-

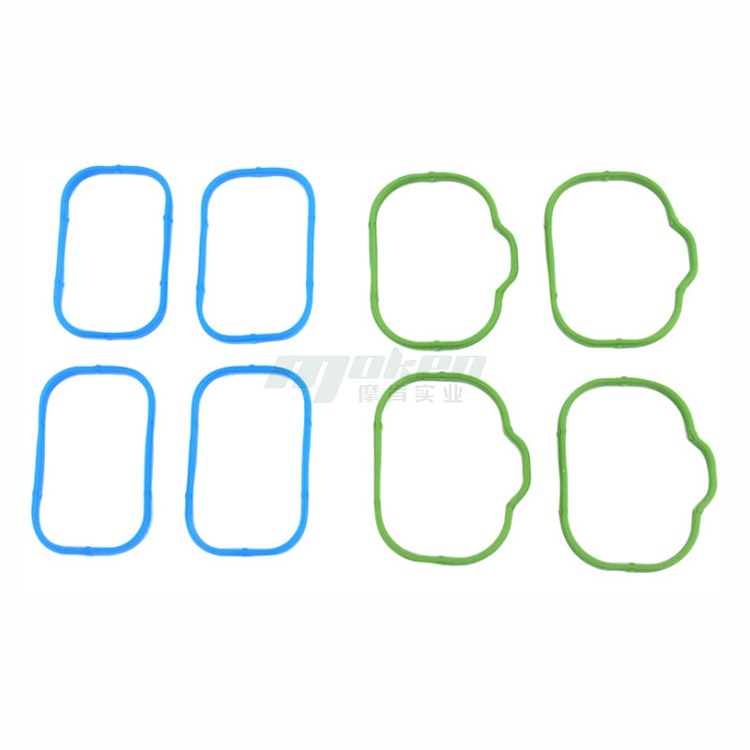

011. Refrigerant Resistance: HNBR has a good tolerance to various refrigerants used in automotive air conditioning systems. It will not react chemically with the refrigerants, effectively avoiding the damage and performance degradation of the seals caused by the erosion of the refrigerants, and ensuring the stable operation of automotive air conditioning sensors.2. Chemical Resistance: It can resist the erosion of a variety of chemical substances. Whether it is acidic, alkaline, or other corrosive chemical substances, it is difficult to cause damage to it, providing reliable protection for sensors in complex chemical environments.3. Heat Resistance: In a high-temperature environment, HNBR can maintain stable performance and can withstand relatively high temperatures, meeting the usage requirements of sensor seals in high-temperature areas such as the automotive engine compartment.

011. Refrigerant Resistance: HNBR has a good tolerance to various refrigerants used in automotive air conditioning systems. It will not react chemically with the refrigerants, effectively avoiding the damage and performance degradation of the seals caused by the erosion of the refrigerants, and ensuring the stable operation of automotive air conditioning sensors.2. Chemical Resistance: It can resist the erosion of a variety of chemical substances. Whether it is acidic, alkaline, or other corrosive chemical substances, it is difficult to cause damage to it, providing reliable protection for sensors in complex chemical environments.3. Heat Resistance: In a high-temperature environment, HNBR can maintain stable performance and can withstand relatively high temperatures, meeting the usage requirements of sensor seals in high-temperature areas such as the automotive engine compartment. -

024. Ozone Resistance: In a high-concentration ozone environment, HNBR is not easily oxidized and can maintain its physical and chemical properties for a long time, ensuring the service life of the seals.5. Aging Resistance: Even after long-term use and the influence of various environmental factors, the performance degradation of HNBR is very slow. It has excellent aging resistance, which can reduce the replacement frequency of seals and lower maintenance costs.6. Broad Temperature Range Adaptability: The operating temperature range of HNBR is from -40°C to 160°C. It can not only maintain good flexibility and sealing performance in cold winter but also work stably in hot summer and high-temperature working conditions, adapting to the needs of automobiles in different climate conditions and working environments.

024. Ozone Resistance: In a high-concentration ozone environment, HNBR is not easily oxidized and can maintain its physical and chemical properties for a long time, ensuring the service life of the seals.5. Aging Resistance: Even after long-term use and the influence of various environmental factors, the performance degradation of HNBR is very slow. It has excellent aging resistance, which can reduce the replacement frequency of seals and lower maintenance costs.6. Broad Temperature Range Adaptability: The operating temperature range of HNBR is from -40°C to 160°C. It can not only maintain good flexibility and sealing performance in cold winter but also work stably in hot summer and high-temperature working conditions, adapting to the needs of automobiles in different climate conditions and working environments. -

037. Resistance to Extreme Environments: In addition to its excellent high and low-temperature resistance, HNBR can also withstand extreme environments such as high temperature and pressure, low temperature, oil resistance, and high and low-temperature cycling. In the automotive engine, when it is subjected to frequent temperature changes caused by frequent starting and stopping, as well as high-pressure working environments, it can still maintain stable performance.8. Strong Corrosion Resistance: For some highly corrosive media, HNBR also has good tolerance, effectively protecting sensors from corrosion.9. Dynamic Pressure Resistance: When subjected to dynamic pressure, HNBR can maintain good sealing performance and will not cause sealing failure due to changes in pressure. It is suitable for the sealing of sensors under dynamic working conditions such as vibration and impact during the driving process of automobiles.

037. Resistance to Extreme Environments: In addition to its excellent high and low-temperature resistance, HNBR can also withstand extreme environments such as high temperature and pressure, low temperature, oil resistance, and high and low-temperature cycling. In the automotive engine, when it is subjected to frequent temperature changes caused by frequent starting and stopping, as well as high-pressure working environments, it can still maintain stable performance.8. Strong Corrosion Resistance: For some highly corrosive media, HNBR also has good tolerance, effectively protecting sensors from corrosion.9. Dynamic Pressure Resistance: When subjected to dynamic pressure, HNBR can maintain good sealing performance and will not cause sealing failure due to changes in pressure. It is suitable for the sealing of sensors under dynamic working conditions such as vibration and impact during the driving process of automobiles. -

0410. High Wear Resistance: HNBR has high wear resistance. During long-term use, even when subjected to friction and other effects, it can still maintain good physical form and performance, extending the service life of the seals.In conclusion, FKM and HNBR play important roles in the field of automotive sensor seals with their unique performance advantages. Our company will reasonably select these two materials according to different application scenarios and requirements, providing the most suitable sealing solutions for automotive sensors to meet the strict requirements of the automotive industry for high-performance and highly reliable sensors.

0410. High Wear Resistance: HNBR has high wear resistance. During long-term use, even when subjected to friction and other effects, it can still maintain good physical form and performance, extending the service life of the seals.In conclusion, FKM and HNBR play important roles in the field of automotive sensor seals with their unique performance advantages. Our company will reasonably select these two materials according to different application scenarios and requirements, providing the most suitable sealing solutions for automotive sensors to meet the strict requirements of the automotive industry for high-performance and highly reliable sensors.