EPDM + FKM + HNBR + NBR + FLS + SI + FFKM + PTFE

EPDM peroxide material is a cross - linked elastomer formed by introducing a small amount of third monomers with double bonds (such as ENB) into the main chain of ethylene - propylene copolymer and through the peroxide vulcanization system. Its saturated main chain structure endows it with excellent heat resistance (from - 55°C to 150°C), weather resistance, ozone resistance and chemical stability, especially showing outstanding performance in complex media such as chloramine - containing drinking water and ethylene glycol coolant.

This material has passed a number of international authoritative certifications, including AS NZS4020 in Australia/New Zealand, JFSL 370/JIS S3200 - 7 in Japan, KIWA in the Netherlands, KTW - BWGL/UBA - LL/W270/W534/DVGW in Germany, NSF61 in the USA, Ö - NORM/LMG in Austria, WRAS/WRC in the UK, EN681 - 1 in Europe, PAH (Polycyclic Aromatic Hydrocarbons) related certifications, ACS in France. It meets the strict global standards for drinking water contact, industrial sealing, sanitary equipment, etc.

Compared with traditional sulfur - vulcanized EPDM, the EPDM peroxide material achieves higher tensile strength, lower compression set and chloramine - resistant performance that complies with the standards of many countries through a uniform cross - linked network. Its advantages such as resistance to chemical media erosion, high - temperature steam resistance (with a short - term peak of 180°C) and gas impermeability make it widely used in industrial steam pipeline sealing, pipeline sealing for medical gases, solar energy, oil and natural gas, high - end bathrooms, new energy vehicle battery cooling systems and automotive turbocharger components, etc., providing long - term sealing solutions for harsh environments.

A copolymer of ethylene and propylene with a saturated backbone, EPDM exhibits excellent heat, aging, ozone, and chemical stability but cannot be sulfur-vulcanized. Sulfur vulcanization becomes possible with a third monomer containing double bonds (EPDM). Operating temperature: -45~100℃. Resistant to polar solvents (e.g., alcohols, ketones, glycols, phosphate esters). Advantages: weather/ozone/water resistance, high-temperature steam tolerance, good gas impermeability. Disadvantages: unsuitable for food contact or aromatic hydrocarbon exposure. Applications include high-temperature steam seals,Bathroom, braking systems, and radiator gaskets.

Produced by hydrogenating nitrile rubber to reduce double bonds, HNBR offers superior heat and weather resistance compared to NBR. Operating temperature: -40~160℃. Oil resistance is similar to NBR, with better abrasion resistance, corrosion resistance, tensile/tear strength, and compression set. Resistant to ozone and sunlight. Suitable for detergent environments (e.g., laundry/dishwashing). Disadvantages: incompatible with alcohols, esters, or aromatic solutions. Used in R134a refrigerant seals and automotive engine systems.

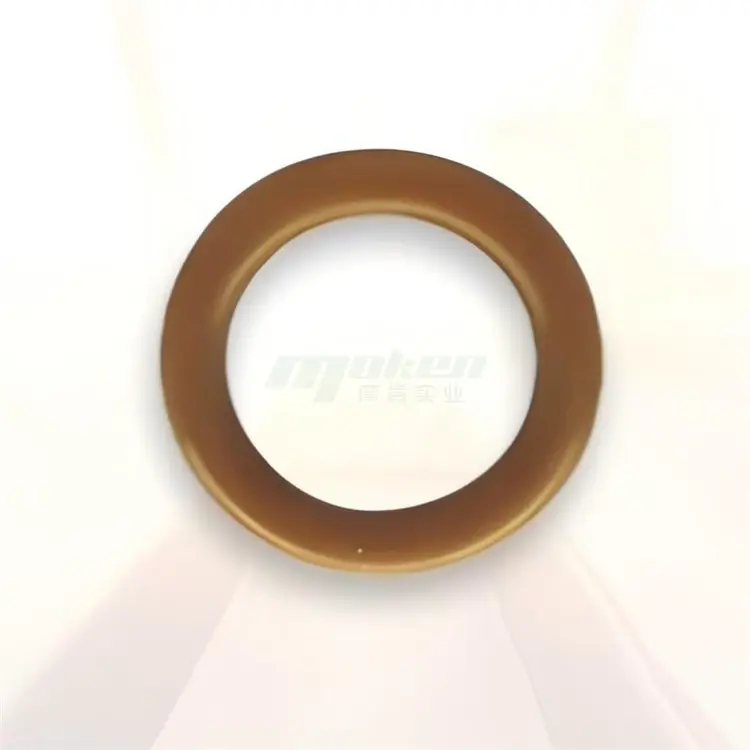

FKM contains fluorine in its polymer structure, with types defined by fluorine content. The 6-fluorinated variety (e.g., DuPont’s "Viton") offers superior heat resistance over silicone rubber, along with excellent chemical, oil (except ketones/esters), weather, and ozone resistance. Poor low-temperature flexibility. Standard operating temperature: -20~250℃ (special grades down to -40℃). Resists most oils, solvents, acids, aliphatic/aromatic hydrocarbons, and animal/vegetable oils. Disadvantages: incompatible with ketones, low-molecular-weight esters, and nitrate mixtures. Used in automotive fuel systems, diesel engines, and chemical plant seals.

A copolymer of acrylonitrile and butadiene (acrylonitrile content: 18%~50%). Higher acrylonitrile content improves resistance to petroleum oils and hydrocarbons but reduces low-temperature flexibility. Operating temperature: -50~100℃. Commonly used in oil seals and O-rings. Advantages: oil/water/solvent resistance, good compression set, abrasion, and elongation. Disadvantages: incompatible with polar solvents (e.g., ketones, ozone, nitrohydrocarbons, MEK, chloroform). Widely used in fuel/lubricant tanks and rubber parts exposed to petroleum-based hydraulic oils, gasoline, water, silicone grease, esters, and glycols.

With a silicon-oxygen backbone (-Si-O-Si-), SI features excellent heat, cold, ozone, and atmospheric aging resistance, plus high electrical insulation. However, it has low tensile strength and poor oil resistance. Modified formulations can achieve 1500 PSI tensile strength, 88 LBS tear resistance, and good elasticity/compression. Resistant to neutral solvents, thermal extremes, and ozone/oxidation. Disadvantages: incompatible with concentrated solvents, oils, acids, and diluted NaOH. Used in household appliances (kettles, irons, microwaves), electronics (phone keys, DVD pads), and human-contact products (water dispensers).

Fluorinated silicone rubber combines the benefits of fluoroelastomers and silicone rubber. It resists oils, solvents, fuels, and extreme temperatures (-55~250℃). Suitable for environments with oxygenated chemicals, aromatics, and chlorinated solvents. Avoid exposure to brake fluid, ketones, and hydrazine. Applications include aerospace components, semiconductors, chemical cleaning equipment, and medical/aviation seals.

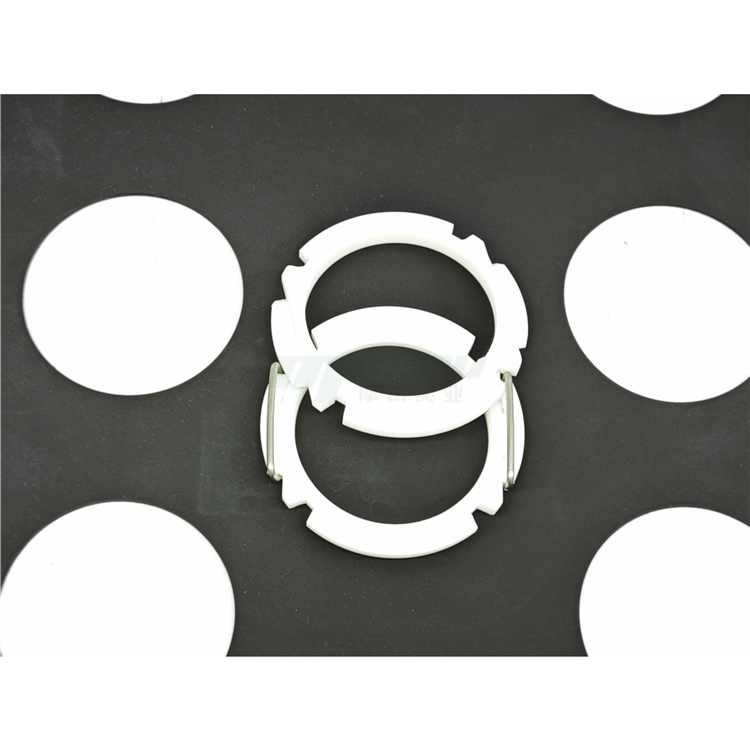

PTFE (polytetrafluoroethylene) is a kind of polymer material. In its molecular structure, carbon atoms form stable covalent bonds with fluorine atoms, and it has a highly symmetrical linear structure. This structure endows it with excellent properties such as chemical stability, corrosion resistance and a low coefficient of friction. PTFE is widely used in anti-corrosion equipment for construction machinery, oil cylinders, chemical pipelines, reaction kettles, etc. It is also used to make the coating of non-stick pans, which can prevent food from sticking to the pan and make it easy to clean. It can also be used as a coating sprayed on the surface of rubber sealing rings during the manufacturing process to facilitate automatic assembly. In the field of wires and cables, PTFE can be used as an insulating material to improve the electrical performance and weather resistance of the cables.

Offers maximum heat resistance, excellent chemical resistance, low outgassing, and plasma resistance. Disadvantages: poor low-temperature flexibility, high cost, and complex manufacturing. Used in semiconductors, thin-film processes (PVC, CVD, etching), and high-vacuum seals.