Drinking Water Sealing Scenarios and Rubber Sealing Parts

-

A. Ethylene Propylene Diene Monomer (EPDM)

01EPDM is divided into sulfur-cured EPDM and peroxide-cured EPDM. It has strong chemical stability, good tolerance to water, water vapor, acids, and alkalis, and can be used in humid environments for a long time. It is non-toxic and odorless, meets the drinking water hygiene standards, is not easy to age, and has a long service life. It can be used for the sealing of multi-stage filtration systems in central water purifiers (pressure range: 0-1.6MPa), terminal water purifiers, and the sealing of pipeline interfaces with a diameter of DN300 or more in municipal pipe networks (leakage rate < 0.01L/min), as well as for the sealing gaskets of equipment and the sealing of water pipe connections.For the peroxide vulcanization system (Peroxide EPDM), the crosslink density of the molecular chain reaches 85-90%, which is higher than that of traditional sulfur-cured EPDM (crosslink density: 60-70%). Its tensile strength is increased by 30%, the compression set is reduced by 40%, and the temperature resistance range is expanded to -50°C to 150°C. -

Certification Matrix of Peroxide EPDM:

021. AS/NZS 4020 in Australia/New Zealand: Certification for the safety of materials in contact with water.2. JFSL 370 in Japan: Certification by the Japanese Food Sanitation Association (applicable to food contact materials). JIS S3200-7: Japanese Industrial Standard, aimed at the safety of rubber sealing parts in contact with drinking water.3. KIWA in the Netherlands: Certification by the Dutch Institute for Water and Environment, covering the safety of drinking water equipment and materials.4. KTW/W270 in Germany: Hygiene certification of drinking water contact materials by the German Federal Environment Agency (UBA) (including the W270 standard).DVGW: Certification by the German Gas and Water Industry Association, related to the safety of pipeline systems and materials.KTW-BWGL/UBA-LL: Supplementary certification of German drinking water regulations (for low leakage rate requirements). -

035. NSF/ANSI 61 in the United States: Certification by the National Sanitation Foundation to ensure the safety of materials in contact with drinking water.6. Ö-NORM/LMG in Austria: Austrian standards, aimed at the hygiene requirements of drinking water equipment and materials.7. WRAS/WRC in the UK: Certification by the Water Research Centre in the UK, applicable to the safety of materials in the water supply system.8. EU/InternationalEN 681-1: Standard of the European Committee for Standardization, specifying the material requirements for rubber sealing parts in contact with drinking water.PAK/PAH: German Polycyclic Aromatic Hydrocarbons (PAH) regulations (environmental protection requirements).ACS: French hygiene certification (for products in contact with drinking water).

035. NSF/ANSI 61 in the United States: Certification by the National Sanitation Foundation to ensure the safety of materials in contact with drinking water.6. Ö-NORM/LMG in Austria: Austrian standards, aimed at the hygiene requirements of drinking water equipment and materials.7. WRAS/WRC in the UK: Certification by the Water Research Centre in the UK, applicable to the safety of materials in the water supply system.8. EU/InternationalEN 681-1: Standard of the European Committee for Standardization, specifying the material requirements for rubber sealing parts in contact with drinking water.PAK/PAH: German Polycyclic Aromatic Hydrocarbons (PAH) regulations (environmental protection requirements).ACS: French hygiene certification (for products in contact with drinking water). -

Summary of Certification Coverage:

04- Drinking Water Safety: AS/NZS 4020, JIS S3200-7, KTW/W270, NSF 61, WRAS, EN 681-1, ACS.- Food Contact Safety: JFSL 370, KTW-BWGL (partially).- Environmental Protection and Low Toxicity: PAK/PAH, UBA-LL.- Industry Standards: KIWA, DVGW, Ö-NORM. -

B. Vinyl Methyl Silicone Rubber (VMQ)

05Performance Advantages: The Shore hardness can be selected from 20-80A, the elongation at break is > 400%, the continuous working life at a high temperature of 180°C is > 5 years, and the biocompatibility reaches ISO 10993-5 level. It has outstanding heat resistance and cold resistance, and can maintain good elasticity within the temperature range of -60°C to 250°C. It has excellent physiological inertia, will not chemically react with drinking water, is safe and non-toxic, and is often used in key parts in direct contact with drinking water, such as the sealing of the valve core of direct drinking water faucets (the number of opening and closing times > 500,000 times), the aseptic isolation of medical water production equipment (in line with the USP Class VI standard), and the sealing parts inside water dispensers.

-

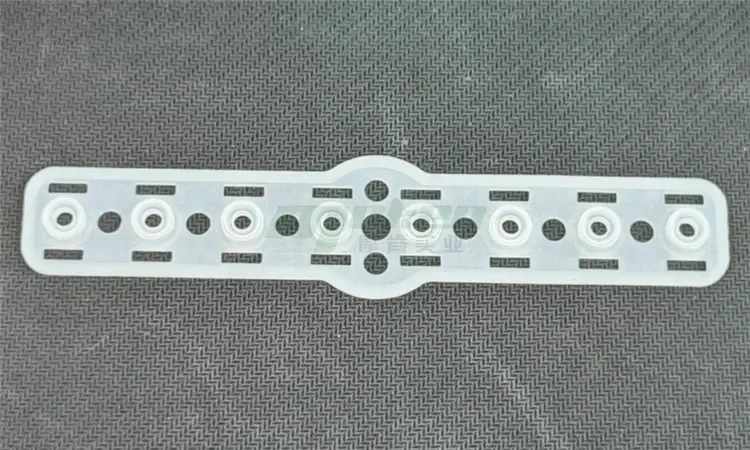

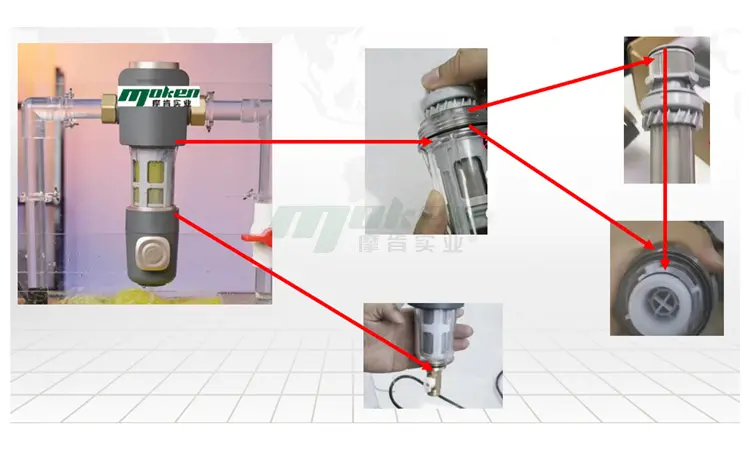

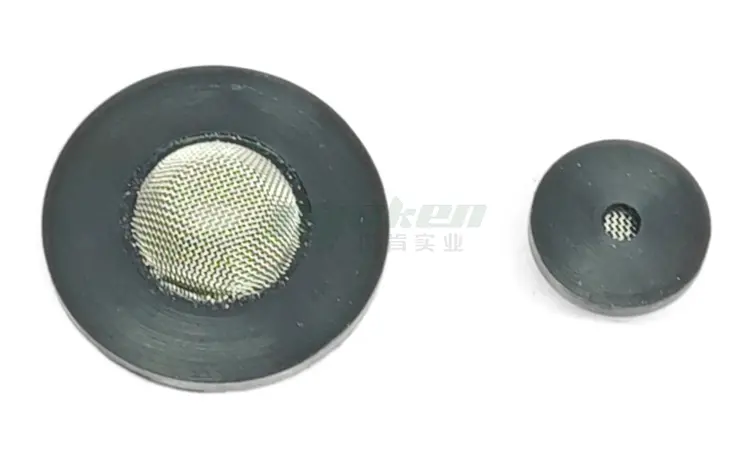

1. Whole-house Water Pipeline for Domestic Drinking Water

01a. Basic StructureTap water flows through the water meter (for metering), the main valve (system switch), and the pre-filter (to intercept sediment and rust) in sequence, forming a basic protection system.b. Central Water PurifierIt is usually installed in the kitchen, living room, or equipment room. Its function is to further remove harmful substances such as residual chlorine, organic matter, and some heavy metals in the water to improve the water quality. Its sealing design ensures the water treatment process, prevents the bypass leakage of untreated water, and ensures the effective removal of pollutants such as residual chlorine and heavy metals. The peroxide EPDM diaphragm valve disc (with a thickness of 1.5mm) controls the backwash cycle, and the flow accuracy is ±5%. -

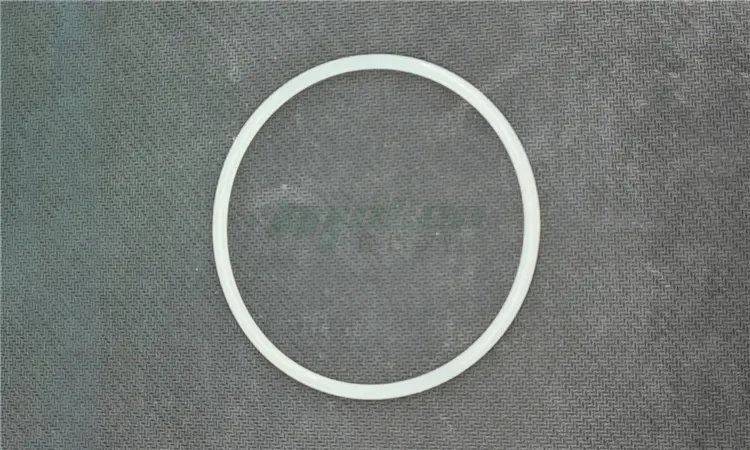

02c. Terminal Direct Drinking Water SystemThe terminal water purifier is generally installed under the kitchen sink. It deeply purifies the water to make it reach the standard for direct drinking. The connection between the terminal water purifier and the direct drinking water faucet needs to be precisely sealed to avoid water leakage and external pollution, and to ensure that the effluent water quality reaches the direct drinking standard. The VMQ O-ring (with a cross-sectional diameter of 3.5mm) seals the reverse osmosis membrane housing to ensure that the salt rejection rate > 99%.d. Water SoftenerThe water softener is applied in both the kitchen and the bathroom. Its main function is to remove calcium and magnesium ions in the water, reduce the water hardness, make the water softer, and is beneficial to the skin and clothes. During the operation of the water softener, operations such as ion exchange are required, and the internal pipeline connections, valves, and other parts all need reliable sealing to ensure the normal operation of the water softener and the stability of the water quality. If the sealing is not good, problems such as brine leakage or unqualified soft water hardness may occur.

02c. Terminal Direct Drinking Water SystemThe terminal water purifier is generally installed under the kitchen sink. It deeply purifies the water to make it reach the standard for direct drinking. The connection between the terminal water purifier and the direct drinking water faucet needs to be precisely sealed to avoid water leakage and external pollution, and to ensure that the effluent water quality reaches the direct drinking standard. The VMQ O-ring (with a cross-sectional diameter of 3.5mm) seals the reverse osmosis membrane housing to ensure that the salt rejection rate > 99%.d. Water SoftenerThe water softener is applied in both the kitchen and the bathroom. Its main function is to remove calcium and magnesium ions in the water, reduce the water hardness, make the water softer, and is beneficial to the skin and clothes. During the operation of the water softener, operations such as ion exchange are required, and the internal pipeline connections, valves, and other parts all need reliable sealing to ensure the normal operation of the water softener and the stability of the water quality. If the sealing is not good, problems such as brine leakage or unqualified soft water hardness may occur. -

2. Industrial Applications

03Ship EngineeringEPDM rubber sealing parts are used in the seawater desalination system, with a chlorine ion resistance concentration > 20,000ppm. EPDM sealing parts are not only resistant to seawater corrosion but also can adapt to the vibration and temperature changes of the ship under different navigation conditions, ensuring the tightness of the pipeline system and preventing liquid leakage and equipment damage.Ocean EngineeringOn offshore platforms, various equipment and facilities are in a harsh marine environment for a long time. EPDM sealing parts can be used for the pipeline connections, equipment sealing, and other parts on the platform to resist the erosion of seawater, sea breeze, salt spray, etc., and ensure the normal operation of the offshore platform and the safety of the staff. -

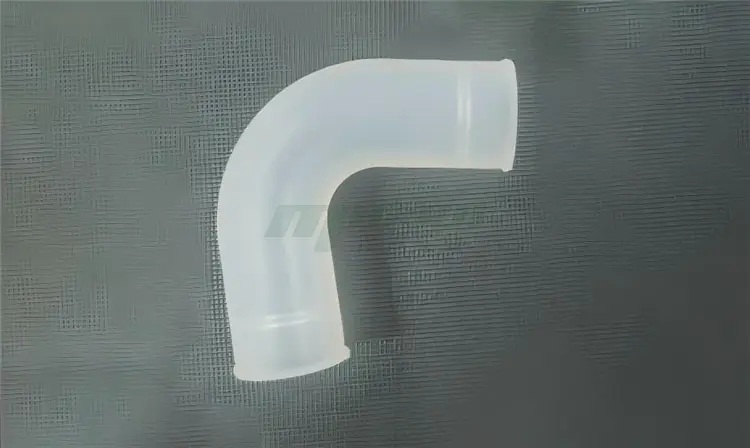

04Building Water Supply and Drainage SystemIn the water supply and drainage pipelines of large buildings, EPDM sealing parts are commonly used in pipeline connection parts such as elbows, tees, and flanges. It can effectively prevent pipeline water leakage and ensure the stable water supply and drainage inside the building. For example, in commercial complexes, office buildings, and other buildings, a large number of water supply and drainage pipeline systems require reliable sealing. EPDM sealing parts can work stably for a long time due to their good water resistance and aging resistance. Moreover, in some underground water supply and drainage pipelines, EPDM sealing parts can resist the erosion of moisture, microorganisms, and chemical substances in the soil, ensuring the tightness and service life of the pipeline system.

04Building Water Supply and Drainage SystemIn the water supply and drainage pipelines of large buildings, EPDM sealing parts are commonly used in pipeline connection parts such as elbows, tees, and flanges. It can effectively prevent pipeline water leakage and ensure the stable water supply and drainage inside the building. For example, in commercial complexes, office buildings, and other buildings, a large number of water supply and drainage pipeline systems require reliable sealing. EPDM sealing parts can work stably for a long time due to their good water resistance and aging resistance. Moreover, in some underground water supply and drainage pipelines, EPDM sealing parts can resist the erosion of moisture, microorganisms, and chemical substances in the soil, ensuring the tightness and service life of the pipeline system. -

05Municipal Pipe NetworkThe EPDM wedge-shaped sealing ring (with a compression force of 15-20N/mm) is used for the interface of DN1200 ductile iron pipes, which has passed the ISO 2531 K9 level pressure test. In the entire process of water intake from the water source, purification treatment, and water distribution in urban waterworks, EPDM sealing parts are applied to various equipment and pipelines. For example, in the sealing parts of equipment such as water pumps, valves, and water storage tanks, it can prevent water leakage and the entry of external impurities, ensuring the safety and stability of urban water supply. In the urban water supply network, EPDM sealing parts are used to connect pipelines of different diameters to ensure the tightness of the network and reduce the waste of water resources.

05Municipal Pipe NetworkThe EPDM wedge-shaped sealing ring (with a compression force of 15-20N/mm) is used for the interface of DN1200 ductile iron pipes, which has passed the ISO 2531 K9 level pressure test. In the entire process of water intake from the water source, purification treatment, and water distribution in urban waterworks, EPDM sealing parts are applied to various equipment and pipelines. For example, in the sealing parts of equipment such as water pumps, valves, and water storage tanks, it can prevent water leakage and the entry of external impurities, ensuring the safety and stability of urban water supply. In the urban water supply network, EPDM sealing parts are used to connect pipelines of different diameters to ensure the tightness of the network and reduce the waste of water resources. -

06

063. Special Scenarios

Nuclear Power Auxiliary SystemVMQ sealing parts have passed the GB/T 13465.2 nuclear grade standard, with a gamma-ray resistance dose > 10⁶Gy.Aerospace Drinking Water CirculationEPDM materials have passed the NASA low outgassing test (total mass loss < 1%), and are suitable for the closed water system of the space station.

-

1. Material Testing

01- Chemical Stability: ASTM D573 hot air aging test (150°C × 168h, hardness change < ±5A)- Hygiene and Safety: GB/T 17219 immersion test (lead leaching amount < 0.001mg/L) -

2. Process Control

02- Compression Molding: Use a 200-500-ton flat vulcanizing machine, and strictly control the vulcanization temperature.- Dimensional Accuracy: Use a visual inspection machine with 15 cameras for multi-directional inspection, and strictly control the tolerances of key dimensions according to customer requirements.

-

011. Nano Modification: The graphene/EPDM composite material increases the fatigue resistance life by 200%.2. Intelligent Sealing: The EPDM sealing ring integrated with an optical fiber sensor realizes real-time leakage monitoring.3. Environmentally Friendly Process: The technology without in-mold spraying reduces the VOC emissions by 90%.

011. Nano Modification: The graphene/EPDM composite material increases the fatigue resistance life by 200%.2. Intelligent Sealing: The EPDM sealing ring integrated with an optical fiber sensor realizes real-time leakage monitoring.3. Environmentally Friendly Process: The technology without in-mold spraying reduces the VOC emissions by 90%. -

Conclusion

02The peroxide EPDM sealing parts of our company have passed the authoritative certifications of 12 countries/regions, maintain stable performance within the temperature range of -55°C to 150°C and the pressure range of 0-20MPa, and the leakage rate is controlled within the ISO 5208 Class A standard. The products have been successfully applied to more than 500 municipal water supply projects worldwide and over 100,000 high-end residential water purification systems, providing full-life-cycle protection for drinking water safety.