Customized Silicone Rubber Sealing Parts

Innovative Applications of Customized Silicone Rubber Sealing Parts in the Electronic and Electrical Industry

1. Personal Care Field

-

Sealing Solution for High-end Shavers

01

Specially designed irregular sealing parts for a well-known electric shaver brand, precisely fitting the complex structure inside the shaver head. The surface is sprayed with an O-ring to improve the assembly efficiency. These sealing parts can effectively block moisture and dust, protect the internal precision components, and enhance the durability and performance of the shaver. The raw materials have passed the JIS S3200-7 food contact grade certification, taking into account both water resistance and anti-aging performance.

-

Core Sealing Components of Teeth Washers

02

Customized miniature silicone rubber sealing rings can withstand the impact of high-frequency water flow and the corrosion of oral cleansers. They comply with the EN681-1 dynamic sealing standard, ensuring the long-term stable operation of the equipment.

2. Innovative Applications in Kitchen Appliances

-

Sealing System of Smart Coffee Machines

01

Customized sealing parts dedicated to multi-brand fully automatic coffee machines. The high-temperature resistance (-60℃~250℃) characteristic ensures zero leakage of the extraction system. They can play a sealing role for different components of the coffee machine, prevent the leakage of coffee liquid and steam, ensure the stability of the brewing process, and guarantee the quality of the coffee. These sealing parts have passed the triple beverage contact safety certifications of NSF61/ACS/KTWW270.

-

Precise Sealing Solution for Dishwashers

02

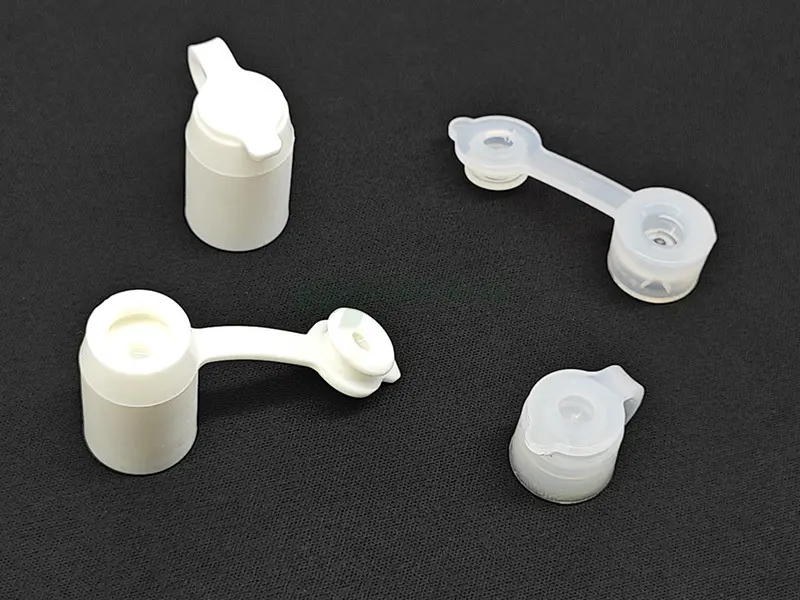

Irregular sealing parts for the dishwasher powder lids of leading brands comply with the PAK/PAH environmental protection limit values. They optimize the damping feeling during opening and closing, seal the lids, prevent the leakage of dishwasher powder, and effectively isolate the erosion of water vapor and the penetration of detergents. This ensures the normal and efficient operation of the dishwasher.

-

Safety Sealing Rings for Pressure Cookers

03

With a multi-layer composite structure design, it can withstand a working pressure of more than 20kPa. It has passed the dual certifications of AS NZS4020+FDA, ensuring zero safety hazards during the cooking process and efficient operation.

3. Smart Home Solutions

-

Protection Sealing of Washing Machine Motors

01

Customized silicone rubber sealing sleeves dedicated to miniature motors, with IP68-level waterproof and dustproof performance, comply with the DVGW/UBA-LL standards for water-related components. They can protect the motor from moisture and debris, reduce the risk of motor failure, extend the service life of the washing machine, and effectively isolate the intrusion of detergents and clothing fibers.

-

Pump Sealing of Well-known Brands' Products such as Robotic Vacuum Cleaners, Blood Pressure Monitors, Coffee Machines, Hair Dryers, Beauty Devices, and Smart Toilets

02

Precise sealing components for miniature pumps have passed the 100,000-time dynamic wear test. The materials have passed the Ö-NORM/LMG wear resistance certification, which can ensure the normal operation of the pumping system, help the robotic vacuum cleaner to efficiently vacuum and collect dust, and the silent design improves the user experience.

4. Food Brewing and Water Purification Equipment

-

Sealing Module of Smart Brewing Machines

01

Irregular sealing parts resistant to alcohol corrosion meet the special requirements of the fermentation environment. They have passed the dual system certifications of KIWA/WRAS and are suitable for the standards of global brewing equipment. They can prevent the leakage of wine liquid, maintain the environment required for fermentation, and contribute to brewing high-quality wine.

-

Sealing Network of the Whole-house Water Purification System

02

Covering more than 30 key connection points of pipeline machines and water purifiers, customized silicone rubber sealing components comply with the WQA+WRc international water quality certifications and effectively prevent the precipitation of heavy metals. They effectively prevent water leakage and ensure the stable operation of the equipment, providing users with clean drinking water.

Technical Advantages

-

01

- Global Compliance Assurance: The raw materials have passed more than 20 national access standards such as AS NZS4020 (Australia and New Zealand), JFSL 370 (Japan), KTW/W270 (Germany), NSF61 (the United States), ACS (France), WRAS (the United Kingdom), and EN681-1 (the European Union).

- A database of over 6,000 mature products can quickly respond to customization needs. With more than 20 years of mold design and development capabilities, it can develop rubber products of various structures.

- The accuracy of the automatic 3D scanning modeling can reach ±0.05mm.

-

02

- Passed the UL94 V-0 flame retardant certification and RoHS environmental protection testing.

- Supports special coating treatments such as UV resistance and antistatic.

- Mold designers, material engineers, product engineers work together with the customer's end-users to develop and design rubber sealing products.

- OEM manufacturing and processing: Design rubber formulas according to the customer's drawings, material requirements, and physical property specifications, design molds for product dimensional tolerances and structures, complete PPAP, and carry out manufacturing and production.

-

03

- Formula Design and Development Capability: With more than 20 years of formula design and development capabilities, it can develop formulas suitable for various environments, such as ASTM, JIS, MIL, drinking water certification, food-grade FDA, LFGB, high and low temperature, flame retardant, insulation, conductivity, and other requirements.

- Quality Assurance Capability: From "incoming inspection", "process sampling inspection" to "100% appearance full inspection", "dimensional sampling inspection", and "shipping sampling inspection", there is a complete and reliable quality assurance process. Use the most advanced automatic inspection machines to conduct a 100% full inspection of products.

01- Global Compliance Assurance: The raw materials have passed more than 20 national access standards such as AS NZS4020 (Australia and New Zealand), JFSL 370 (Japan), KTW/W270 (Germany), NSF61 (the United States), ACS (France), WRAS (the United Kingdom), and EN681-1 (the European Union).- A database of over 6,000 mature products can quickly respond to customization needs. With more than 20 years of mold design and development capabilities, it can develop rubber products of various structures.- The accuracy of the automatic 3D scanning modeling can reach ±0.05mm.

01- Global Compliance Assurance: The raw materials have passed more than 20 national access standards such as AS NZS4020 (Australia and New Zealand), JFSL 370 (Japan), KTW/W270 (Germany), NSF61 (the United States), ACS (France), WRAS (the United Kingdom), and EN681-1 (the European Union).- A database of over 6,000 mature products can quickly respond to customization needs. With more than 20 years of mold design and development capabilities, it can develop rubber products of various structures.- The accuracy of the automatic 3D scanning modeling can reach ±0.05mm. 02- Passed the UL94 V-0 flame retardant certification and RoHS environmental protection testing.- Supports special coating treatments such as UV resistance and antistatic.- Mold designers, material engineers, product engineers work together with the customer's end-users to develop and design rubber sealing products.- OEM manufacturing and processing: Design rubber formulas according to the customer's drawings, material requirements, and physical property specifications, design molds for product dimensional tolerances and structures, complete PPAP, and carry out manufacturing and production.

02- Passed the UL94 V-0 flame retardant certification and RoHS environmental protection testing.- Supports special coating treatments such as UV resistance and antistatic.- Mold designers, material engineers, product engineers work together with the customer's end-users to develop and design rubber sealing products.- OEM manufacturing and processing: Design rubber formulas according to the customer's drawings, material requirements, and physical property specifications, design molds for product dimensional tolerances and structures, complete PPAP, and carry out manufacturing and production. 03- Formula Design and Development Capability: With more than 20 years of formula design and development capabilities, it can develop formulas suitable for various environments, such as ASTM, JIS, MIL, drinking water certification, food-grade FDA, LFGB, high and low temperature, flame retardant, insulation, conductivity, and other requirements.- Quality Assurance Capability: From "incoming inspection", "process sampling inspection" to "100% appearance full inspection", "dimensional sampling inspection", and "shipping sampling inspection", there is a complete and reliable quality assurance process. Use the most advanced automatic inspection machines to conduct a 100% full inspection of products.

03- Formula Design and Development Capability: With more than 20 years of formula design and development capabilities, it can develop formulas suitable for various environments, such as ASTM, JIS, MIL, drinking water certification, food-grade FDA, LFGB, high and low temperature, flame retardant, insulation, conductivity, and other requirements.- Quality Assurance Capability: From "incoming inspection", "process sampling inspection" to "100% appearance full inspection", "dimensional sampling inspection", and "shipping sampling inspection", there is a complete and reliable quality assurance process. Use the most advanced automatic inspection machines to conduct a 100% full inspection of products.