As we look ahead to 2025, the landscape of home appliances continues to evolve, with innovative technologies and design trends shaping the way we interact with everyday items. Among these advancements, the Rubber Gasket Washing Machine stands out as a pivotal component in both functionality and efficiency. The rubber gasket, often an overlooked element, plays a crucial role in ensuring that washing machines operate smoothly and effectively, preventing leaks and maintaining optimum performance.

In this ultimate guide, we will explore the top trends influencing the development and enhancement of the Rubber Gasket Washing Machine. From advancements in materials that offer greater durability and resistance to wear, to design changes that improve usability and energy efficiency, it is essential to understand how these trends will impact consumers and manufacturers alike. By delving into the innovations surrounding this vital appliance, we aim to provide insight into what the future holds for the industry and how households can benefit from these improvements in their laundry experience.

In 2025, the rubber gasket production industry is poised for remarkable innovations that will enhance efficiency and sustainability. One significant trend is the integration of smart manufacturing technologies. By utilizing IoT and AI, manufacturers can streamline their production processes, enhance quality control, and reduce waste. This not only improves the overall efficiency of gasket production but also enhances product performance, meeting the rising demands of modern washing machines.

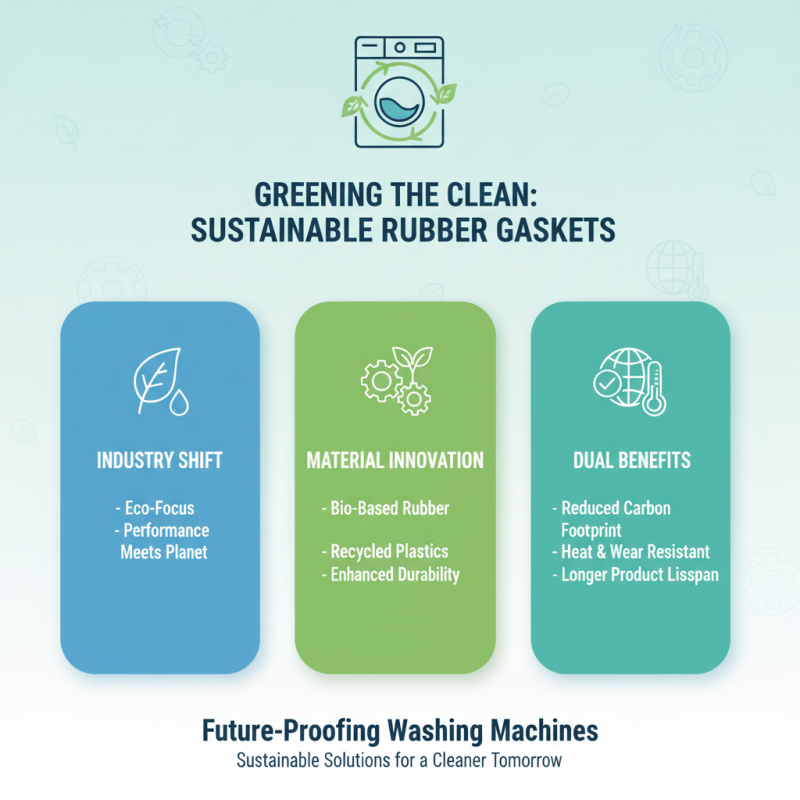

Another key development is the shift towards eco-friendly materials. As environmental concerns grow, the focus on sustainable alternatives in rubber gasket production is becoming increasingly evident. Manufacturers are experimenting with bio-based rubber compounds and recycled materials, reducing the ecological footprint of their products while maintaining durability and effectiveness. This approach not only appeals to environmentally conscious consumers but can also reduce manufacturing costs in the long run.

Tips: When considering rubber gaskets for washing machines, look for products made from sustainable materials and those featuring advanced manufacturing techniques. These options not only contribute to a greener planet but may also offer enhanced longevity and performance. Additionally, keep an eye on manufacturers that leverage technology for precision and customization, ensuring that your gasket needs are met with the highest standards.

The growing emphasis on sustainability is reshaping the rubber gasket industry, particularly for applications like washing machines. As manufacturers seek to improve both performance and environmental impact, the use of sustainable materials is becoming a key trend. Innovations in bio-based rubbers and recycled plastics are now being explored, not only to reduce carbon footprints but also to enhance gasket longevity and resilience against wear and heat. These materials can provide the necessary flexibility and durability while aligning with eco-friendly practices.

When considering sustainable materials for rubber gaskets, it’s essential to evaluate their compatibility with detergent and heat exposure. Choosing materials specifically designed to withstand harsh environments can extend the life of gaskets and improve overall efficiency. Tips for this include consulting with materials scientists about the latest advancements and conducting thorough testing in real-world conditions to ensure performance standards are met.

In addition, the circular economy concept is gaining traction within the industry. By designing rubber gaskets that can be easily disassembled and recycled, manufacturers can significantly reduce waste. Emphasizing modular designs allows for easier replacements, minimizing the need to discard entire components. Keep an eye on industry standards and certifications that promote sustainability, as these can guide informed decisions on material selection and manufacturing processes.

The advancements in cleaning technologies for washing machines are poised to revolutionize the way we maintain rubber gaskets in 2025. As users become more aware of the importance of keeping these components clean, innovative cleaning solutions are being developed to ensure efficiency and longevity. These technologies focus on enhancing the performance of washing machines by minimizing residue buildup and preventing mold and mildew, which can compromise the integrity of the rubber gasket over time.

One significant trend is the integration of ultrasonic cleaning systems, which utilize high-frequency sound waves to dislodge dirt and grime from rubber surfaces without causing damage. This method not only provides a thorough cleaning but also minimizes the use of harsh chemicals, making it an environmentally friendly option. Additionally, smart washing machines are increasingly being equipped with built-in cleaning cycles specifically designed for gaskets, allowing users to automate the maintenance process with ease.

Tips for maintaining your rubber gasket include regularly inspecting it for signs of wear and tear, cleaning it with a mixture of vinegar and water to remove any stubborn buildup, and ensuring that the washing machine door is left ajar after use to allow for air circulation. By staying proactive in your maintenance routine and leveraging new cleaning technologies, you can extend the lifespan of your washing machine and enjoy optimal cleaning results for years to come.

The market for rubber gaskets in household appliances, particularly washing machines, is expected to see significant growth by 2025. As consumers increasingly prioritize energy efficiency and durability, manufacturers are responding by integrating advanced materials and innovative designs in rubber gaskets. This change is driven not only by the need for improved appliance performance but also by heightened consumer awareness regarding sustainability and environmental impact. The demand for high-quality rubber gaskets is anticipated to rise as households seek products that offer longevity and reduced maintenance costs.

Furthermore, as smart technologies make their way into home appliances, the need for reliable sealing solutions becomes crucial. Rubber gaskets play a pivotal role in ensuring that washing machines operate effectively, preventing leaks and enhancing overall efficiency. The ongoing trends towards automation and connectivity in household appliances will likely amplify the need for precision-engineered gaskets. Anticipated advancements in gasket materials, including the adoption of recycled and eco-friendly options, are expected to align with consumer expectations and regulatory guidelines, fueling market demand in the coming years.

| Trend | Market Demand (Million Units) | Growth Rate (%) | Key Drivers |

|---|---|---|---|

| Increased Durability and Flexibility | 150 | 5.5 | Consumer Preference for Long-lasting Products |

| Eco-friendly Materials | 120 | 8.0 | Regulatory Pressure and Consumer Awareness |

| Customizable Designs | 90 | 6.0 | Demand for Personalization |

| Integration with Smart Technology | 110 | 7.5 | Rise of Smart Home Appliances |

| Enhanced Sealing Performance | 130 | 4.5 | Consumer Demand for Energy Efficiency |

The rubber gasket manufacturing industry is experiencing a significant transformation, largely driven by evolving regulatory standards. In 2025, manufacturers will face increased scrutiny regarding materials and processes used in gasket production. Compliance with stringent environmental regulations aimed at reducing waste and emissions will be a priority, compelling companies to adopt more sustainable practices. Innovations in material science, including the development of eco-friendly rubber compounds, are expected as manufacturers strive to meet these new standards while maintaining performance and durability.

Additionally, safety regulations will play a crucial role in shaping the future of rubber gasket manufacturing. Enhanced testing protocols will require manufacturers to ensure that their products are free from harmful substances and can withstand diverse operational conditions. As customers become more environmentally conscious, the demand for certified eco-friendly products is expected to rise. Consequently, companies that proactively align their processes with regulatory requirements will likely gain a competitive advantage, positioning themselves as leaders in both innovation and sustainability within the rubber gasket market.