In the ever-evolving landscape of manufacturing, molded rubber parts represent a cornerstone of innovation and efficiency across various industries. From automotive components to medical devices, the demand for high-quality molded rubber parts is on the rise. According to the latest market analysis report by Grand View Research, the global molded rubber market is projected to reach USD 31.75 billion by 2025, growing at a CAGR of 4.2%. This significant growth underscores the critical role that molded rubber parts play in enhancing product durability and performance.

Experts like Dr. John Carter, a distinguished figure in the molded rubber industry, emphasize the importance of these components in modern engineering projects. He states, "The versatility of molded rubber parts not only meets the rigorous demands of high-stress applications but also contributes to overall design efficiency." As projects increasingly prioritize sustainability and resilience, understanding the types and applications of molded rubber parts becomes essential for engineers and project managers alike.

As we delve into the top 10 molded rubber parts you need to know, we will explore their functionalities, advantages, and the innovative technologies that are shaping their future. Recognizing these vital components will empower professionals to make informed decisions that enhance project outcomes and align with industry standards.

Molded rubber parts play a crucial role in various industries due to their versatile applications and unique properties. These parts are created by molding rubber into specific shapes and sizes, allowing for a tailored approach to meet specific project requirements. Common applications include seals, gaskets, and vibration dampeners, which rely on rubber's inherent flexibility, durability, and resistance to weathering. The ability to manufacture parts that can withstand extreme temperatures and provide excellent shock absorption makes molded rubber essential in automotive, aerospace, and industrial sectors.

Understanding the manufacturing techniques of molded rubber parts is vital for optimizing their use in projects. Techniques such as compression molding, transfer molding, and injection molding each offer distinct advantages depending on the design complexity and production volume. The selection of rubber compounds is equally important, as different formulations can enhance properties such as elasticity, tear resistance, and chemical compatibility. By recognizing these aspects, engineers and designers can effectively leverage molded rubber parts to enhance performance and reliability in their applications, ultimately driving project success.

Molded rubber parts have become an essential component in various projects due to their numerous advantages. One of the key benefits of using molded rubber is their excellent durability. These parts are designed to withstand harsh environmental conditions, making them ideal for applications in automotive, industrial, and consumer products. The resilience of molded rubber helps in reducing wear and tear, ultimately extending the lifespan of the components and minimizing replacement costs.

Another significant advantage is the versatility of molded rubber materials. They can be formulated to meet specific requirements, including varying levels of hardness, thermal resistance, and chemical exposure. This adaptability allows engineers and designers to customize parts to suit their unique project needs. Additionally, molded rubber offers superior flexibility and shock absorption, which is crucial in applications where impact resistance is necessary. This combination of durability and adaptability makes molded rubber parts a preferred choice across diverse industries and contributes to their increasing popularity in modern engineering solutions.

This chart displays the market demand for the ten most commonly used molded rubber parts in various projects. The data reflects the estimated units required for each type, illustrating the importance of these components in manufacturing and engineering applications.

Molded rubber parts are essential components utilized across various industries due to their flexibility, durability, and resistance to various environmental factors. One common type of molded rubber part is the O-ring, which is primarily used for sealing applications. These circular rings provide an effective barrier against liquids and gases while accommodating movement and pressure changes. Their versatility makes them ideal for hydraulic systems, automotive applications, and household items.

Another prevalent type is rubber gaskets, which serve as seals between different surfaces to prevent leakage. Available in various shapes and sizes, they are widely used in machinery, plumbing, and automotive industries. Their design can be tailored to withstand extreme temperatures and corrosive environments, enhancing their reliability. Additionally, molded rubber bumpers provide cushioning and shock absorption, helping to protect machinery and equipment from impact damage. These features make molded rubber parts not only functional but also crucial in optimizing the performance and longevity of various products.

When choosing molded rubber parts for your projects, there are several crucial factors to consider to ensure you select the right materials for your application. Firstly, it's important to assess the specific mechanical properties required for your project, such as tensile strength, elasticity, and wear resistance. Understanding the operational conditions, like temperature variations and exposure to chemicals, will help you determine the best rubber type that can withstand these environments.

Another important aspect to keep in mind is the manufacturing process of the molded parts. Different techniques can influence the quality and cost of the final product. It’s advisable to consider whether the parts need to be custom-made or if standard sizes will suffice. Properly evaluating your production volume requirements is also essential, as it can greatly affect the cost-effectiveness of your choice.

Tips: Always request sample parts when possible, as they can provide valuable insights into color, texture, and fit. Additionally, collaborating with a supplier who has experience in your industry can help guide you in selecting the most suitable rubber types for your specific applications, ensuring longevity and reliability in your final products.

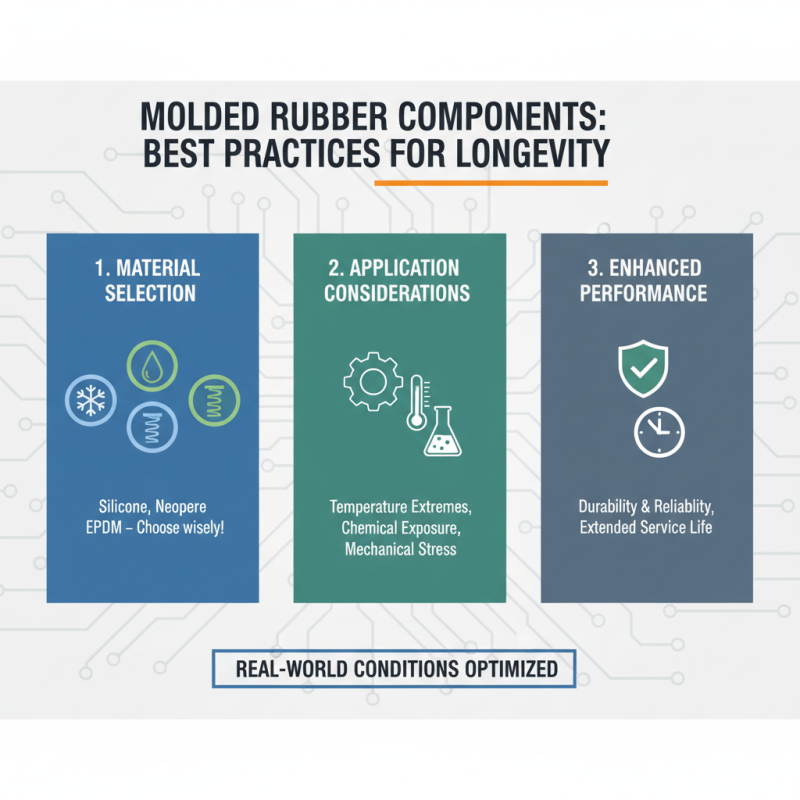

When working with molded rubber components, understanding the best practices can significantly enhance the effectiveness and longevity of your projects. One crucial aspect is ensuring that you select the right type of rubber material for your specific application. Different formulations, such as silicone, neoprene, or EPDM, offer varying levels of flexibility, resistance to temperature extremes, and chemical adaptability. This choice directly influences the performance of the molded parts in real-world conditions.

**Tips:** Before finalizing your choice, conduct thorough research on the characteristics of each rubber type related to your project needs. Additionally, consider the environmental factors the parts will be exposed to, such as UV light, moisture, and chemicals, which can affect their durability over time.

Another essential practice is proper mold maintenance. Regular inspections and cleaning of the molds can prevent defects and inconsistencies in production. Contaminants can lead to surface imperfections that not only compromise aesthetics but also functionality. Moreover, ensuring optimal curing conditions by monitoring temperature and humidity can result in stronger and more reliable components.

**Tips:** Utilize a checklist for mold inspection and cleansing routines to guarantee a systematic approach. Additionally, invest in training for your team on the importance of these protocols to foster a culture of quality and attention to detail in the manufacturing process.