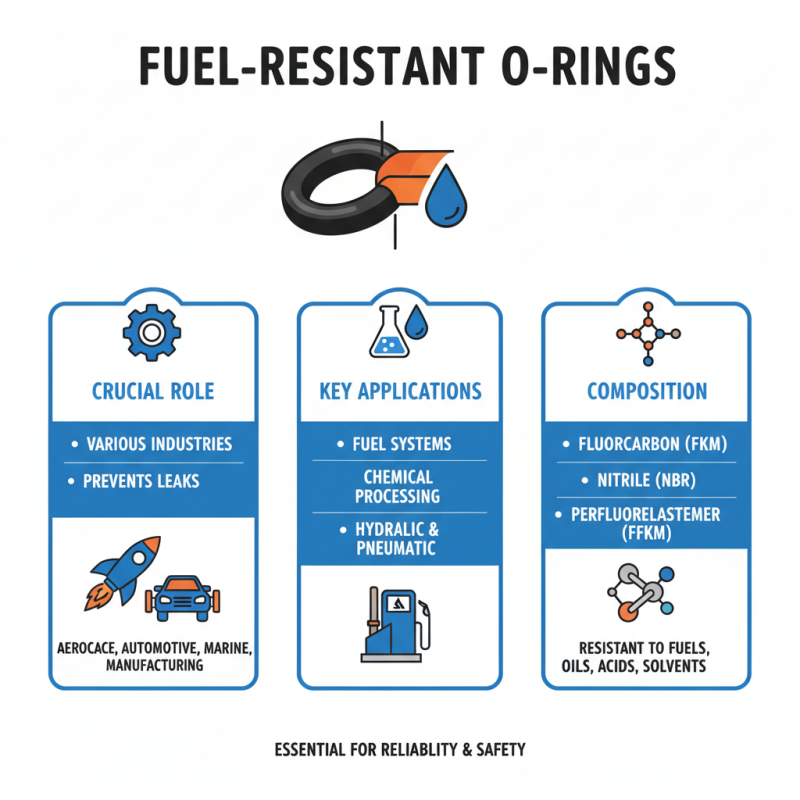

Fuel Resistant O Rings are crucial components in various machinery and automotive applications. These specialized O-rings are designed to withstand exposure to fuels and other harsh chemicals. They play a vital role in preventing leaks, ensuring system integrity, and protecting sensitive components.

Understanding how Fuel Resistant O Rings work is essential for anyone involved in maintenance or design. These O-rings are made from materials like fluorocarbon, which offer excellent resistance to fuel degradation. They create a tight seal, minimizing the risk of leaks. However, not all O-rings are created equal. Users should consider factors like temperature and pressure when selecting the right type.

Many people overlook the importance of regular checks on these components. Fuel Resistant O Rings can deteriorate over time, leading to failures. Neglecting maintenance can result in costly repairs and unsafe conditions. Awareness and proper care can extend the lifespan of these important seals. A proactive approach is key to ensuring your systems run smoothly.

Fuel resistant O-rings are vital components in many mechanical systems. They are designed to withstand exposure to various fuels, oils, and other harsh chemicals. These O-rings are typically made from special rubber compounds that resist degradation. Common materials for fuel resistant O-rings include fluorocarbon and nitrile rubber. These materials help prevent leaks by providing a tight seal.

Understanding how fuel resistant O-rings work is important. When installed, these O-rings fit snugly into designated grooves. This design allows them to create pressure seals that keep fluids contained. As fluids move, the pressure from the fluid pushes the O-ring against the housing, enhancing the seal. However, factors like temperature fluctuations and chemical composition can affect their longevity.

Sometimes, fuel resistant O-rings fail when exposed to extreme conditions. Users might notice cracks or swelling, which could lead to leaks. Regular inspections are crucial to ensure they still perform effectively. It’s essential to choose the right O-ring for specific applications to avoid premature failure. Understanding the environment where the O-ring will be used can make a significant difference.

Fuel resistant O-rings play a crucial role in various industries. They are essential for applications involving fuels and other aggressive chemicals. Understanding their composition can shed light on their effectiveness.

These O-rings are typically made from specific materials designed to withstand fuel exposure. Common choices include fluorocarbon elastomers and nitrile rubber. Fluorocarbon offers excellent chemical resistance. Nitrile, while effective, can degrade faster under high heat. The right choice often depends on the specific application and the environment.

Choosing the wrong material can lead to failures. For example, using standard rubber in fuel systems may result in leaks. Such failures can be costly and dangerous. It's vital to consider factors like temperature and chemical exposure. This ensures a proper seal and longevity of the O-ring.

Fuel resistant O-rings are essential in the automotive industry. They help create tight seals in fuel systems. These O-rings resist degradation caused by fuel exposure. They enhance the reliability of fuel pumps and injectors. Without them, leaks can occur, leading to potential hazards.

In fuel tanks, these O-rings ensure no fuel escapes. Even small leaks can lead to serious engine issues. In addition, they protect against fuel vapor emissions. This keeps the environment cleaner and safer for everyone. Engineers select materials that withstand diverse fuel types and extreme temperatures.

Tips: Always ensure proper installation of O-rings for maximum effectiveness. Regularly inspect O-rings for signs of wear or damage. Sometimes you might miss a subtle crack. Ignoring small issues can lead to larger problems down the line. Pay attention to these details for optimal vehicle performance.

Fuel resistant O-rings are essential components in many fuel systems. They function by creating a tight seal, preventing fuel leaks. Made from special materials, these O-rings withstand harsh chemicals and high temperatures. This ensures durability and safety in various applications, from automotive to aerospace.

When installed correctly, these O-rings can effectively seal connections and joints. They block fuel from escaping, which helps to maintain system integrity. Properly chosen and installed O-rings can greatly reduce the risk of leaks. It's vital to consider the specific environment where these O-rings will be used.

Tips: Regular maintenance is key to fuel system safety. Inspect O-rings periodically for signs of wear. If you notice cracks or deformation, replace them promptly. Choose the right material for your application. Sometimes, the wrong choice can lead to unexpected failures. Keep in mind, not all materials perform equally under different fuel types.

| Property | Description |

|---|---|

| Material | Nitrile Rubber (NBR), Fluoroelastomer (FKM) |

| Temperature Resistance | -40°F to 400°F (-40°C to 204°C) |

| Chemical Compatibility | Resistant to gasoline, diesel, and other petroleum products |

| Usage | Commonly used in fuel systems, engines, and hydraulic applications |

| Functionality | Seals under pressure to prevent leaks of fluids and gases |

| Maintenance | Regular inspections for wear and tear recommended |

| Lifespan | Typically lasts 5-10 years depending on usage and conditions |

Fuel resistant O-rings play a critical role in maintaining the integrity of fuel systems. These O-rings are made from specialized materials that withstand harsh environments. They help prevent leaks and ensure optimal performance. However, like all components, their lifespan is limited.

Regular maintenance is vital for these seals. A report from the Society of Automotive Engineers (SAE) states that improper installation can reduce their lifespan by 30%. The environmental factors, such as temperature and chemical exposure, significantly affect their durability. For instance, constant exposure to fuel can degrade the material over time. It is recommended to inspect O-rings every 6 months for signs of wear.

Lifespan varies based on usage. Some O-rings can last up to 10 years, while others may fail within a year. Understanding the conditions in which they operate is key. Poor maintenance practices often lead to premature failure. Data suggests that improper handling can contribute to 20% of O-ring failures. Regular checks and timely replacements can enhance overall system reliability.