When embarking on a project that requires sealing solutions, one of the most crucial components to consider is the Rubber Gasket Ring. These rings serve as essential components in various applications, providing effective sealing to prevent leaks and ensure proper functioning of equipment. Choosing the right rubber gasket ring involves understanding the specific requirements of your project, including factors such as material compatibility, temperature ranges, and pressure conditions.

In this guide, we will explore the key considerations to help you make informed decisions regarding rubber gasket rings. By examining the different materials available, their unique properties, and the scenarios in which they excel, you will gain the knowledge necessary to select the most suitable gasket for your needs. Additionally, we will address common challenges faced during the selection process and offer practical tips to ensure a successful outcome in your sealing applications. Whether you're working on industrial projects, automotive applications, or home repairs, understanding the nuances of rubber gasket rings is essential for achieving optimal performance and reliability.

When selecting rubber gasket rings for various projects, understanding the different types available and their specific applications is essential. Common types include O-rings, flat gaskets, and spiral wound gaskets. O-rings, typically in circular shapes, are widely used for sealing applications where two components meet, ensuring a tight seal to prevent leaks in hydraulic systems and machinery. Their versatility and ease of installation make them a popular choice across various industries.

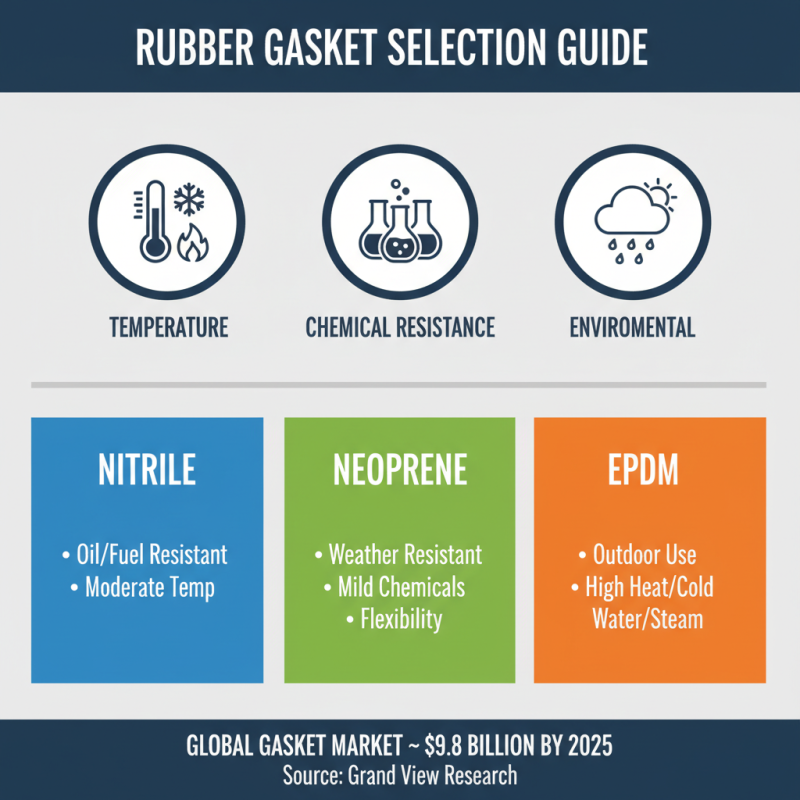

Flat gaskets, often made from rubber sheets, are ideal for applications involving flanged connections. They offer an effective sealing solution for pipes and valves, providing resistance against fluids and gases. The material choice for flat gaskets can vary based on the operating environment, with options like nitrile rubber suited for oil resistance, while EPDM is excellent for extreme temperatures and weather conditions. On the other hand, spiral wound gaskets combine layers of metal and flexible material, typically used in high-pressure environments, making them suitable for heavy-duty applications in power plants and refineries. Each type of gasket plays a critical role in ensuring the efficiency and reliability of mechanical systems, highlighting the importance of selecting the right type for specific needs.

| Type of Rubber Gasket Ring | Material | Temperature Range | Applications | Advantages |

|---|---|---|---|---|

| Nitrile Rubber Gasket | Nitrile (Buna-N) | -30°F to 250°F (-34°C to 121°C) | Automotive, Oil & Gas | Excellent oil resistance |

| EPDM Rubber Gasket | EPDM | -40°F to 300°F (-40°C to 149°C) | Roofing, Automotive | Outstanding weather resistance |

| Silicone Rubber Gasket | Silicone | -100°F to 500°F (-73°C to 260°C) | Food Service, Medical | Excellent temperature stability |

| Neoprene Rubber Gasket | Neoprene | -40°F to 200°F (-40°C to 93°C) | Electrical, Refrigeration | Great chemical stability |

When selecting the right rubber gasket ring for your projects, several key factors should be taken into consideration to ensure optimal performance and longevity. One of the most critical factors is the material composition of the gasket. Different types of rubber, such as Nitrile, Neoprene, and EPDM, offer varying levels of resistance to temperature, chemicals, and environmental conditions. According to a recent market analysis conducted by Grand View Research, the global gasket market is expected to reach $9.8 billion by 2025, highlighting the importance of selecting high-quality materials that meet industry standards.

Another vital aspect is the design and size of the gasket. Ensuring a proper fit is essential to prevent leaks and maintain pressure in applications ranging from automotive to industrial equipment. As identified by the Society of Automotive Engineers, over 30% of mechanical failures result from improper sealing solutions, which often stem from inadequate gasket selection. Thus, precise measurements and an understanding of the application requirements—such as operating temperature and pressure—are crucial to achieving a reliable seal.

Additionally, it is essential to consider the environment in which the gasket will operate. Factors such as exposure to oils, greases, and extreme weather conditions can significantly affect performance. The International Organization for Standardization (ISO) recommends performing a thorough analysis of the application conditions to determine the most suitable rubber compound and to ensure compliance with relevant industry specifications. By carefully evaluating these elements, you can make informed decisions that enhance the efficiency and durability of your projects.

When selecting a rubber gasket ring for your projects, understanding the material properties is crucial to ensure optimal performance and longevity. Rubber gaskets can be made from various compounds, each possessing unique characteristics that influence their resistance to temperature, pressure, and chemical exposure. For instance, certain rubbers offer superior flexibility and compression set resistance, making them suitable for applications that require a tight seal under fluctuating conditions. In contrast, others may exhibit exceptional resilience to harsh chemicals, which is vital in environments where exposure to corrosive substances is a concern.

The Shore hardness of the rubber is another significant factor affecting gasket performance. Softer gaskets may provide better sealing capabilities due to their ability to deform and conform to the surface irregularities of the mating parts, while harder materials may be more resistant to wear and tear. Additionally, the elastomer’s temperature tolerance helps determine its applicability in high-heat environments, where certain materials may degrade more rapidly than others. Ultimately, selecting the right rubber gasket involves a thoughtful consideration of these material properties, ensuring that your choice aligns with the specific demands of your project and contributes to the overall efficiency and safety of the system.

This chart illustrates the elongation at break percentage of different rubber gasket materials, which is a crucial factor affecting gasket performance in various applications. Understanding these properties helps in selecting the right material for specific project requirements.

When it comes to installing rubber gasket rings, following best practices can significantly enhance the performance and longevity of your project. One key guideline is to ensure that the surface where the gasket will sit is clean and free from any debris, oil, or contaminants. Research indicates that approximately 15% of gasket failures are attributed to poor surface preparation, highlighting the importance of this initial step. It's advisable to use a suitable cleaning solution that won't damage the material of the gasket or the surfaces involved.

Another vital aspect is proper torque application during installation. Over-tightening can lead to compression set or deformation of the gasket material, ultimately leading to leaks. According to a study by the Fluid Sealing Association, nearly 30% of gasket failures arise from incorrect installation practices, including improper torque. Using a calibrated torque wrench and following manufacturer recommendations for specific torque values can ensure an even and secure fit.

Tips for Successful Installation:

Proper maintenance of rubber gasket rings is crucial for ensuring their longevity and effectiveness in various applications. According to a report by the Industrial Rubber Products Association, improper handling and maintenance can lead to a significant reduction in the lifespan of gasket rings, with some materials showing a failure rate as high as 30% within the first year of installation if not cared for properly. To mitigate these risks, it is essential to adhere to a routine maintenance schedule that includes regular inspections and cleaning.

One effective maintenance practice is to regularly check the compression and material integrity of the gasket rings. Visual inspections should focus on signs of wear, such as cracks, deformation, or chemical degradation. A study from the American Society for Testing and Materials reveals that environmental factors such as exposure to oils, solvents, or extreme temperatures can accelerate wear. Additionally, implementing a proper installation technique and ensuring that the contact surfaces are clean and smooth can maximize seal effectiveness. Maintaining a clean environment around the gasket area can also prevent contamination, further extending the life of the gasket.

Furthermore, temperature control plays a pivotal role in gasket longevity. The same ASTM study indicates that maintaining operational temperatures within the recommended range for specific gasket materials can reduce failure rates by up to 25%. Investing in temperature monitoring devices can help ensure that conditions remain optimal, thereby enhancing the performance and durability of rubber gasket rings in various industrial applications.