Choosing the right Red Rubber O Ring for your project can be challenging. Many factors influence your selection, including size and material. Red Rubber O Rings are popular for their durability and flexibility in various applications.

When considering these O Rings, it’s essential to assess the specific needs of your project. The environment where they will be used plays a crucial role. Will they face extreme temperatures or exposure to chemicals? Identifying these factors can save you time and effort in the long run.

One may overlook small details, like compatibility with fluids or pressure ratings. This could lead to failures. It’s also worth noting that a perfect fit isn’t always guaranteed. Sometimes, you may need to experiment and adjust. This process can help you reflect on your choices.

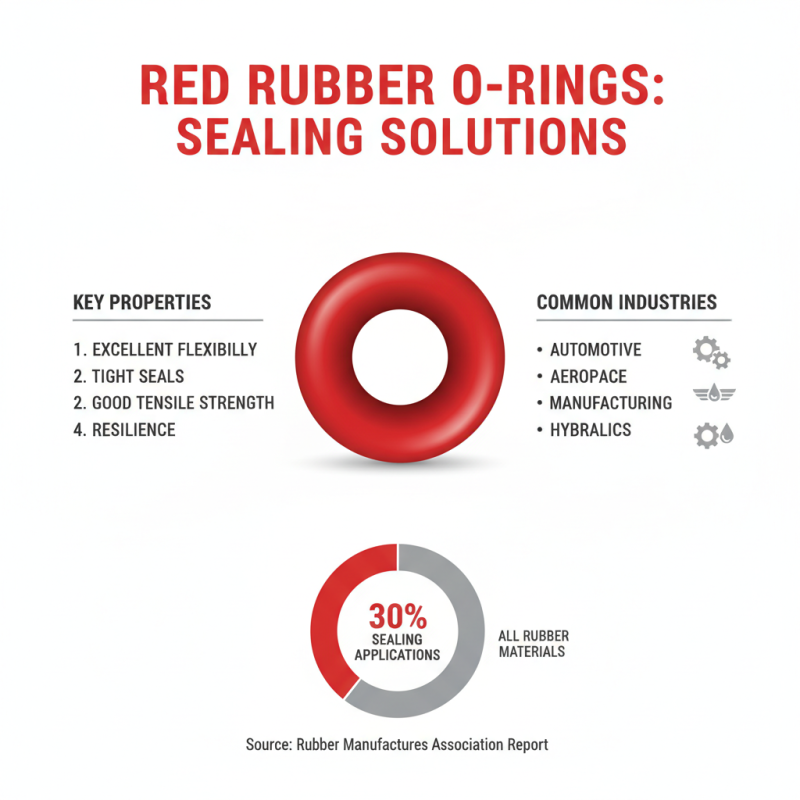

Red rubber O-rings are widely used in various sealing applications. Their unique composition offers excellent flexibility, allowing them to form tight seals. Red rubber has good tensile strength and resilience. This makes it a popular choice for many industries, including automotive and aerospace. According to a recent report by the Rubber Manufacturers Association, nearly 30% of all sealing applications use rubber materials.

Understanding the role of red rubber in sealing is essential. The material resists aging and oxidation, important for products exposed to harsh environments. Red rubber retains its sealing properties under various temperatures. However, its chemical compatibility varies. It's vital to research specific chemicals that may interact with the material. A study from the National Institute of Standards and Technology indicates that improper usage can lead to premature seal failure.

When selecting an O-ring, consider its operating conditions. The diameter and hardness are critical for performance. The durometer scale helps gauge hardness accurately, which affects flexibility. Manufacturers often neglect hardening factors, leading to ineffective seals. Performance testing shows that an ill-fitting O-ring can compromise overall system integrity. Always reflect on the long-term effects of material wear in your applications.

When selecting a red rubber O-ring, size is essential. Ensure you measure the inner diameter, outer diameter, and width accurately. Common sizes vary, with standard measurements ranging from 0.1 inches to over 10 inches in diameter. A poor fit could lead to leaks or equipment failure. This precise sizing will prevent costly mistakes.

Hardness is another critical specification. Shore A hardness is the standard measure, with values often ranging from 30 to 90. Softer O-rings are more flexible but less durable. A study from the Rubber Division of the American Chemical Society highlights that the correct hardness balances flexibility and resistance to wear.

Temperature limits also determine an O-ring's effectiveness. Typical red rubber compounds can withstand temperatures between -20°F and 180°F. Extreme temperatures can lead to failure. Proper testing is crucial. An analysis by ASTM International shows that many elastomers can degrade outside their temperature range. Consider these specifications carefully to ensure optimal performance in your project.

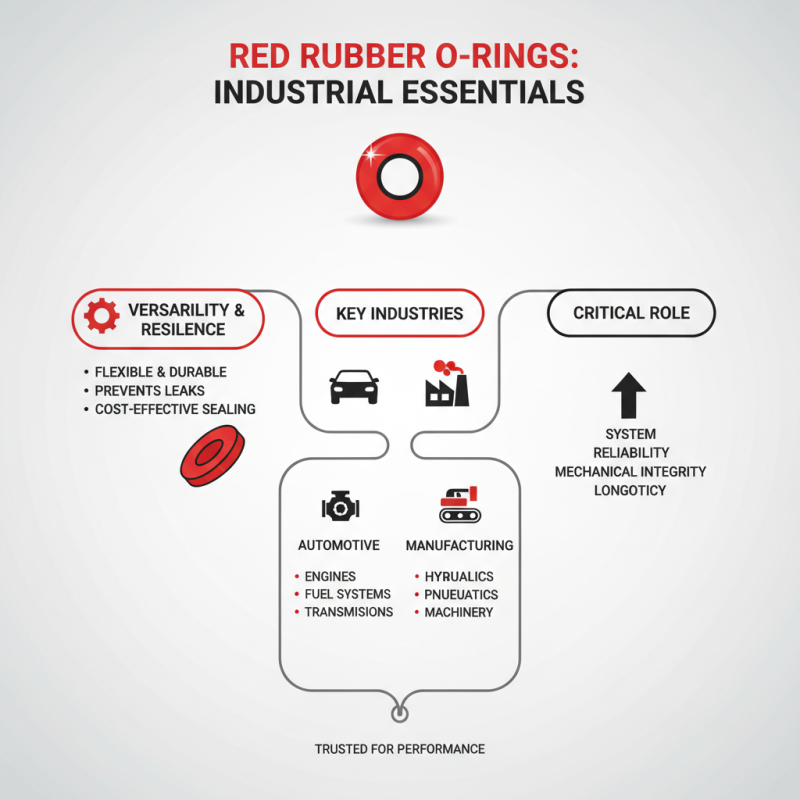

Red rubber O-rings play a vital role across various industries. Their flexibility and resilience make them a popular choice. In sectors like automotive, O-rings are essential for sealing components in engines and fuel systems. They prevent leaks that could lead to severe mechanical failures. Many manufacturers rely on them for their durable performance and cost-effectiveness.

In the food processing industry, red rubber O-rings ensure hygiene and safety. They are often found in sealing equipment, preventing contamination. These rings can withstand harsh cleaning agents, which is crucial. However, selecting an O-ring with the right hardness can be challenging. Too hard, and they may not seal properly. Too soft, and they could fail under pressure.

In pharmaceutical applications, red rubber O-rings are used for critical connections in equipment. They must meet stringent safety standards. Workers must regularly examine these seals for wear. Over time, exposure to various substances can degrade the material. Neglecting this can lead to unsafe conditions. Each application requires careful thought to avoid unintended results.

When selecting a red rubber O-ring, performance metrics are crucial. Two main metrics to consider are compression set and tensile strength. Compression set measures how well the O-ring can return to its original shape after being compressed. For instance, a lower compression set percentage typically indicates better recovery. Studies show that top-performing O-rings should have a compression set below 10% in service.

Tensile strength is another key factor. This metric determines how much force the O-ring can withstand before breaking. Research reports highlight that an O-ring with a tensile strength of at least 20 MPa is preferred for most applications. Such strength ensures durability against high pressure and temperature changes.

**Tip:** Always check the specifications of O-rings during selection to meet your project's requirements.

It's also vital to account for environmental factors. Harsh conditions can impact O-ring performance. For example, exposure to extreme temperatures can lead to premature failure.

**Tip:** Conduct real-world testing to confirm that your selected O-ring performs effectively in your specific application.

Finding the right balance between compression set and tensile strength can be challenging. Sometimes manufacturers may prioritize one metric over another, leading to trade-offs. A thorough evaluation can ensure that your project receives a reliable seal.

Choosing the right red rubber O-ring for your project involves careful consideration of multiple factors. These rings are essential in various applications, providing sealing solutions that prevent leaks. According to industry reports, nearly 30% of mechanical failures are linked to improper sealing components, emphasizing the importance of a good selection.

When selecting, consider the material properties. Red rubber O-rings typically contain EPDM, which offers excellent resistance to heat and weathering. This makes them suitable for outdoor applications. However, they may not perform well in oil or fuel environments. An estimated 15% of users face performance issues due to inappropriate material choices.

Additionally, you should evaluate size and diameter. A mismatch can lead to leaks, increasing maintenance costs. Industry data shows that up to 25% of O-ring failures result from incorrect sizing. This aspect often requires precise measurements and attention to detail. Every project has unique challenges, and overlooking any of these factors could result in failure.