The Double O Ring has gained significant popularity due to its versatility in various industries. According to a report by the Rubber Research Society, the global demand for O-rings, including Double O Rings, is projected to increase by 5% annually. This surge reflects their essential role in applications such as automotive, aerospace, and household products.

Dr. Emily Harris, an industry expert, states, "Double O Rings are game changers in sealing technology." This statement highlights their effectiveness in preventing leaks and ensuring durability. For instance, in automotive engines, these rings help maintain pressure and enhance performance.

Despite their many benefits, some users fail to recognize the importance of choosing the right material. Double O Rings made from subpar materials can lead to system failures. It's crucial to evaluate the application requirements carefully to avoid mishaps. The versatility of Double O Rings continues to reshape industries while also reminding us of the need for quality assurance.

Double O rings are essential components in plumbing applications. Their unique design allows for effective sealing, preventing leaks. These rings consist of two concentric loops, which create a reliable barrier against water. They are commonly used in faucets, pipes, and connectors.

In faucet installations, double O rings are crucial. They help maintain a tight seal between the faucet and the sink. Over time, wear and tear can cause these rings to degrade. Regular checks can improve faucet longevity significantly. Using a double O ring is a simple yet effective approach to avoiding costly leaks.

In drainage systems, double O rings also play a key role. They ensure that connections between pipes remain leak-free. This can prevent significant water damage. However, improper installation is a common issue. Always check for alignment before sealing. Overlooking this can lead to cumbersome repairs down the line. Investing in quality materials is vital for optimal performance.

Double O rings play a crucial role in automotive sealing solutions. They are designed to ensure proper sealing in various components, such as engines, transmissions, and fuel systems. According to a report by the Society of Automotive Engineers, nearly 70% of vehicle leaks are attributed to failures in seals. This statistic emphasizes the need for reliable sealing solutions.

In everyday applications, double O rings provide versatility and efficiency. Their unique design allows them to handle high pressure and temperature fluctuations. For example, they are commonly used in fuel injection systems, ensuring that fuel remains contained under extreme conditions. Minor imperfections in seal installation can lead to significant failures. This creates a need for regular inspections.

The automotive industry benefits significantly from using double O rings. They are made from materials that resist wear and tear. The right fit is essential; an incorrect size can compromise safety. A recent survey noted that 20% of vehicle malfunctions could be traced back to improper sealing. As technology evolves, improvements in materials and design may reduce these issues. However, continuous evaluation is necessary to avoid costly repairs in the long term.

Double O Rings play a crucial role in the food and beverage industry. These seals provide the necessary barrier to prevent leaks and contamination. In food processing, double O rings are commonly found in pumps and valves. Their durability ensures that beverages remain safe for consumption. According to a report from the Food Safety and Inspection Service, improper sealing can lead to significant spoilage issues.

In addition to pumps, double O rings are essential in machinery used for bottling and packaging. They maintain pressure in systems that process sparkling beverages. This helps retain carbonation and freshness. Studies indicate that effective sealing can improve product life by up to 30%. However, it is critical to regularly inspect these seals. Wear and tear can lead to failures that jeopardize food safety.

Choosing the right materials for double O rings is vital. Common materials include silicone and nitrile. Each has its specific applications and strengths. Reports show that nearly 15% of food contamination events are linked to inadequate sealing. It highlights the need for diligence in ring selection. Flawed choices can lead to costly recalls and loss of consumer trust.

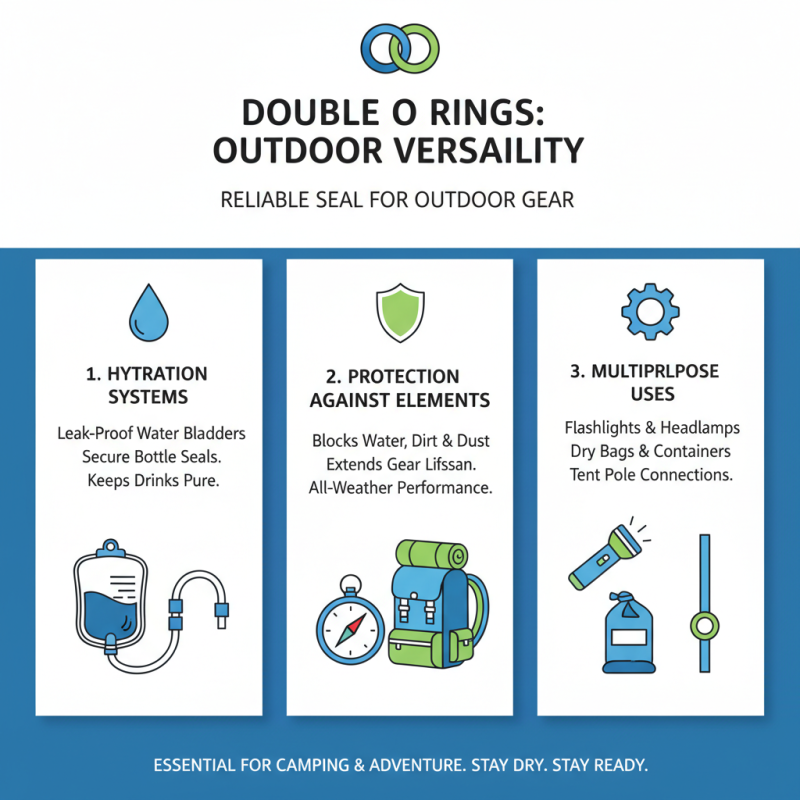

Double O rings are versatile components widely used in outdoor equipment and gear. They provide a reliable seal against water, dirt, and dust. When camping, these rings can be utilized in hydration systems, ensuring a leak-proof experience. They help in maintaining the integrity of water bladders, making them essential for outdoor adventures.

In addition to hydration systems, Double O rings have applications in tents and backpacks. They can reinforce zippers and locking mechanisms, preventing failures in the field. Sometimes, an O ring might wear out unexpectedly. This can lead to frustration, especially if you are miles away from home. A backup plan is necessary, such as carrying spare rings or a repair kit.

Using Double O rings also calls for attention to detail. Proper installation is critical. An improperly placed O ring can lead to leaks or damage. It’s vital to check for wear and tear regularly. Otherwise, your gear may not perform as expected during crucial moments. Being proactive with maintenance can save a trip from becoming a disaster.

Double O rings are increasingly popular in sealing applications for electronics and electrical devices. This unique design enhances sealing efficiency. According to industry reports, the global market for sealing solutions is expected to grow by 6% annually, driven by the demand for durable components.

In electronics, these O rings protect sensitive devices from dust and moisture. They are vital in ensuring long-term performance and reliability. A well-sealed device reduces the risk of electrical short circuits and enhances user safety. However, improper installation can lead to failures. It's crucial to follow guidelines for correct application.

Tips: Always check the compatibility of materials used with Double O rings. Ensure proper sizing to avoid leaks or excessive pressure. Regular inspections can save costs and improve device lifespan. Remember, a neglected seal can compromise an entire system.

| Application | Material | Temperature Resistance (°C) | Application Area |

|---|---|---|---|

| Electrical Enclosures | Nitrile Rubber | -40 to 100 | Electronics |

| Automotive Seals | Silicone | -50 to 180 | Vehicles |

| Hydraulic Systems | Fluoroelastomer | -20 to 200 | Industrial |

| Pneumatic Valves | EPDM | -30 to 130 | Manufacturing |

| Water Pumps | Neoprene | -20 to 90 | Electrical |

| Home Appliances | Nitrile Rubber | -40 to 100 | Household |

| Construction Machinery | Polyurethane | -30 to 100 | Heavy Machinery |

| Aerospace Seals | PTFE | -60 to 260 | Aviation |

| Marine Applications | Natural Rubber | -10 to 70 | Boats and Ships |

| Medical Devices | Silicone | -50 to 180 | Healthcare |