In the world of sealing solutions, the Parker Hannifin O Ring has established itself as a trusted name. According to industry expert Dr. Emily Carter, “Parker Hannifin O Rings provide reliability and versatility across various applications.” Understanding how to select the best O Ring for your needs can be daunting.

When considering the optimal choices, it’s essential to factor in materials, temperature ranges, and pressure conditions. Parker Hannifin offers a diverse range of O Rings designed to tackle different challenges. Each seal serves a specific purpose and environment, making careful selection crucial.

However, even with the best options, some users struggle with compatibility. Mistakes in application can lead to failures, highlighting the need for reflection on current practices. By focusing on the right Parker Hannifin O Ring, you can enhance performance and longevity. Let's delve into the top five selections that can elevate your application.

O-ring seals are crucial components found in various applications. They provide a reliable method for sealing joints and preventing fluid leaks. Made from elastomers, these seals can withstand various temperatures, pressures, and chemicals. Their simple design enables easy installation and maintenance.

However, choosing the right O-ring for a specific application can sometimes be challenging.

In industries like automotive and aerospace, O-rings play a critical role in ensuring safety and efficiency. High temperatures can affect their performance. For example, they might lose elasticity or become brittle over time. Additionally, improper sizing can lead to leaks, which can be costly and dangerous. It’s essential to pay attention to material compatibility and environmental conditions. Regular inspections and replacements are necessary to avoid potential failures.

Understanding the specific application helps in selecting the best O-ring. Different environments call for different materials. Using the wrong type can lead to significant issues. While some operations may seem straightforward, it's vital to recognize the complexities involved. Learning from past mistakes can guide better choices. The right O-ring seal makes all the difference in performance and longevity.

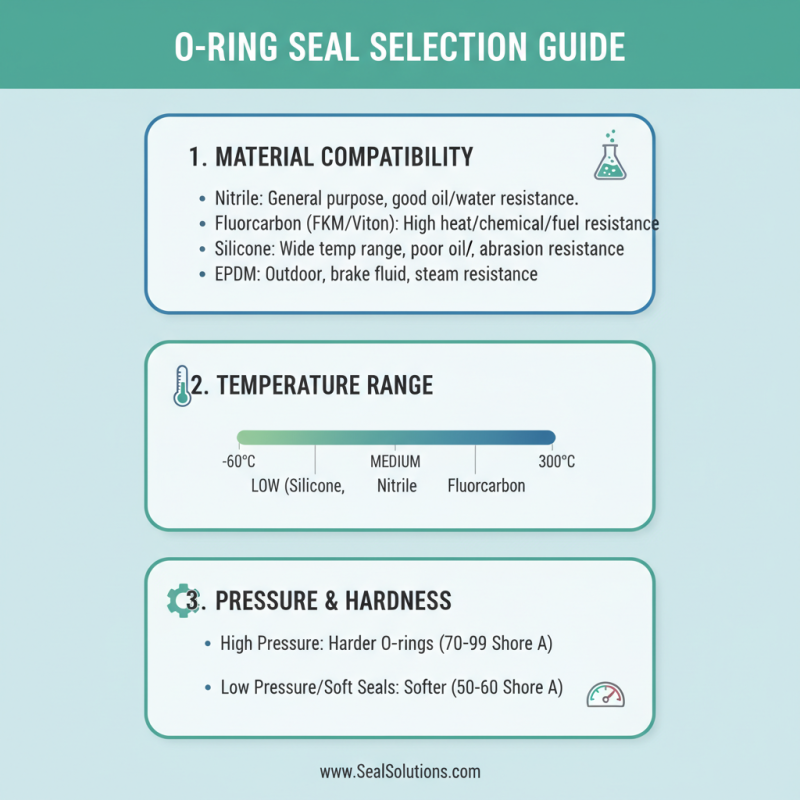

When selecting O-ring seals for various applications, it's essential to consider their key features. One primary factor is material compatibility. Different materials such as nitrile, fluorocarbon, and silicone offer varied resistance to chemicals and temperatures. Knowing which material suits your environment ensures optimum performance.

Another important feature is the size range. O-rings come in multiple dimensions. A precise fit is crucial. An improper size may lead to leaks or failures. Check the standard sizes and also consider custom options for unique applications.

Tips: Always inspect the seal before installation. Look for any visible damage or imperfections. A small flaw can compromise the seal's effectiveness. Additionally, keep your workspace clean to avoid contamination during installation.

Compression set is also a vital feature. It refers to how well an O-ring maintains its shape after being compressed. A lower compression set signifies better resilience. This factor impacts long-term performance and durability, which can save time and costs in maintenance.

Tips: Monitor the sealing performance over time. If leakage occurs, reevaluate the chosen O-ring. Adjustments may be needed based on operating conditions. Choosing the right O-ring involves understanding these features. Failure to do so can lead to costly mistakes.

When it comes to sealing solutions, O-ring seals play a crucial role across various industries. The right selection can enhance durability and performance. Here are some top choices for different applications.

In the automotive sector, one popular type is the silicone O-ring seal. It offers excellent resistance to high temperatures. However, it might not perform well in high-pressure situations. Remember to assess your specific needs before finalizing your choice.

For the food industry, EPDM O-rings are often recommended. They are safe for use with food products and withstand cleaning chemicals. However, they have limitations regarding oil resistance. Consider your operational environment when choosing materials.

Tips: Always verify compatibility with the substances your seals will encounter. Regular inspections are vital to identify wear and potential failure points. Additionally, proper installation can significantly extend the life of your O-ring seals. Make sure to follow the correct procedures for optimal performance.

This chart displays the performance indicators for five different O Ring seals used across various industries, including automotive, aerospace, medical, oil and gas, and food processing. The data represents their resistance levels to temperature, pressure, and chemical exposure.

When choosing O-ring seals, material selection is key. Different materials offer unique benefits and drawbacks. For example, nitrile rubber is popular for its resistance to oils and fuel. It performs well in moderate temperatures and pressures. However, its longevity may fall short in extreme conditions. In contrast, fluorocarbon O-rings excel in high-temperature applications. They resist chemical breakdown but can be costlier.

Comparing other materials reveals varying performance metrics. Silicone O-rings provide excellent flexibility and temperature tolerance, making them ideal for certain applications. Still, their mechanical strength might not meet all industrial needs. EPDM O-rings, known for their excellent weathering resistance, can lose elasticity over time. Each material has its application spectrum, making informed choices crucial.

Understanding your specific application requirements is vital. An unsuitable O-ring can lead to leakage, material failure, or unexpected downtime. Industry reports indicate that improper sealing solutions contribute to over 30% of mechanical failures. Hence, a thorough evaluation of material properties against application demands is essential for longevity and reliability.

| Material Type | Temperature Range (°C) | Chemical Resistance | Shore Hardness | Applications |

|---|---|---|---|---|

| Nitrile (NBR) | -40 to 100 | Oil, Grease | 70-90 | Automotive, Hydraulic Seals |

| Fluoroelastomer (FKM) | -20 to 200 | Chemicals, Fuels | 75-90 | Chemical Processing, Aerospace |

| Silicone | -50 to 200 | Water, Air | 30-80 | Food Industry, Medical |

| Polyurethane (PU) | -30 to 90 | Oils, Greases | 85-95 | High-Performance Seals |

| Ethylene Propylene (EPDM) | -50 to 150 | Steam, Water, Weather | 60-80 | HVAC, Water Applications |

Choosing the right O-ring seal involves understanding your application's specific needs. Seals made from different materials offer unique properties, impacting performance in various environments. For example, Nitrile O-rings are commonly used due to their excellent resistance to oils and fuels. In contrast, Fluorocarbon options excel in high-temperature scenarios.

According to industry reports, O-rings account for a significant percentage of sealing solutions, with a projected market growth of over 5% annually. However, many engineers still choose unsuitable materials, leading to premature seal failure. Aiming for a perfect fit is essential but can be challenging due to varied operational conditions.

Moreover, it’s worth noting how different sizes can affect sealing performance. A seemingly small variance in diameter can result in leaks. In one study, up to 30% of O-ring failures were attributed to size mismatches. Thus, careful measurement remains crucial for sealing efficiency.

It’s important to analyze the material properties, application environment, and specific requirements before making a selection.