Automotive parts fuel pump

-

01Excellent oil resistance: Fluororubber has excellent resistance to automotive fuels (such as gasoline, diesel, etc.), lubricants, hydraulic oils, etc. By being able to maintain the physical properties and shape of rubber in long-term contact with these oil substances, it is less prone to swelling, softening, or hardening, ensuring the sealing effect and service life of the seals.Good high temperature resistance: It can maintain stable performance in high temperature environments, generally able to withstand high temperatures of around 200 ℃, and some specially formulated fluororubber can even withstand higher temperatures. This enables it to adapt to working environments in high-temperature areas such as the engine compartment of automobiles. For example, even in situations where the engine runs for a long time and generates high temperatures, fluororubber seals can still function normally without losing their sealing function due to high temperatures.

01Excellent oil resistance: Fluororubber has excellent resistance to automotive fuels (such as gasoline, diesel, etc.), lubricants, hydraulic oils, etc. By being able to maintain the physical properties and shape of rubber in long-term contact with these oil substances, it is less prone to swelling, softening, or hardening, ensuring the sealing effect and service life of the seals.Good high temperature resistance: It can maintain stable performance in high temperature environments, generally able to withstand high temperatures of around 200 ℃, and some specially formulated fluororubber can even withstand higher temperatures. This enables it to adapt to working environments in high-temperature areas such as the engine compartment of automobiles. For example, even in situations where the engine runs for a long time and generates high temperatures, fluororubber seals can still function normally without losing their sealing function due to high temperatures. -

02Excellent chemical stability: It has corrosion resistance to most chemical substances, including acids, bases, oxidants, etc. In various working environments of automobiles, whether in contact with additives in engine coolant or various chemical components in fuel, fluororubber can maintain stability and is not easily corroded by chemicals, thereby ensuring the reliability and safety of components.Good mechanical performance: It has high hardness, strength, and wear resistance, and can withstand certain pressure and friction. During the operation of components such as fuel pumps and water pumps, fluororubber seals can withstand the pressure of the medium and are less prone to wear, tear, and other damage during the movement and friction of the components, ensuring the integrity and sealing performance of the seals.

02Excellent chemical stability: It has corrosion resistance to most chemical substances, including acids, bases, oxidants, etc. In various working environments of automobiles, whether in contact with additives in engine coolant or various chemical components in fuel, fluororubber can maintain stability and is not easily corroded by chemicals, thereby ensuring the reliability and safety of components.Good mechanical performance: It has high hardness, strength, and wear resistance, and can withstand certain pressure and friction. During the operation of components such as fuel pumps and water pumps, fluororubber seals can withstand the pressure of the medium and are less prone to wear, tear, and other damage during the movement and friction of the components, ensuring the integrity and sealing performance of the seals.

-

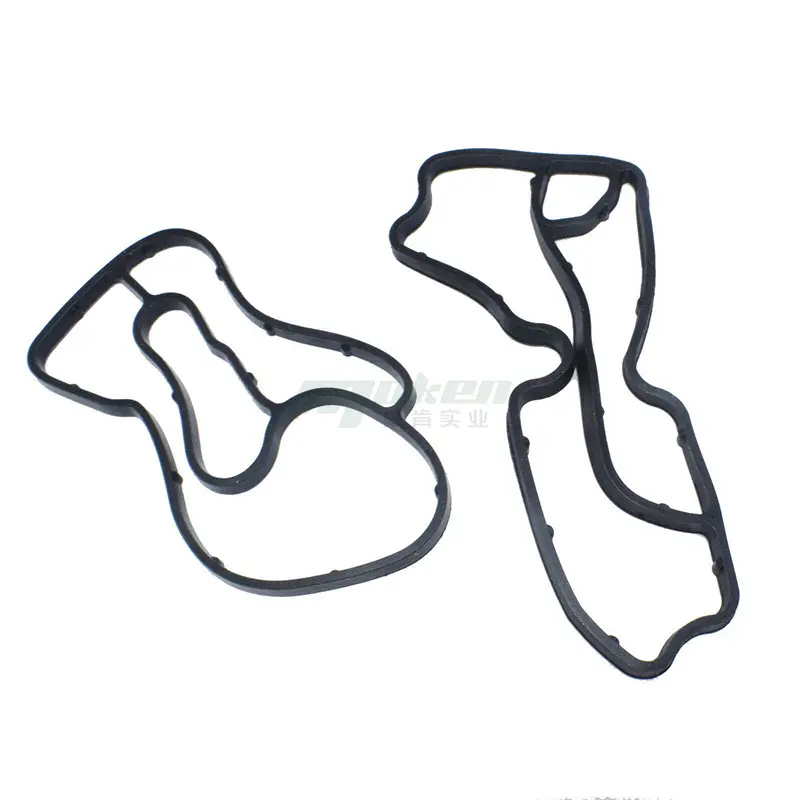

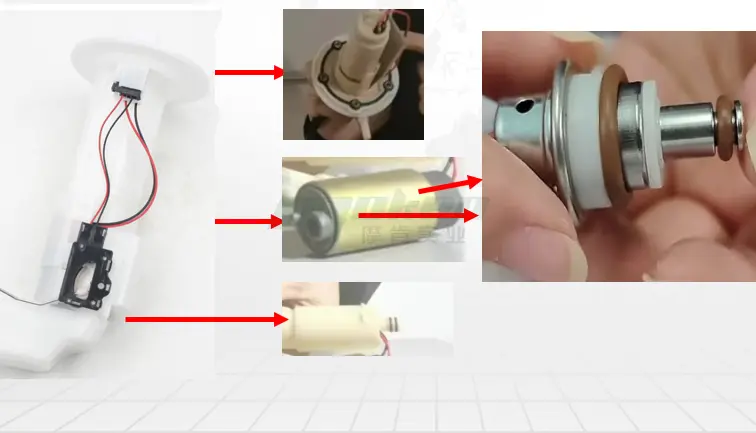

011. Fuel pumps for automobiles and motorcycles:Sealing gasket: used at the connection between the fuel pump and the fuel tank to prevent fuel leakage. The oil resistance and chemical stability of fluororubber ensure that it will not be damaged by fuel erosion in long-term contact with fuel, ensuring the sealing and safety of the fuel system.Diaphragm: In the operation of a fuel pump, the diaphragm plays a role in controlling fuel flow and pressure. The good elasticity and oil resistance of fluororubber enable it to maintain stable performance and accurately control fuel delivery during repeated stretching movements.

011. Fuel pumps for automobiles and motorcycles:Sealing gasket: used at the connection between the fuel pump and the fuel tank to prevent fuel leakage. The oil resistance and chemical stability of fluororubber ensure that it will not be damaged by fuel erosion in long-term contact with fuel, ensuring the sealing and safety of the fuel system.Diaphragm: In the operation of a fuel pump, the diaphragm plays a role in controlling fuel flow and pressure. The good elasticity and oil resistance of fluororubber enable it to maintain stable performance and accurately control fuel delivery during repeated stretching movements. -

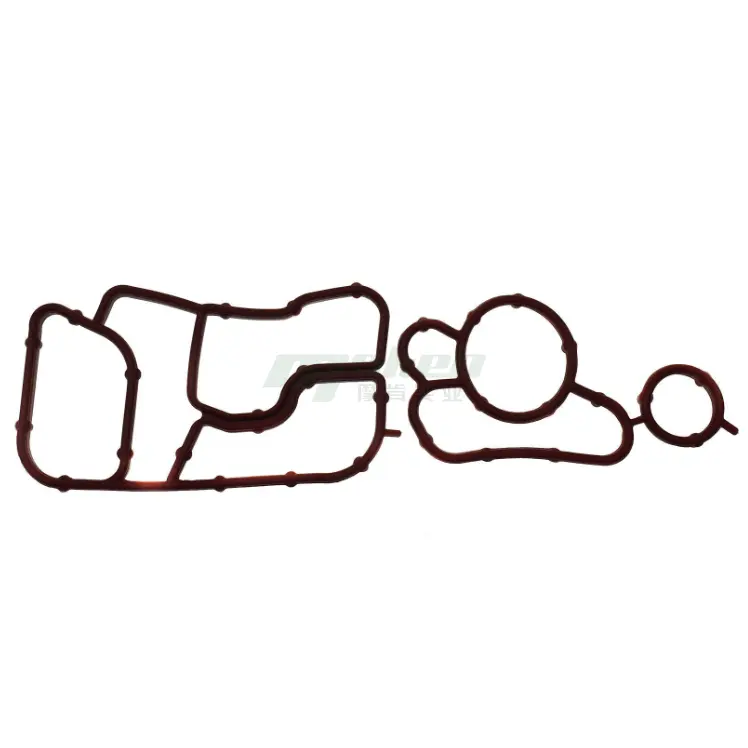

02At the pressure regulating valve: The fuel pump pressure regulating valve needs to precisely control the fuel pressure. FKM seals have excellent fuel resistance and can resist various chemical components in fuel, ensuring stable performance in long-term contact with fuel. At the same time, it can withstand certain pressure and temperature changes. When the fuel pump is working, it can adapt to the temperature rise caused by fuel flow and pressure regulation, maintain good sealing performance, prevent fuel leakage, maintain the normal operation of the pressure regulating valve, and ensure the stability of the fuel system pressure.

02At the pressure regulating valve: The fuel pump pressure regulating valve needs to precisely control the fuel pressure. FKM seals have excellent fuel resistance and can resist various chemical components in fuel, ensuring stable performance in long-term contact with fuel. At the same time, it can withstand certain pressure and temperature changes. When the fuel pump is working, it can adapt to the temperature rise caused by fuel flow and pressure regulation, maintain good sealing performance, prevent fuel leakage, maintain the normal operation of the pressure regulating valve, and ensure the stability of the fuel system pressure. -

03Pump core joint: The pump core joint is a key connection part of the fuel pump, and FKM seals play a reliable sealing role here to prevent fuel leakage at the connection between the pump core and other components. Its excellent wear resistance and anti-aging performance can withstand the friction and vibration of the joint during the long-term operation of the fuel pump, maintain the integrity of the seal, and ensure that the pump core can efficiently and stably deliver fuel to the engine.Assembly rubber seal: mainly used for sealing the interface between the fuel pump assembly and the fuel tank or other related components. It can effectively prevent fuel leakage from the interface to the outside, avoiding waste and safety hazards caused by fuel evaporation. At the same time, it can also prevent impurities such as dust and moisture from entering the interior of the fuel pump assembly, protect the internal components of the fuel pump from pollution and corrosion, and extend the service life of the fuel pump.

03Pump core joint: The pump core joint is a key connection part of the fuel pump, and FKM seals play a reliable sealing role here to prevent fuel leakage at the connection between the pump core and other components. Its excellent wear resistance and anti-aging performance can withstand the friction and vibration of the joint during the long-term operation of the fuel pump, maintain the integrity of the seal, and ensure that the pump core can efficiently and stably deliver fuel to the engine.Assembly rubber seal: mainly used for sealing the interface between the fuel pump assembly and the fuel tank or other related components. It can effectively prevent fuel leakage from the interface to the outside, avoiding waste and safety hazards caused by fuel evaporation. At the same time, it can also prevent impurities such as dust and moisture from entering the interior of the fuel pump assembly, protect the internal components of the fuel pump from pollution and corrosion, and extend the service life of the fuel pump. -

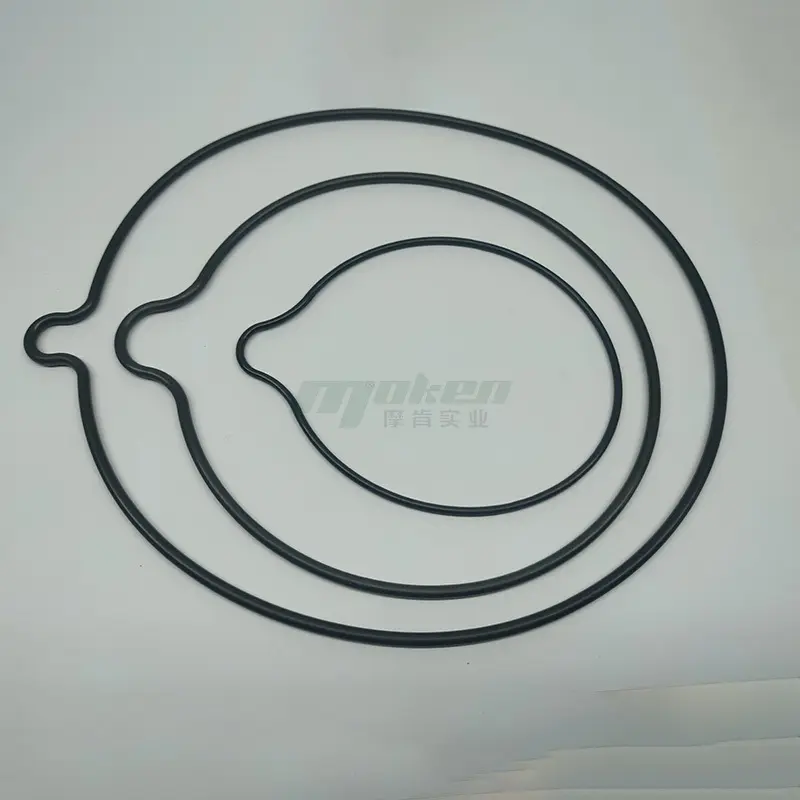

04Rubber airbag or rubber umbrella ring at the bottom of the assemblyRubber airbags: generally serve as cushioning and compensation. When the fuel pump is working, it may generate certain vibrations and pressure fluctuations. The rubber airbag can absorb these vibrations and pressure changes through its own elastic deformation, reducing the impact on the fuel pump assembly and surrounding components, and protecting the structural integrity of the fuel pump. In addition, the airbag can also play a certain compensatory role when the fuel level changes, maintaining stable pressure inside the fuel pump and ensuring the continuity of fuel supply.

04Rubber airbag or rubber umbrella ring at the bottom of the assemblyRubber airbags: generally serve as cushioning and compensation. When the fuel pump is working, it may generate certain vibrations and pressure fluctuations. The rubber airbag can absorb these vibrations and pressure changes through its own elastic deformation, reducing the impact on the fuel pump assembly and surrounding components, and protecting the structural integrity of the fuel pump. In addition, the airbag can also play a certain compensatory role when the fuel level changes, maintaining stable pressure inside the fuel pump and ensuring the continuity of fuel supply. -

05Rubber umbrella ring: usually used to enhance the sealing effect at the bottom of the assembly, preventing fuel leakage from the bottom. Its shape design can better adapt to the structure at the bottom of the assembly, providing more reliable sealing. At the same time, during the installation and operation of the fuel pump, the umbrella ring can withstand certain pressure and deformation, maintain good sealing performance, and avoid fuel leakage to other parts of the vehicle.

05Rubber umbrella ring: usually used to enhance the sealing effect at the bottom of the assembly, preventing fuel leakage from the bottom. Its shape design can better adapt to the structure at the bottom of the assembly, providing more reliable sealing. At the same time, during the installation and operation of the fuel pump, the umbrella ring can withstand certain pressure and deformation, maintain good sealing performance, and avoid fuel leakage to other parts of the vehicle. -

2. Water tankRadiator gasket: installed at the connection between the radiator and the engine block or other components to prevent coolant leakage. The water resistance and chemical resistance of fluororubber enable it to adapt to the composition of coolant and maintain good sealing performance in high-temperature environments during engine operation, ensuring the normal operation of the cooling system.Sealing element for water tank cover: Ensure the sealing between the water tank cover and the water tank to prevent coolant from overflowing at high temperatures. Fluororubber seals can withstand pressure changes and temperature fluctuations inside the water tank, effectively maintaining pressure balance in the cooling system and improving cooling efficiency.

2. Water tankRadiator gasket: installed at the connection between the radiator and the engine block or other components to prevent coolant leakage. The water resistance and chemical resistance of fluororubber enable it to adapt to the composition of coolant and maintain good sealing performance in high-temperature environments during engine operation, ensuring the normal operation of the cooling system.Sealing element for water tank cover: Ensure the sealing between the water tank cover and the water tank to prevent coolant from overflowing at high temperatures. Fluororubber seals can withstand pressure changes and temperature fluctuations inside the water tank, effectively maintaining pressure balance in the cooling system and improving cooling efficiency. -

3. Fuel tankFuel tank sealing gasket: used for the fuel filling port, drain port, and connection between the fuel tank and other pipelines to prevent fuel leakage and volatilization. The oil resistance and aging resistance of fluororubber enable it to maintain sealing performance in environments where fuel is stored for a long time, reducing fuel loss and environmental pollution.Oil tank diaphragm: Some fuel tanks use fluororubber diaphragms to separate different areas or provide cushioning. The diaphragm needs to have good flexibility and fuel resistance to adapt to the shaking and temperature changes of the fuel in the tank, while preventing fuel leakage.

3. Fuel tankFuel tank sealing gasket: used for the fuel filling port, drain port, and connection between the fuel tank and other pipelines to prevent fuel leakage and volatilization. The oil resistance and aging resistance of fluororubber enable it to maintain sealing performance in environments where fuel is stored for a long time, reducing fuel loss and environmental pollution.Oil tank diaphragm: Some fuel tanks use fluororubber diaphragms to separate different areas or provide cushioning. The diaphragm needs to have good flexibility and fuel resistance to adapt to the shaking and temperature changes of the fuel in the tank, while preventing fuel leakage. -

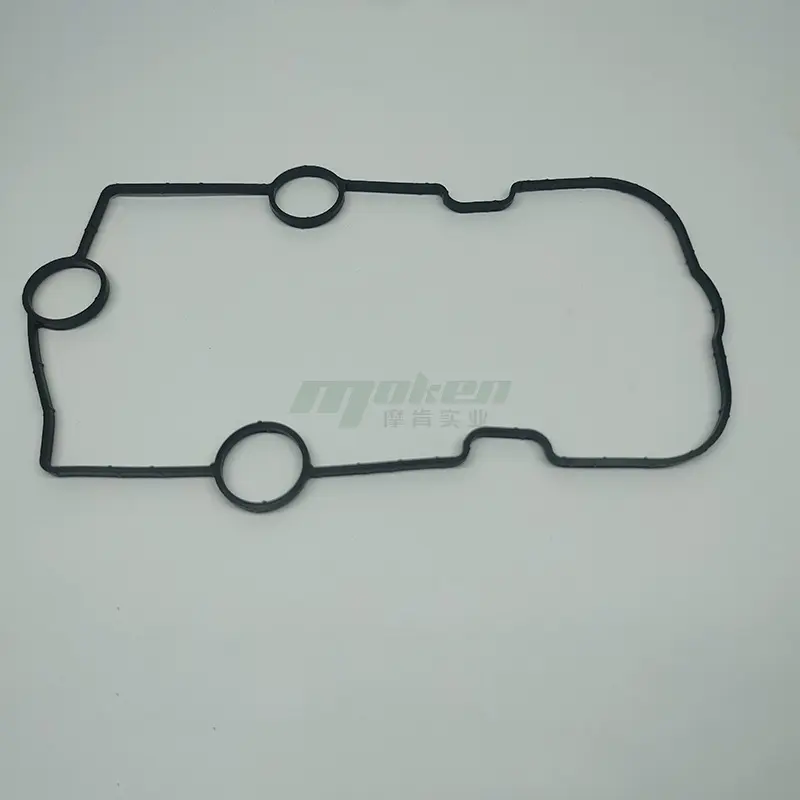

4. Water pump, oil pumpShaft seal: used for the shaft of water pumps and oil pumps to prevent liquid leakage. Fluororubber shaft seals have good wear resistance and corrosion resistance, which can maintain a tight seal during high-speed rotation of the shaft, prevent coolant or lubricating oil leakage, and ensure the normal operation of water pumps and oil pumps.Sealing ring: installed between the pump body and impeller or other components to provide a sealing effect. Fluorine rubber sealing rings can withstand the pressure and medium flushing during pump operation, and their good elasticity and sealing performance ensure the efficient operation of the pump, reducing energy loss and medium waste caused by leakage.

4. Water pump, oil pumpShaft seal: used for the shaft of water pumps and oil pumps to prevent liquid leakage. Fluororubber shaft seals have good wear resistance and corrosion resistance, which can maintain a tight seal during high-speed rotation of the shaft, prevent coolant or lubricating oil leakage, and ensure the normal operation of water pumps and oil pumps.Sealing ring: installed between the pump body and impeller or other components to provide a sealing effect. Fluorine rubber sealing rings can withstand the pressure and medium flushing during pump operation, and their good elasticity and sealing performance ensure the efficient operation of the pump, reducing energy loss and medium waste caused by leakage.

-

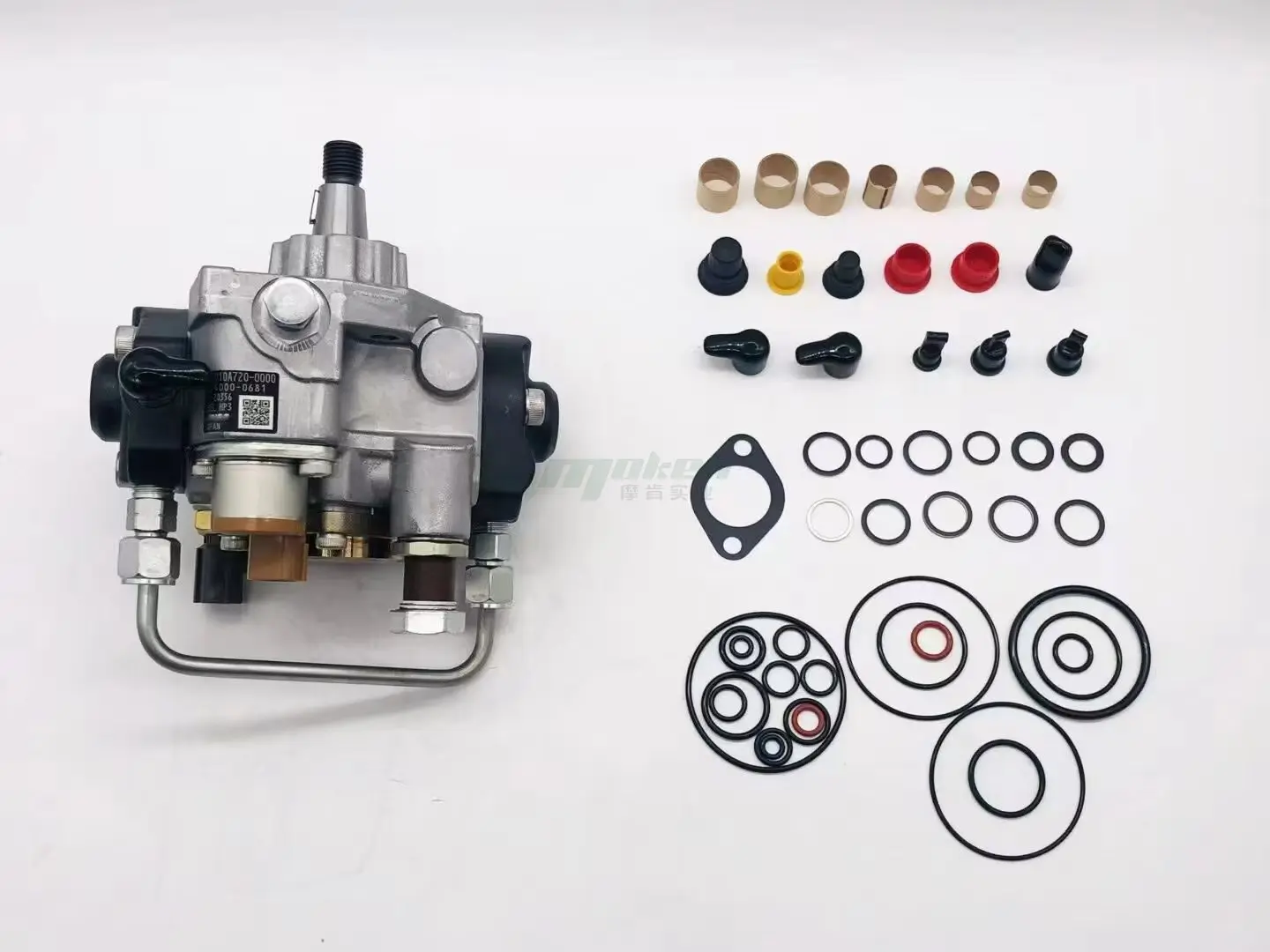

011. Fuel pump system1. Pressure regulating valve sealRecommended Material: FKM (Fluororubber)Reason: It needs to withstand long-term immersion in fuel (gasoline/diesel), high-pressure environment, and temperature fluctuations (120-150 ℃). FKM's oil resistance, high temperature resistance, and chemical corrosion resistance are the most compatible.Alternative solution: None (other materials such as NBR are insufficient in terms of flame resistance).2. Sealing components for pump core jointsRecommended material: FKMReason: It is necessary to resist fuel erosion, high-pressure pulses, and mechanical vibrations. FKM's high strength and wear resistance ensure long-term reliable sealing.Alternative solution: None (NBR is prone to swelling, silicone is not oil resistant).

011. Fuel pump system1. Pressure regulating valve sealRecommended Material: FKM (Fluororubber)Reason: It needs to withstand long-term immersion in fuel (gasoline/diesel), high-pressure environment, and temperature fluctuations (120-150 ℃). FKM's oil resistance, high temperature resistance, and chemical corrosion resistance are the most compatible.Alternative solution: None (other materials such as NBR are insufficient in terms of flame resistance).2. Sealing components for pump core jointsRecommended material: FKMReason: It is necessary to resist fuel erosion, high-pressure pulses, and mechanical vibrations. FKM's high strength and wear resistance ensure long-term reliable sealing.Alternative solution: None (NBR is prone to swelling, silicone is not oil resistant). -

023. Assembly mouth sealRecommended materials: FKM or NBR (nitrile rubber)OFKM: Suitable for high-temperature, highly corrosive fuel environments (such as ethanol gasoline).ONBR: Low cost, suitable for scenarios with ordinary fuel (no ethanol) and temperature ≤ 100 ℃.Attention: NBR has lower oil resistance than FKM and needs to be replaced regularly.4. Bottom airbag/umbrella ringRecommended materials: FKM or HNBR (hydrogenated nitrile rubber)FKM: High temperature and fuel resistance, but slightly lower elasticity.HNBR: It has better elasticity, oil resistance, and aging resistance similar to FKM, making it suitable for airbag structures that require dynamic compensation.Alternative solution: EPDM (ethylene propylene diene monomer rubber) is only suitable for non fuel contact scenarios.

023. Assembly mouth sealRecommended materials: FKM or NBR (nitrile rubber)OFKM: Suitable for high-temperature, highly corrosive fuel environments (such as ethanol gasoline).ONBR: Low cost, suitable for scenarios with ordinary fuel (no ethanol) and temperature ≤ 100 ℃.Attention: NBR has lower oil resistance than FKM and needs to be replaced regularly.4. Bottom airbag/umbrella ringRecommended materials: FKM or HNBR (hydrogenated nitrile rubber)FKM: High temperature and fuel resistance, but slightly lower elasticity.HNBR: It has better elasticity, oil resistance, and aging resistance similar to FKM, making it suitable for airbag structures that require dynamic compensation.Alternative solution: EPDM (ethylene propylene diene monomer rubber) is only suitable for non fuel contact scenarios. -

032. Water tank and cooling system1. Heat sink gasketRecommended materials: EPDM or FKMEPDM: resistant to coolant (ethylene glycol based), ozone aging, low cost, suitable for room temperature environment.FKM: High temperature resistance (above 150 ℃), suitable for high-temperature areas such as turbocharged engines.2. Water tank cover sealRecommended materials: EPDM or siliconeEPDM: resistant to water and pressure changes, with high cost-effectiveness. Silicone: High temperature resistant (200 ℃+), suitable for high-pressure and high-temperature water tanks, but poor oil resistance (avoid contact with oil stains).

032. Water tank and cooling system1. Heat sink gasketRecommended materials: EPDM or FKMEPDM: resistant to coolant (ethylene glycol based), ozone aging, low cost, suitable for room temperature environment.FKM: High temperature resistance (above 150 ℃), suitable for high-temperature areas such as turbocharged engines.2. Water tank cover sealRecommended materials: EPDM or siliconeEPDM: resistant to water and pressure changes, with high cost-effectiveness. Silicone: High temperature resistant (200 ℃+), suitable for high-pressure and high-temperature water tanks, but poor oil resistance (avoid contact with oil stains). -

043. Fuel tank system1. Fuel tank sealing gasketRecommended materials: FKM or NBRFKM: resistant to oil penetration and aging, suitable for long-term sealing.NBR: Low cost, suitable for ordinary fuel environments (such as traditional gasoline).2. Diaphragm inside the fuel tankRecommended materials: FKM or fluorosilicone rubberFKM: resistant to fuel and high pressure.Fluorosilicone rubber: better flexibility, suitable for dynamic environments (such as motorcycle fuel tank bumps), but higher cost.

043. Fuel tank system1. Fuel tank sealing gasketRecommended materials: FKM or NBRFKM: resistant to oil penetration and aging, suitable for long-term sealing.NBR: Low cost, suitable for ordinary fuel environments (such as traditional gasoline).2. Diaphragm inside the fuel tankRecommended materials: FKM or fluorosilicone rubberFKM: resistant to fuel and high pressure.Fluorosilicone rubber: better flexibility, suitable for dynamic environments (such as motorcycle fuel tank bumps), but higher cost. -

4. Water pump and oil pump1. Shaft sealRecommended materials: FKM or NBRFKM: High temperature resistant, oil resistant, suitable for oil pumps.NBR: Water resistant, weakly corrosion-resistant, suitable for water pumps (coolant composition needs to be confirmed).2. Sealing ringRecommended materials: FKM or polyurethane (PU)FKM: High pressure resistant, oil resistant, suitable for oil pumps.PU: High elasticity, wear-resistant, suitable for low-pressure and low-speed water pumps.

4. Water pump and oil pump1. Shaft sealRecommended materials: FKM or NBRFKM: High temperature resistant, oil resistant, suitable for oil pumps.NBR: Water resistant, weakly corrosion-resistant, suitable for water pumps (coolant composition needs to be confirmed).2. Sealing ringRecommended materials: FKM or polyurethane (PU)FKM: High pressure resistant, oil resistant, suitable for oil pumps.PU: High elasticity, wear-resistant, suitable for low-pressure and low-speed water pumps. -

5.Summary of Material Selection

5.Summary of Material Selection -

6. Selection SuggestionsPrioritize FKM: suitable for core components that come into contact with fuel, high temperatures, and chemical corrosion (such as fuel pumps and oil pumps).Reasonable use of alternative materials: In non critical or low-cost scenarios (such as ordinary water tanks, non ethanol fuel tanks), NBR, EPDM, or PU can be chosen to reduce costs.Dynamic scene optimization: HNBR (hydrogenated nitrile rubber) maintains FKM performance while having better elasticity, making it suitable for dynamic compensation structures such as airbags and diaphragms.By balancing material performance and cost, the optimal solution of economy and reliability can be achieved while ensuring safety.

6. Selection SuggestionsPrioritize FKM: suitable for core components that come into contact with fuel, high temperatures, and chemical corrosion (such as fuel pumps and oil pumps).Reasonable use of alternative materials: In non critical or low-cost scenarios (such as ordinary water tanks, non ethanol fuel tanks), NBR, EPDM, or PU can be chosen to reduce costs.Dynamic scene optimization: HNBR (hydrogenated nitrile rubber) maintains FKM performance while having better elasticity, making it suitable for dynamic compensation structures such as airbags and diaphragms.By balancing material performance and cost, the optimal solution of economy and reliability can be achieved while ensuring safety.