Silicone rubber seals for automotive cable systems

-

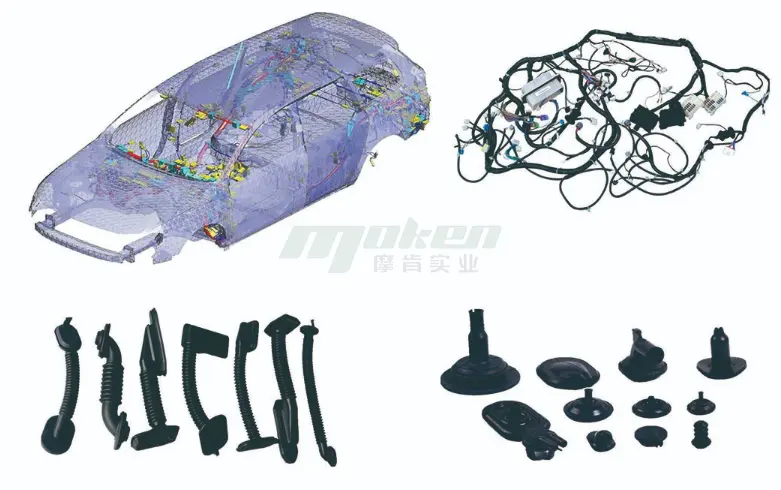

01Rubber components for automotive control cables are made from high-performance rubber materials such as NBR (Nitrile Butadiene Rubber) and EPDM (Ethylene Propylene Diene Monomer). They have excellent temperature resistance ranging from -40°C to 150°C, as well as features of oil resistance and anti-aging, enabling them to withstand the harsh environment of the engine compartment. Through precision compression molding, these components can achieve waterproof and dustproof sealing, mechanical cushioning, and insulation protection.The entire production process strictly adheres to the IATF 16949 standard, with rigorous control from formulation to finished products, providing reliable connection guarantees for intelligent driving.

01Rubber components for automotive control cables are made from high-performance rubber materials such as NBR (Nitrile Butadiene Rubber) and EPDM (Ethylene Propylene Diene Monomer). They have excellent temperature resistance ranging from -40°C to 150°C, as well as features of oil resistance and anti-aging, enabling them to withstand the harsh environment of the engine compartment. Through precision compression molding, these components can achieve waterproof and dustproof sealing, mechanical cushioning, and insulation protection.The entire production process strictly adheres to the IATF 16949 standard, with rigorous control from formulation to finished products, providing reliable connection guarantees for intelligent driving. -

02The silicone rubber components of automotive wire harness protective sleeves offer a wide operating temperature range, enabling them to withstand diverse environmental conditions. With excellent sealing performance, they achieve an IP69K waterproof rating at connector interfaces, effectively preventing water and dust ingress. Additionally, silicone rubber features remarkable flexibility, insulation, and aging resistance. It cushions vibrations and safeguards high-speed data cables, power cords, and sensor networks, thereby extending the service life of automotive wire harnesses.00 - hour salt spray testing.

02The silicone rubber components of automotive wire harness protective sleeves offer a wide operating temperature range, enabling them to withstand diverse environmental conditions. With excellent sealing performance, they achieve an IP69K waterproof rating at connector interfaces, effectively preventing water and dust ingress. Additionally, silicone rubber features remarkable flexibility, insulation, and aging resistance. It cushions vibrations and safeguards high-speed data cables, power cords, and sensor networks, thereby extending the service life of automotive wire harnesses.00 - hour salt spray testing. -

03In the automotive braking system's silicone rubber seals, silicone rubber (VMQ/FVMQ) and polyurethane (PU) have become the core materials to ensure vehicle safety and comfort due to their unique properties. VMQ (Methyl Vinyl Silicone Rubber) has a wide temperature adaptability ranging from -60°C to 250°C, and is widely used in components such as brake caliper piston seals. After modification, FVMQ (Fluorosilicone Rubber) has significantly improved oil resistance and has become the preferred material for brake calipers in high - end vehicles. With high tensile strength, low friction coefficient and good wear resistance, PU materials play an important role in brake pedal pads and parking brake ratchet mechanisms.

03In the automotive braking system's silicone rubber seals, silicone rubber (VMQ/FVMQ) and polyurethane (PU) have become the core materials to ensure vehicle safety and comfort due to their unique properties. VMQ (Methyl Vinyl Silicone Rubber) has a wide temperature adaptability ranging from -60°C to 250°C, and is widely used in components such as brake caliper piston seals. After modification, FVMQ (Fluorosilicone Rubber) has significantly improved oil resistance and has become the preferred material for brake calipers in high - end vehicles. With high tensile strength, low friction coefficient and good wear resistance, PU materials play an important role in brake pedal pads and parking brake ratchet mechanisms. -

04The sealing and protection technology for automotive steering systems has advanced from basic protection to intelligent sensing through material innovation and structural optimization. We leverage our R&D capabilities in a full range of high-performance rubber materials (VMQ/FVMQ/FFKM/NBR/EPDM, etc.) to provide customers with one-stop solutions from design validation to mass production and delivery, ensuring the steering system remains stable and reliable over a 1.5 million cycle life and supporting safe mobility in the era of intelligent driving.

04The sealing and protection technology for automotive steering systems has advanced from basic protection to intelligent sensing through material innovation and structural optimization. We leverage our R&D capabilities in a full range of high-performance rubber materials (VMQ/FVMQ/FFKM/NBR/EPDM, etc.) to provide customers with one-stop solutions from design validation to mass production and delivery, ensuring the steering system remains stable and reliable over a 1.5 million cycle life and supporting safe mobility in the era of intelligent driving. -

05Rubber seals for automotive reversing radars typically use silicone rubber and EPDM (Ethylene Propylene Diene Monomer) rubber. Silicone rubber withstands extreme temperatures from -60°C to 200°C with excellent chemical stability, ensuring long service life; EPDM rubber resists aging and ozone, defending against environmental damage. Their core function is to prevent water, dust, and foreign substances from invading the radar’s interior, protecting electronic components from moisture or performance degradation caused by debris. Additionally, the rubber’s elasticity cushions vibrations and reduces noise interference, enabling the radar to accurately detect rear obstacles and enhance reversing safety and reliability.

05Rubber seals for automotive reversing radars typically use silicone rubber and EPDM (Ethylene Propylene Diene Monomer) rubber. Silicone rubber withstands extreme temperatures from -60°C to 200°C with excellent chemical stability, ensuring long service life; EPDM rubber resists aging and ozone, defending against environmental damage. Their core function is to prevent water, dust, and foreign substances from invading the radar’s interior, protecting electronic components from moisture or performance degradation caused by debris. Additionally, the rubber’s elasticity cushions vibrations and reduces noise interference, enabling the radar to accurately detect rear obstacles and enhance reversing safety and reliability.