Automotive rubber parts

-

01Anti-Vibration Silicone Pads for Automotive Intelligent Imaging SystemsMade from high-elasticity silicone material, these pads feature excellent resistance to extreme temperatures (-50°C to 200°C) and aging, effectively absorbing high-frequency vibrations during vehicle operation (attenuation rate ≥85%). This prevents image blur or data transmission interference caused by lens shaking. Their precision compression-molded curved surface structures fit tightly with device interfaces, providing IP67-rated auxiliary protection while offering insulation and weather resistance. Designed to operate stably under complex conditions, they enhance the reliability of intelligent driving assistance systems and the clarity of captured imagery.

01Anti-Vibration Silicone Pads for Automotive Intelligent Imaging SystemsMade from high-elasticity silicone material, these pads feature excellent resistance to extreme temperatures (-50°C to 200°C) and aging, effectively absorbing high-frequency vibrations during vehicle operation (attenuation rate ≥85%). This prevents image blur or data transmission interference caused by lens shaking. Their precision compression-molded curved surface structures fit tightly with device interfaces, providing IP67-rated auxiliary protection while offering insulation and weather resistance. Designed to operate stably under complex conditions, they enhance the reliability of intelligent driving assistance systems and the clarity of captured imagery. -

02Rubber components for automotive lighting systems are critical parts that directly impact the performance of lighting fixtures and driving safety. They exhibit excellent sealing performance, effectively blocking the intrusion of dust, rainwater, and moisture to prevent electrical failures and extend the service life of the lighting. Additionally, these components feature outstanding resistance to oil, acids/alkalis, extreme temperatures, and aging, maintaining stable physical properties in harsh environments without hardening, cracking, or deforming.

02Rubber components for automotive lighting systems are critical parts that directly impact the performance of lighting fixtures and driving safety. They exhibit excellent sealing performance, effectively blocking the intrusion of dust, rainwater, and moisture to prevent electrical failures and extend the service life of the lighting. Additionally, these components feature outstanding resistance to oil, acids/alkalis, extreme temperatures, and aging, maintaining stable physical properties in harsh environments without hardening, cracking, or deforming. -

03Silicone rubber seals for new energy vehicle charging guns are critical safety components. They withstand -50°C to 200°C, resist UV/ozone aging, and are impervious to oil, acids, and alkalis. With excellent sealing, they block dust/water intrusion to prevent short circuits. Their elasticity cushions plugging/unplugging impacts, while high electrical insulation ensures user safety. Used at plug-port connections and housing gaps, they’re formed via compression molding and undergo strict quality checks to guarantee stable, safe charging.

03Silicone rubber seals for new energy vehicle charging guns are critical safety components. They withstand -50°C to 200°C, resist UV/ozone aging, and are impervious to oil, acids, and alkalis. With excellent sealing, they block dust/water intrusion to prevent short circuits. Their elasticity cushions plugging/unplugging impacts, while high electrical insulation ensures user safety. Used at plug-port connections and housing gaps, they’re formed via compression molding and undergo strict quality checks to guarantee stable, safe charging. -

Sealing Gaskets for New Energy Energy Storage Terminals04As key components ensuring safe and stable system operation, these gaskets adapt to various complex scenarios in new energy storage. They effectively isolate moisture, dust, and other impurities at lithium battery terminal connections, safeguarding charge/discharge safety and extending battery life. At socket connection terminals, they ensure tight connections to minimize energy loss and safety risks from poor contact, enabling efficient power transmission. In wall-penetrating connectors, they provide reliable sealing and insulation for electrical connections across different spaces.

Sealing Gaskets for New Energy Energy Storage Terminals04As key components ensuring safe and stable system operation, these gaskets adapt to various complex scenarios in new energy storage. They effectively isolate moisture, dust, and other impurities at lithium battery terminal connections, safeguarding charge/discharge safety and extending battery life. At socket connection terminals, they ensure tight connections to minimize energy loss and safety risks from poor contact, enabling efficient power transmission. In wall-penetrating connectors, they provide reliable sealing and insulation for electrical connections across different spaces. -

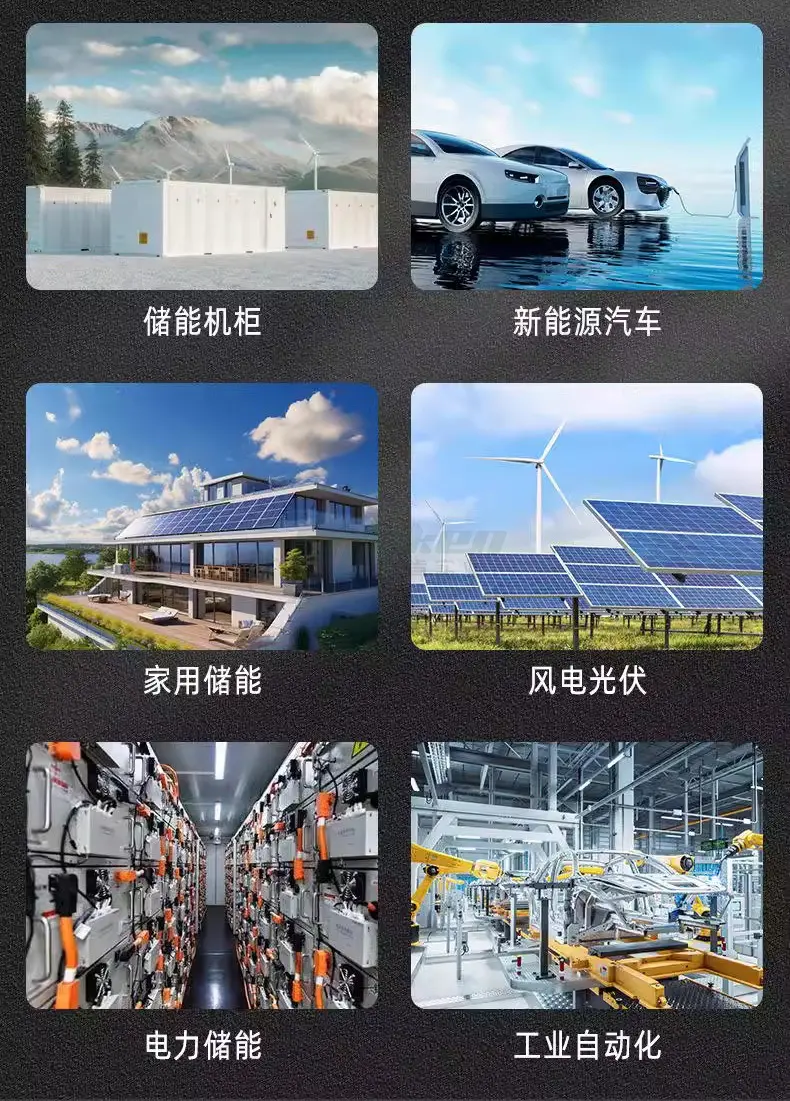

05Widely applied in energy storage cabinets, power/communication energy storage systems, residential, industrial/commercial, new energy vehicles, and wind/solar power sectors, these gaskets are made from flame-retardant rubber. They feature excellent corrosion resistance (withstanding chemical erosion), strong oxidation resistance (slowing material aging), superior weather resistance (stable in extreme temperatures and harsh environments), and outstanding aging resistance (maintaining performance over long periods). These properties form a solid safety barrier for the new energy storage industry.

05Widely applied in energy storage cabinets, power/communication energy storage systems, residential, industrial/commercial, new energy vehicles, and wind/solar power sectors, these gaskets are made from flame-retardant rubber. They feature excellent corrosion resistance (withstanding chemical erosion), strong oxidation resistance (slowing material aging), superior weather resistance (stable in extreme temperatures and harsh environments), and outstanding aging resistance (maintaining performance over long periods). These properties form a solid safety barrier for the new energy storage industry.