ACM/AEM + PU + CR + IIR + SBR + NR

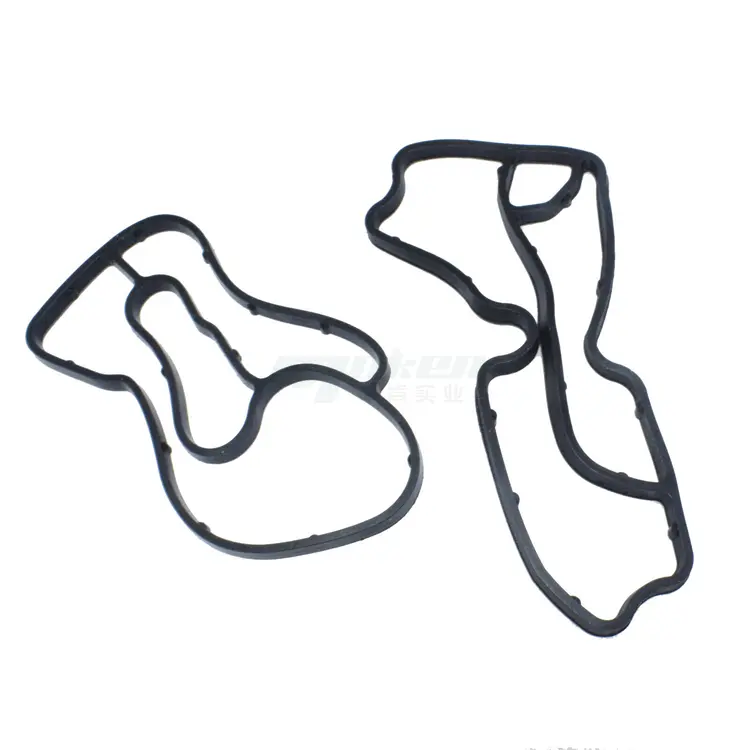

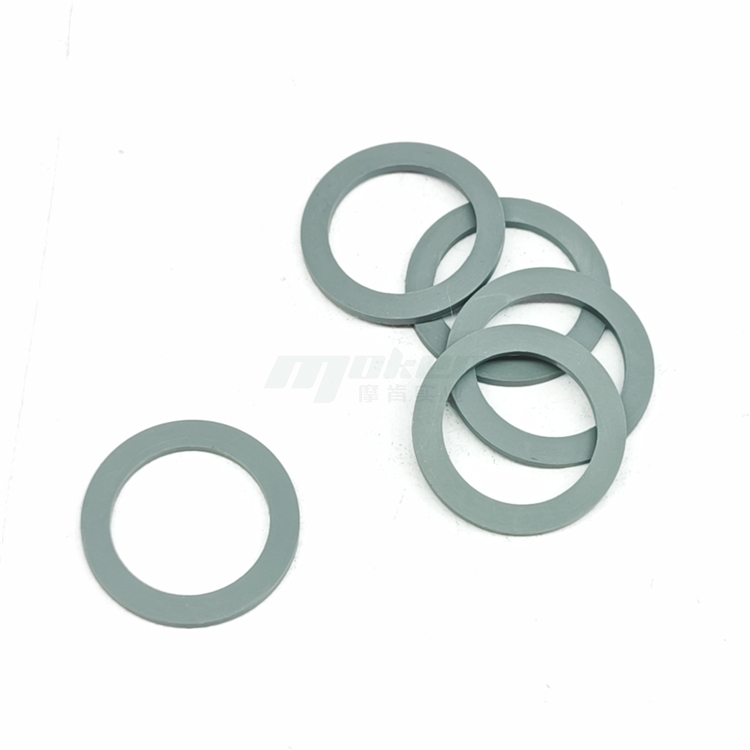

Polymerized from alkyl ester acrylate, ACM/AEM provides good resistance to petroleum oils, high temperatures, and weathering. However, it has lower mechanical strength, compression set, and water resistance. Oil resistance is inferior to standard oil-resistant rubbers. Operating temperature: -25~170℃ (special grades down to -40℃). Suitable for automotive transmission fluids, with resistance to oxidation, weathering, and bending. Used in transmission systems and power steering. Disadvantages: incompatible with hot water, brake fluid, low temperatures, and phosphate esters.

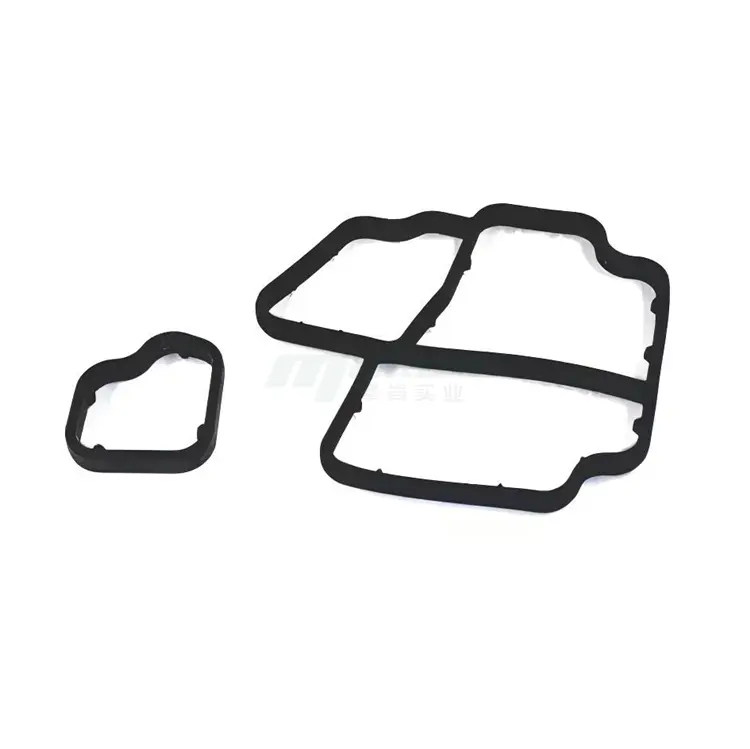

Polymerized from chloroprene monomer, CR offers good elastic and wear resistance after vulcanization. Resistant to sunlight, atmospheric aging, and refrigerant (e.g., dichlorodifluoromethane, ammonia), dilute acids, and silicone esters. Prone to low-temperature crystallization and poor storage stability. Swells significantly in low-aniline-point mineral oils. Operating temperature: -50~150℃. Advantages: good elasticity and compression set, sulfur-free formulation, resistance to animal/vegetable oils, flame retardancy. Disadvantages: incompatible with strong acids, nitrohydrocarbons, esters, chloroform, and ketones. Used in R12 refrigerant seals, household appliance parts, and flame/chemical-resistant products.

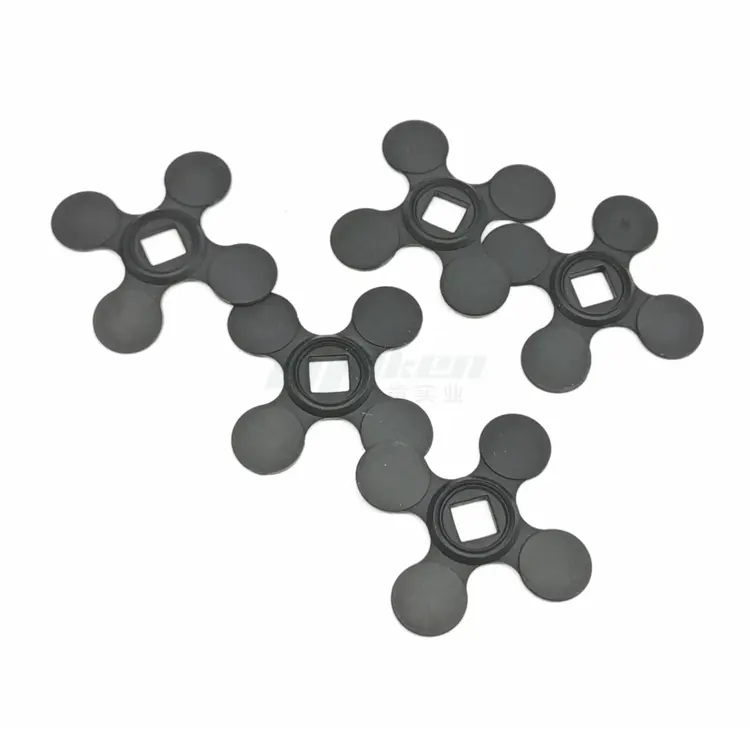

A copolymer of butadiene and styrene, SBR has more uniform quality and fewer impurities than natural rubber but lower mechanical strength. It is often blended with natural rubber. Advantages include low cost, non-oil resistance, and good water resistance (outstanding elasticity below 70 IRHD). It is suitable for neutral chemicals and dry/sticky organic ketones. Disadvantages: unsuitable for strong acids, ozone, oils, fats, and most hydrocarbons; poor compression set at high hardness. Widely used in tires, footwear, fabrics, and conveyor belts.

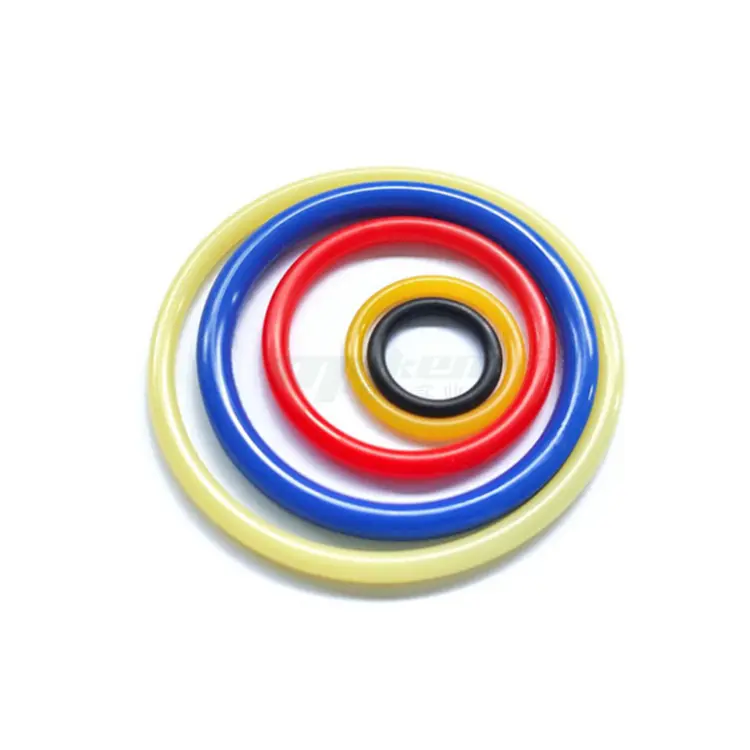

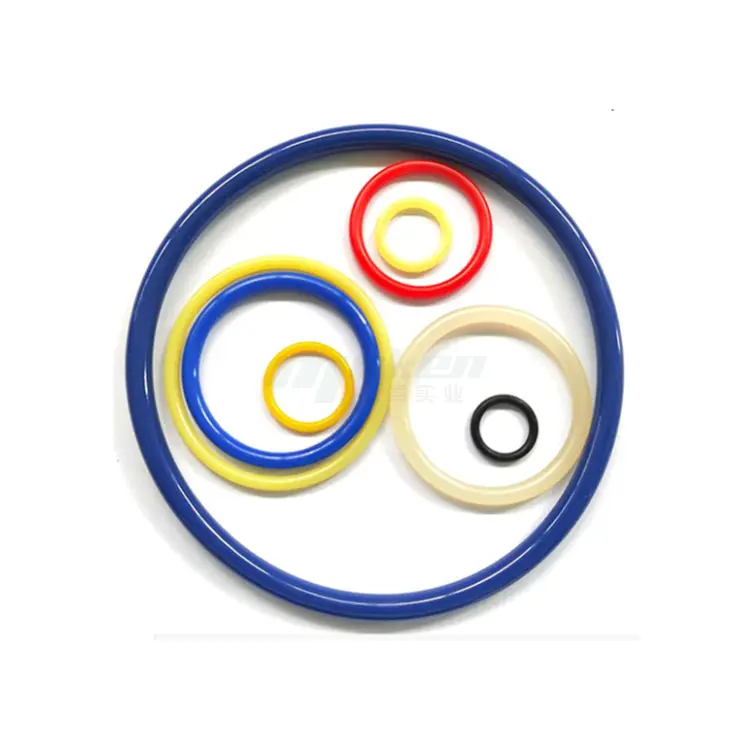

PU exhibits exceptional mechanical properties, including high hardness, elasticity, and abrasion resistance, along with aging, ozone, and oil resistance. Operating temperature: -45~90℃. Advantages: wear and high-pressure resistance. Disadvantages: poor high-temperature resistance. Used in high-pressure industrial seals (e.g., hydraulic cylinders) and high-voltage systems.

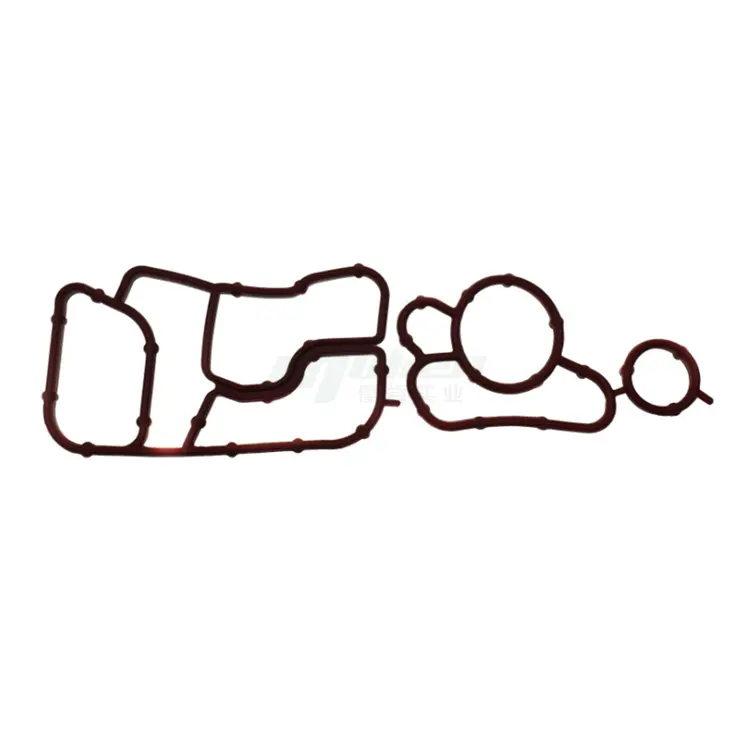

Polymerized from isobutylene with a small amount of isoprene, IIR retains slight unsaturation for vulcanization. Its methyl groups restrict molecular movement, providing low gas permeability, high resistance to heat, sunlight, and ozone, and excellent electrical insulation. It resists polar solvents (e.g., alcohols, ketones, esters). Operating temperature: -54~110℃. Advantages: impermeable to most gases, sunlight/ozone-resistant, compatible with animal/vegetable oils. Disadvantages: incompatible with petroleum solvents, kerosene, and aromatic hydrocarbons. Used in chemical-resistant and vacuum equipment rubber parts.

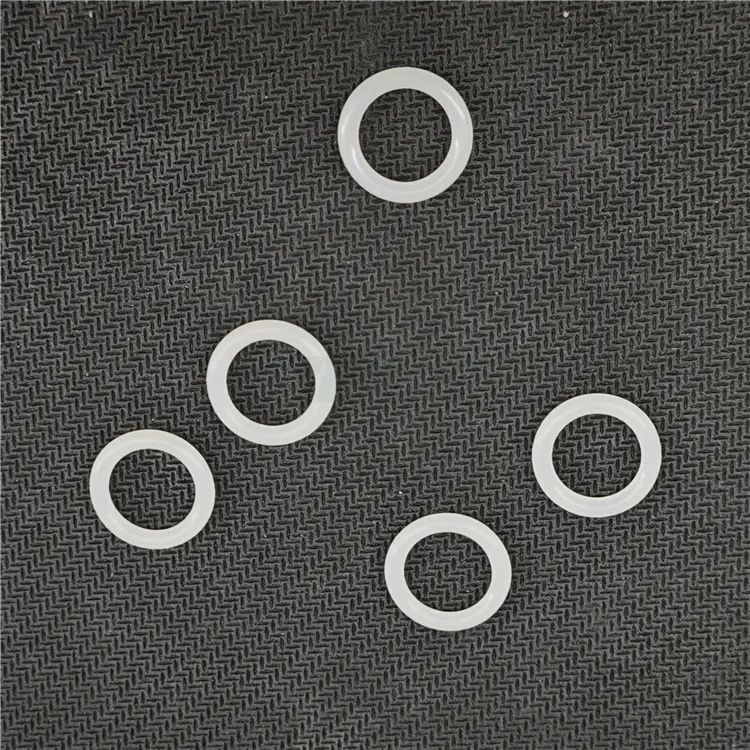

Derived from rubber tree latex, NR is an isoprene polymer with excellent abrasion resistance, high elasticity, tensile strength, and elongation. However, it ages easily in air, becomes sticky when heated, and swells/dissolves in mineral oil or gasoline. It resists alkalis but not strong acids. Used in belts, hoses, footwear, and shock-absorbing components exposed to hydroxyl-containing fluids (e.g., automotive brake fluid, ethanol).